How to Stop PCB Corrosion: Material Selection & Cleaning

PCB corrosion is a main cause of electronic product failure. As corrosion increases, the printed circuit board will work less efficiently or even stop working.

Get Your PCB Quote!

Table of Contents

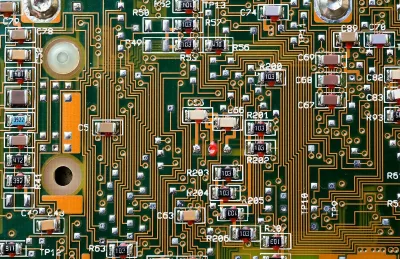

PCB corrosion is the metal erosion of printed circuit board due to environmental factors (such as moisture, pollutants, and electrolytes). This mainly damages copper foil circuits, solder joints, and substrates. It can lead to electrical performance degradation and even equipment failure. To protect it, you need to choose the right materials, improve the process, and control the environment.

1. Potential Factors of PCB Corrosion

The potential factors of PCB corrosion mainly include four categories: environment, chemistry, electricity and physics, as follows:

1.1 Environmental Factors

1) Moisture and Water

When the air is very humid (more than 65% moisture in the air), metal parts can rust faster. Moisture can also get into the inside of the PCB, which can damage the copper foil. When the air is more than 60% moisture, a conductive water film forms on the copper surface. This makes the electrochemical reactions happen faster.

Sulfur and chloride ions in salt spray or industrial waste gas in coastal areas react with copper to form copper sulfide/copper chloride, which significantly reduces conductivity.

2) Temperature Fluctuations

Changes in temperature cause materials to expand and contract, which can damage protective layers like solder mask. This increases the risk of corrosive media getting in.

1.2 Chemical Pollutants

1) Flux Residues

Rosin-based flux that is not cleaned after welding contains chloride ions (up to 500ppm). In a hot and humid environment, these chloride ions can form hydrochloric acid, which can corrode copper traces.

2) Ionic Contamination

The insulation resistance drops sharply when dust and chemical pollutants (such as NaCl) are introduced during manufacturing or storage. This happens when the surface ion contamination is greater than 1.56 μg/cm².

3) Acidic and Alkaline Substances Corrode Metals

Alkaline detergents (pH 9-11) increase copper foil’s resistance by 50%. On the other hand, acidic environments (pH 3) destroy the cross-linked structure of the resin, which causes insulation resistance to drop from 10¹¹Ω to 10⁸Ω.

4) Substrate Swelling

Kraft paper substrates absorb water and swell in alkaline solutions, which increases their thickness by 5%. This can cause short circuit risks.

1.3 Electrical and Electrochemical Mechanisms

1) Electrochemical Migration

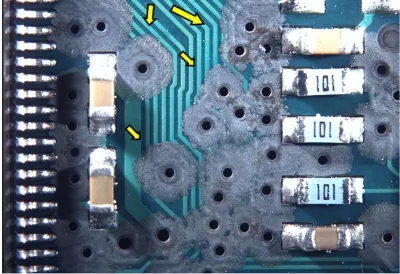

Voltage drives metal ion migration (such as the copper ion migration rate of about 0.1μm/h under 5V bias), forming dendrites in the presence of electrolytes (such as water films), leading to short circuits.

2) Galvanic Corrosion

When different metals touch each other (like copper and aluminum), a primary cell is formed in the electrolyte. The metal that’s more active (in this case, aluminum) acts as the anode, which speeds up the corrosion process.

1.4 Physical and Structural Defects

1) Fretting Corrosion

The vibration and friction at the metal contact point destroys the oxide layer and accelerates the penetration of electrolyte. For example, the corrosion rate of aluminum in copper-aluminum connection can be up to 3 times that of copper.

2) Inter-Granular Corrosion

The area at the grain boundary that is rich in impurities is easily corroded. This is common in gold-plated pads. The micropores in the nickel layer (>0.5μm) cause the underlying nickel to corrode preferentially. This causes solder joint failure.

3) Protective Layer Failure

Insufficient coverage of solder mask gaps or conformal coatings allows corrosion products to spread along the gaps (creeping corrosion).

2. How to Prevent PCB Corrosion?

Here are some general recommendations for preventing PCB corrosion. These recommendations cover key aspects such as design, manufacturing, storage, and maintenance.

| Corrosion Type | Mechanism & Trigger Conditions | Visual & Physical Features | Impact on Circuitry |

| Atmospheric | Exposure to high humidity (>60%) and industrial gases (S/Cl) | Green or black layers (verdigris) on copper surfaces | Reduced conductivity; increased electrical resistance |

| Pitting | Localized breakdown of protection or flux residues | Tiny holes, craters, or pits on the copper foil | Can lead to open circuits or impedance mismatches |

| Electrochemical Migration (ECM) | High humidity + DC voltage; causes dendrite growth | Tree-like or needle-like metallic crystal structures | Bridging between traces leading to intermittent shorts |

| Galvanic | Contact between two dissimilar metals in an electrolyte | Rapid erosion of the more active metal (e.g., Copper) | Solder joint degradation; structural connection failure |

2.1Preventive measures in the design phase

1) Optimize PCB Layout

Keep sensitive components away from corrosion-prone areas (such as edges), and ensure that the trace width and spacing meet specifications to reduce current density risks.

2) Substrate Selection

Use low-water absorption substrates such as PTFE high-frequency boards (water absorption is 90% lower than FR-4) to reduce the risk of moisture penetration.

The conductor layer should use metals that don’t rust, like gold or silver, to protect the base metals (copper or tin).

3) Surface Treatment Process

Applying the ENIG+OSP composite process (chemical nickel gold + organic solderability film), the salt spray resistance is increased to 96 hours.

The thickness of the solder mask is ≥15μm, covering the edge of the copper foil to form a “dam effect” and block the corrosion diffusion path.

The electroplating layer controls the nickel layer thickness to 4-6μm and the phosphorus content to 7-9wt% to prevent the bottom layer from corroding and lifting the gold layer.

4) Choose Corrosion-Resistant Materials

For example, they use copper alloy conductors and high-performance solder mask inks. They also apply conformal coatings (such as polyparaxylene) to keep out moisture and other contaminants. Conformal coatings are a type of protective coating that is very thin and doesn’t have any holes. It is made using a process called chemical vapor deposition (CVD), which is better than the old way of doing things.

| Protection Dimension | Technical Solutions | Key Parameters & Standards |

| Environmental Control | Deployment of dehumidification and monitoring systems | Maintain Relative Humidity (RH) below 60% |

| Surface Finishing | Use of oxidation-resistant coatings over bare copper | Recommended: ENIG (Electroless Nickel Immersion Gold) or ENEPIG |

| Conformal Coating | Complete encapsulation of PCB surface and joints | Use Modified Acrylic or PU; ensure 100% curing/dryness |

| Ionic Cleanliness | Rigorous cleaning processes before/after assembly | Must pass ROSE Testing (Residual Oxide Solvent Extraction) |

| Design Optimization | Increased trace spacing and optimized layout | Reduce electric field intensity to slow down ECM/Dendrite growth |

2.2 Manufacturing Process Control

Make sure you strictly manage the welding process, thoroughly remove flux residue, and prevent organic acids from causing crevice corrosion. Also, the circuit board needs to be manually cleaned after wave soldering.

Improve the electroplating process by controlling the solution’s composition, temperature, and duration. Ensure the thickness and quality of the coating, and clean and dry thoroughly.

Make sure you check the product thoroughly to find any problems early on.

2.3 Storage Environment Management

To prevent moisture condensation, keep the environment dry. Control the humidity at RH<30% and the temperature at 20-25℃. Use a dehumidifier or desiccant to help with this.

Avoid touching dust, salt spray, or chemicals. Use anti-static storage bags or sealed containers to keep out dust, salt spray, and chemicals. Dust and salt spray (which contain chloride ions) can speed up reactions involving metals. This means that these metals need to be protected in a specific way.

2.4 Maintenance and Care Strategies

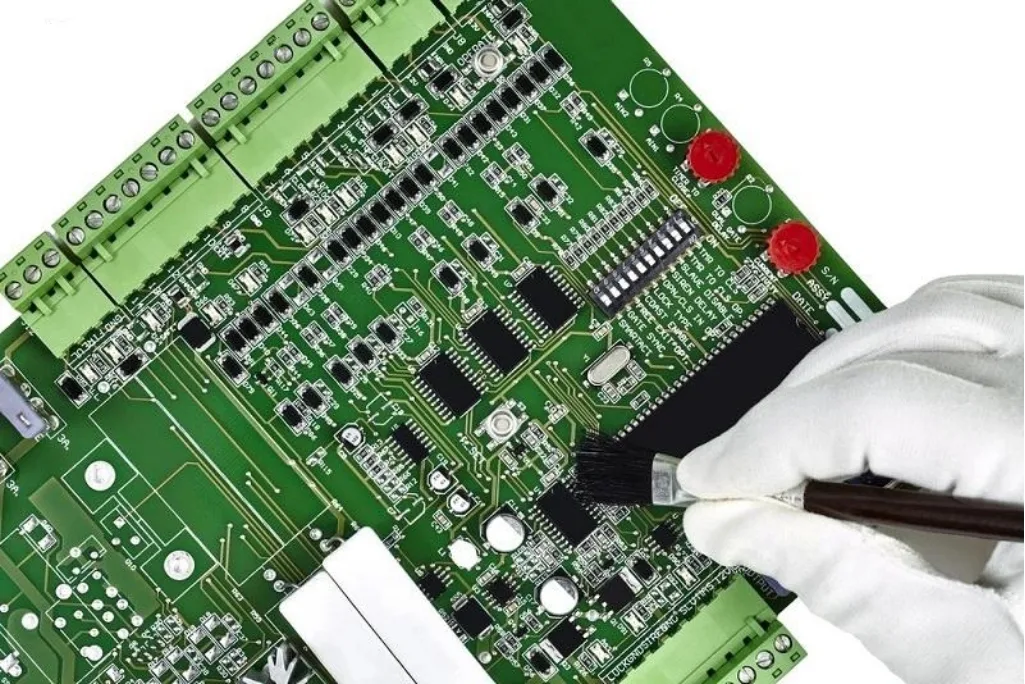

Clean the PCB regularly. For industrial equipment, clean it once a month. For consumer electronics, clean it once a quarter. Use a neutral detergent (pH 6.5-7.5) and a soft-bristled tool to gently brush the surface.

Keep an eye on the product’s condition. Check for corrosion by running it in an 85°C/85%RH environment for 1000 hours. This will help you evaluate the product’s performance. Also, make sure the product’s protective layer and solder joints are strong enough.

3. Methods for Detecting Whether PCB is Corroded

PCB corrosion detection requires a combination of appearance observation, electrical performance testing and microscopic analysis.

3.1 Appearance and Optical Inspection

1) Manual Visual Inspection and Magnifying Glass Observation

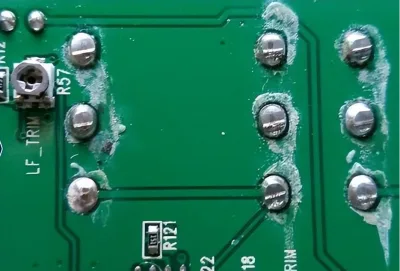

Focus on checking white crystals (electrolyte leakage) near the battery/capacitor, green copper rust on the connector pins, and black silver sulfide deposition around the solder joints. A magnifying glass (10x) can identify obvious corrosion marks.

2) Automatic Optical Inspection (AOI)

A high-resolution camera scans the PCB surface. The camera automatically identifies areas of circuit breakage, short circuits, and component corrosion. It compares these areas to a standard image. This standard image is suitable for rapid screening in mass production.

3.2 Electrical Performance Test

1) In-circuit Test (ICT)

Specialized probes contact the test points to accurately locate circuit open/short circuits and component failures caused by corrosion. The measurement accuracy is high and the fault location can be clearly identified.

2) Flying Probe Test

Flexible probes can detect how conductors are connected without needing fixed test points. This makes it good for figuring out what causes corrosion in small batches or on boards with a lot of components.

3) Surface Insulation Resistance (SIR) Test

Apply a DC voltage (e.g. 50V) in a high temperature and high humidity environment of 85°C/85%RH, and continuously monitor the resistance value. A sudden drop in resistance indicates electrochemical dendrite growth.

3.3 Special Corrosion Test

1) Ion Cleanliness Test

Solvent extraction of PCB surface residues, quantification of Na⁺, Cl⁻ plasma pollution concentrations by ion chromatography (standard: IPC-J-STD-001), and values exceeding the standard (such as Cl⁻>200ppm) indicate coastal/industrial corrosion risks.

2) CAF Accelerated Test

Design test boards with holes on opposite sides. Apply 100V bias and place them in a temperature and humidity cycle environment. Monitor insulation resistance changes to assess the risk of copper migration inside the laminate.

3) Salt Spray/Humid Heat Test

Simulate harsh environments (such as salt spray chambers) to verify the corrosion resistance and failure threshold of the PCB protective layer.

3.4 Microscopic Analysis Technology

1) X-ray Inspection (X-ray)

See through the inside of the multilayer board to identify solder joint cavities, plating peeling and hidden structural defects caused by corrosion.

2) Scanning Electron Microscopy and Energy Dispersive Analysis (SEM/EDX)

Look closely at the corrosion pits and the shape of the corrosion at 2000 times magnification to see if the corrosion has reached the coating.

EDX element analysis can identify the type of corrosion, like a sudden increase in sulfur content that could be from industrial waste gas corrosion.

4. How to Clean a Corroded PCB?

The corresponding method should be selected according to the degree of corrosion when dealing with a corroded PCB. The key points of operation are as follows:

4.1 Safety preparation

Power-off Protection: All power supplies must be disconnected and the battery must be removed before operation to prevent the risk of electric shock or short circuit.

Sensitive Component Removal: Take out the IC chips, capacitors, and other precision parts. Then, put them in a different place. This will help protect them from the cleaning fluid.

Corrosion Assessment: Distinguish the degree of corrosion (mild oxidation/solder point corrosion/circuit breakage) and deal with it in a targeted manner. Mild corrosion can be repaired, and severe corrosion requires replacement.

4.2 Cleaning and Rust Removal

1) Physical Cleaning

Use compressed air to remove surface debris and gently brush the corroded area with a soft brush (avoid damaging the components).

For stubborn corrosion, use fine sandpaper or a metal brush to lightly polish the metal contacts and remove the oxide layer.

2) Chemical Cleaning

Rinse with Deionized Water: Neutralize the residual electrolyte without leaving any water stains.

Baking Soda Solution: Mix with water and apply to the corroded area, neutralize the acidic residue and rinse it clean.

Special Board Washing Water/Isopropyl Alcohol: Dissolves flux and oxides, and has a significant effect on blackened or residual rosin.

Caustic Soda Water (use with caution with strong alkali): You need to use steam cleaning to get rid of that hard-to-clean flux. And you have to wear protective gloves when you’re using it.

4.3 Repair and Protection

Circuit Repair: Scrape off the green oil layer in the corroded area, and apply solder to cover the exposed copper wire to prevent more corrosion.

Drying Treatment: Dry thoroughly after cleaning, and can be baked in an oven at low temperature (only for minor corrosion without component damage).

4.4 Precautions

Ordinary Water is Prohibited: Tap water contains things that can easily cause secondary corrosion. Avoid strong corrosive agents. This includes strong acids and cleaning agents you don’t know about. They could damage the surface you’re working on.

Steam Cleaning Applicability: High-temperature steam can quickly remove flux residues, but the effect on severe corrosion is limited.

5. PCB Corrosion FAQs

Environmental Corrosion: Long-term exposure to oxygen and moisture causes oxidation reactions.

Electrochemical Migration: In a humid environment, metal ions can move and form dendrites. This can cause short circuits.

Material Defects: Small problems in the gold layer can cause the copper under it to come into contact with a corrosive substance. This can lead to local pitting.

Contaminant Residues: Contaminants such as flux and salts form electrolytes in a humid environment, accelerating corrosion.

Decrease in Mechanical Strength: Corrosion points weaken material continuity and affect structural stability.

Hidden Failure: Interlayer corrosion (such as CAF) of multilayer boards is invisible to the naked eye and may cause sudden failures.

Coating Protection: Spraying three-proof paint or polyparaxylene (Parylene) coating isolates moisture.

Optimize Design: Avoid dense wiring and reduce electrochemical migration caused by potential difference.

Strict Cleaning: Thoroughly remove ion residues (such as flux) after assembly.

Material Upgrade: Use corrosion-resistant substrates (such as ceramic substrates) and surface treatment processes.

Cleaning: Wipe the corroded area with isopropyl alcohol or special cleaner, and gently brush with a soft brush to remove oxides.

Remove Corrosion Layer: Grind the metal part with fine sandpaper until it is exposed (avoid damaging the circuit).

Neutralize Residue: Treat acidic corrosion residues with baking soda solution.

Drying: Thoroughly dry in a low-temperature oven (only for minor corrosion and no circuit damage).

Surface Insulation Resistance (SIR) Test: Monitor the resistance changes between conductors in high temperature and high humidity environments, and warn of dendrite growth.

Ionic Cleanliness Test: Quantify residual ion concentration (such as Na⁺, Cl⁻) by solvent extraction + ion chromatography.

CAF Accelerated Test: Create a simulation of a temperature and humidity cycle to detect how copper wire moves between layers.

Risk Points:

If there’s moisture or other contaminants (like flux) under the paint, it can cause problems like delamination or local corrosion.

Sudden temperature changes can cause the coating to crack. This can expose the metal circuit to an environment that can cause it to corrode.

Preventive Measures:

Before coating, make sure the surface of the substrate is clean and dry. This will ensure that it is free of any contaminants. After coating, it is essential to allow the coating to fully dry before turning on the power.

Select a tough conformal coating (such as modified acrylic) to adapt to temperature changes and mechanical stress.

White residue is often left-over flux that wasn’t cleaned properly, which can absorb moisture and lead to corrosion. Green residue (verdigris) is a sign that the copper has already reacted with moisture and oxygen (Atmospheric Corrosion), indicating active degradation of the circuit.

6. Summary

PCB corrosion is the “invisible killer” of electronic device failure. Unprotected printed circuit board (PCB) is susceptible to corrosion, and corrosion is the leading cause of PCB failure. Copper traces on a PCB can become less conductive when they corrode. In some cases, this can make the board malfunction or stop working altogether. Luckily, there are some common reasons for PCB corrosion, and fixing these problems can keep the PCB working well for its entire life.

Table of Contents

Get Your PCB Quote!