How Do You Perform Manual SMD Welding (SOIC)?

Get Your PCB Quote!

Table of Contents

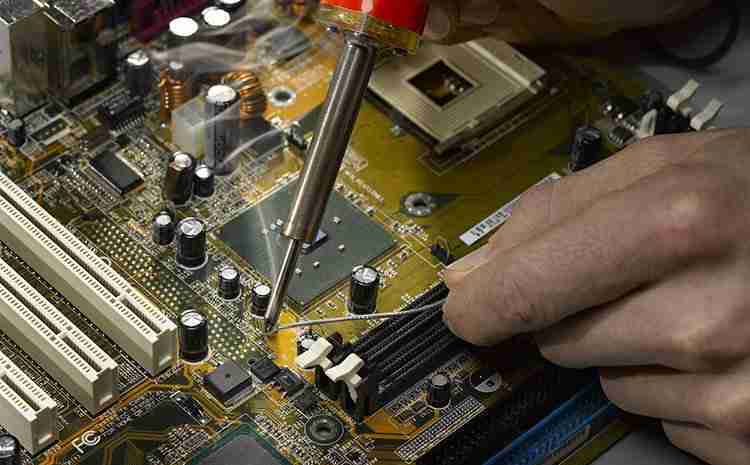

SMD IC Welding Techniques

1. You need to prepare a rectangular welding iron tip and make sure it is clean and free of dirt.

2. A welding station must be equipped to control the welding temperature.

Next, connect the SOIC integrated circuit (make sure it is aligned correctly) to a corner pad.

Then, apply welding to the opposite side of two, three, or more pins.

The key trick is: don’t try to connect all pins at once, it doesn’t matter.

Now, tilt the board to 45 or even 60 degrees so that gravity can flow the welding joints downward.

Next, use the welding tip to “pull” the welding joints downward.

The principle of this method is that the tension between the welding molecules is greater than the tension between the welding and the pad,

so the welding group will break from the “upper” pin.

The outcome is that you can consistently achieve high-quality welding results for all pins.

It can save a few seconds.

Hand welding – the connection does not look professional.

During welding operations, all connection points should remain consistent and equivalent.

Welding of gaskets is almost impossible to do by hand and usually takes several minutes. However, it can also be done in a short amount of time(I haven’t tried using a TSSOP IC on a factory PCB like a real professional circuit, but I’m happy with SOIC at the moment).

Currently, you can easily use SMD ICs without any special equipment, and their use is simpler than traditional ICs. All you need to do is stop thinking, “If I intentionally connect the IC pins with welding, it may cause damage.”

Typically, you don’t even need to use a dewelding wire.

Furthermore, a significant advantage of SMD IC is that it can be easily removed from the PCB when required, which is almost impossible with DIL IC, without causing damage.

Table of Contents

Get Your PCB Quote!