The Importance of Circuit Board Components in PCB Assembly

Get Your PCB Quote!

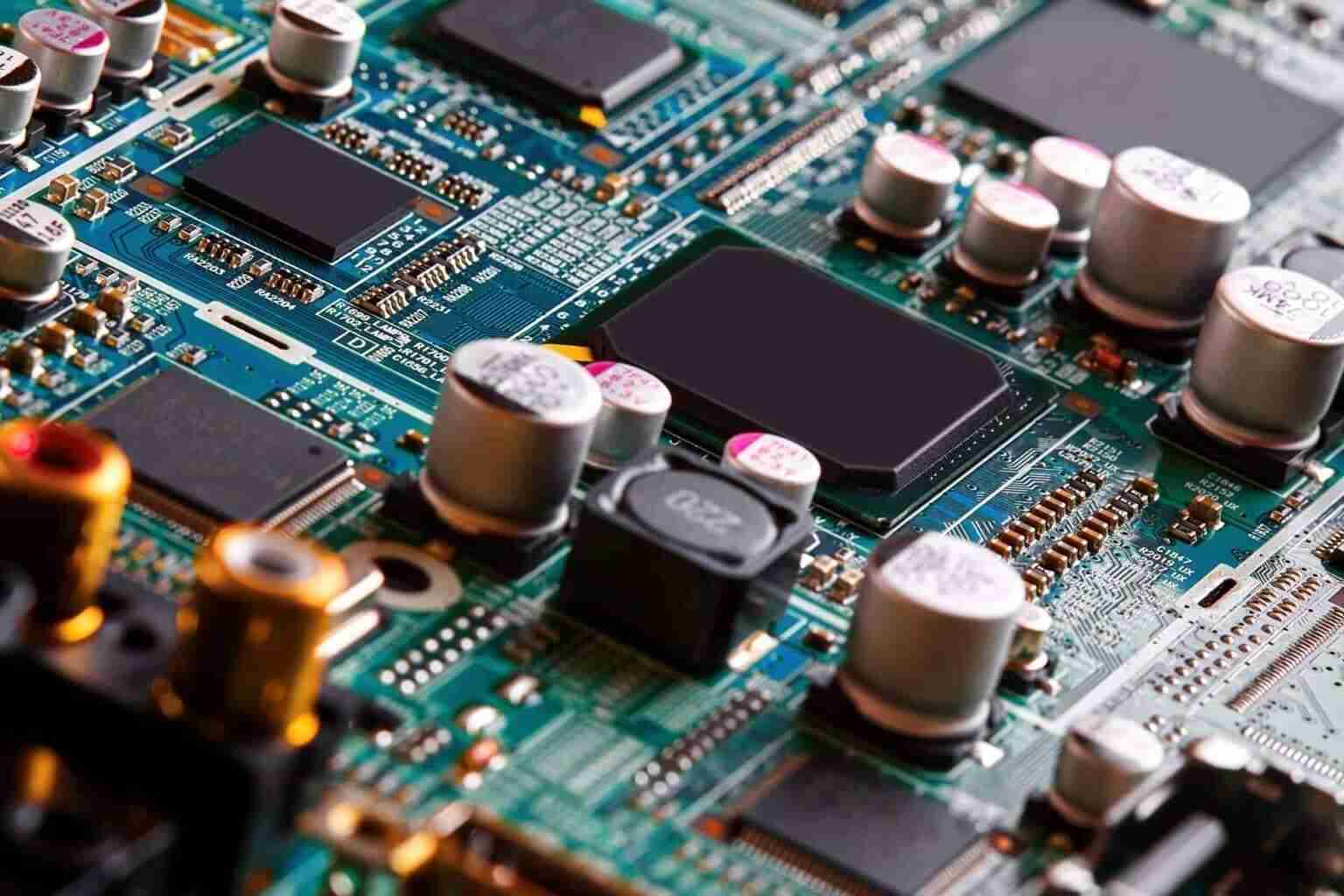

Today’s electronic gadgets are protected through the revolutionized technology of Printed Circuit Board. In addition to the ability to connect components the PCB‘s assembly is vital to protect against any potential dangers. This blog explains the reasons PCB assembly is crucial for protecting PCB electronic board and outlines the steps that guarantee the security and long-term durability of our electronic devices. Join us to unravel the most important aspects of protection for circuit boards.

The Importance of Circuit Board Protection

Threats Review to Circuit Board Protection

PCBs play crucial role in embedding the electronic components to protect from dangers without compromising their functionalities. Chemicals, dust, moisture and physical damage are among the most frequent culprits. Without adequate protection the risks could cause short circuits, corrosion and ultimately, the degrading on the board.

Impact of Environmental Factors on Circuit Board Integrity

The effects of environmental factors like temperatures, humidity, or exposure to corrosion-causing chemicals can greatly affect the efficiency as well as reliability of electronics. The creation of efficient protection measures is based on the particular environmental issues that every device will face.

Importance of Protecting Electronic Components

With the increasing complexity and expense associated with electronic equipment, making sure the safety for embedded devices is crucial. Protection of the circuit board not only assures immediate operation of the device, but also improves its reliability over time and reduces the need to replace the device frequently.

Strategies of PCB Assembly for Extra Protection

The Role of Surface Mount Technology (SMT)

To assemble PCBs, manufacturers use one of the most developed technologies, called Surface Mount Technology. Not only has this reduced dimensions for electronic devices but it has also strengthened resistance against external influences such as weather. SMT is now a norm in electronics of the present due to its efficacy and effectiveness.Assembling PCBs requires strategic planning and a highly sophisticated way to ensure effectiveness.

Conformal Coating and Its Benefits

An experienced electronic components distributor often suggests efficient ways to safeguard circuit boards is to apply conformal coatings. Conformal coatings made from materials like acrylic or silicone resin and polyurethane offer protection from chemicals, moisture and other substances in extreme environmental conditions such as automotive and aerospace industries.

Understanding the subtleties that come with coating PCBs is vital to develop a comprehensive strategy for protection. Different coatings offer different levels of protection. The process of application should be carefully planned to assure uniform coverage, without compromising the function and functionality of components.

Advantages and Disadvantages of PCB Assembly

Advantages:

• PCBs are able to withstand extreme temperatures and humidity, as well as other environmental variations, and be dependable in supporting the functioning for electronic parts. This is vital to ensure long-term reliability and stability for electronic devices.

• When compared to other circuit connections PCB circuit boards be more integrated and have a smaller designs. By putting circuit components directly onto the PCB, space will be reduced and overall performance increased. This is what makes PCB circuit boards an essential component of electronic devices of today.

• PCBs can be produced in mass quantities because the manufacturing procedure is standard. This means that regardless of the number of identical boards you require their performance and quality are guaranteed to be the same. Furthermore PCBs are simpler to alter and update should you require changing or improving the design.

• Because the PCB circuit boards built of top-quality materials and are protected by an extra layer of protection which is quite robust and simple to maintain? This is crucial to ensure the long-term stability and the reliability of electronic equipment and it also lowers the cost of repairs and replacement.

Disadvantages:

• PCB circuit boards come with the highest manufacturing costs in comparison to other circuit connections. This is due to the fact that the manufacturing of PCB circuit boards requires special equipment and technologies and rigorous quality controls. As technology advances production costs decrease and PCB circuit boards become more affordable and sustainable.

• The process of manufacturing PCB circuit boards is complicated and long-lasting PCB circuit boards are not appropriate for projects which require frequent design modifications as well as rapid repetitions. If you are looking for projects that require rapid response and flexibility alternative circuit connections could be more appropriate.

• The manufacturing and recycling processes for PCB circuit boards have an adverse environmental impact, including chemical emissions that may harm human health and the ecosystem if mishandled. Thankfully, with greater environmental awareness come measures designed to lessen this environmental burden for both manufacturers and producers.

Challenges in PCB Assembly and Protection

Common Issues Faced During the Assembly Process

Despite advancements in technology, difficulties remain with regards to challenges remain in the PCB construction process. The problem of soldering failure or component misplacement contamination is all common problems that could compromise the effectiveness of protection measures. In order to address these issues, you need the combination of cutting-edge technology as well as skilled workers and an effective quality control.

Strategies to Overcome Challenges and Ensure Protection

In order to ensure robust security of the circuit board, producers need to employ strategies to solve common challenges in assembly. This means investing in the latest manufacturing equipment, ensuring regular training for assembly staff and taking strict quality control procedures.

An accurate inspection and testing throughout the assembly process are crucial. The automated optic examination (AOI) and the X-ray examination will reveal the blights in soldering and insure correct positioning of factors. In addition, taking preventative measures, like making use of masks for soldering or precise styles of soldering, will ameliorate the overall trust ability for the entire assembly.

Conclusion

In the ever-changing world of electronic technology, understanding the significance in the PCB’s assembly for circuit board protection is essential. Modern assembly techniques, efficient PCB protective coatings and strict quality control all aid in the development of sturdy and robust electronic products. By prioritizing these aspects, can make sure that electronic component suppliers’ products are able to meet the requirements of a highly competitive market and deliver value for years for users.

Get Your PCB Quote!