Prototype to Production: PCB Board Makers and Rapid Circuit Board Development

Explores rapid PCB prototyping to production, covering design, testing, and scaling with fast-turn PCB manufacturers for efficient product development.

Get Your PCB Quote!

Table of Contents

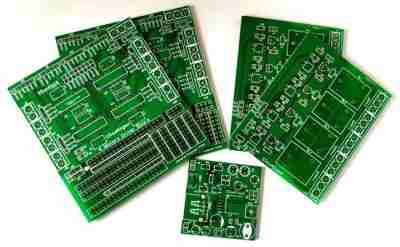

These days, everything is faster and more efficient, and so are the concepts of technology. Ideas that can quickly be turned into a product are often what drive innovation. All of the latest electronics begin on a printed-circuit board (PCB). Whether you’re making the next wearable tracker, a custom drone controller, or the next home device. The production of board from prototype depends on the speed and efficiency. PCB board makers and rapid development services are the answer.

What Is a Circuit Board Prototype?

Before anything goes into full production, engineers first build a working prototype. It’s the trial version of the final circuit board — a chance to test ideas, fix issues, and prove that everything functions the way it should. You have to test functionality, make sure all components are in the right place, and catch any design errors before you’ve even gone to mass production. A misplaced cap or a trace that’s too small could cause overheating or performance problems, or a complete failure. The circuit board prototype is a real-world test between the imagination and its implementation.

PCB Board Manufacturers

PCB board makers are expert who fabricates printed circuit boards. That’s why PCB manufacturers take care of the whole process from design layout to etching bobby tracks, applying solder masks, drilling holes, and installing factors. Selecting a supplier that combines speed with consistent quality makes all the difference to your project.

Some focus on large volume production, while others work in small runs with faster turnarounds. Many companies now offer both. This dual capability can be very valuable to startups and hardware developers that need to quickly iterate and scale once the design has been finalized.

From PCB prototype to final product: the process

So, let’s see how a simple idea becomes a working, manufactured board

- Design and Schematic Capture

A digital blueprint is the starting point for everything. Engineers design circuits and layout components using CAD software. The schematic shows the connections and how each element functions in relation to the larger system. At this stage, delicacy is crucial because any crimes will show up in the prototype.

- Prototype Fabrication

The PCB prototype is then made by a PCB board manufacturer. This process involves printing the circuit layout onto the board, typically made from fiberglass-reinforced epoxy laminate. Copper is used to form the conductive paths, and then the board receives a protective coat.

This is the stage where designers choose materials, layer count (for multi-layer board) and board thickness – all factors which influence performance and durability.

- Assembly and Testing

After fabrication, the components are mounted on the board by using surface-mounting technology (SMT), or through-hole assembly. The engineers then perform a series tests to verify performance. Is the voltage correct, for example? All components are working as expected? Does it have the capability to repel heat or electromagnetic interferences?

You run a series of tests to make sure the prototype is in line with the original design. This allows any flaws to be corrected prior to moving forward.

- Iterative Refinement

Rarely will the first prototype be perfect. Rapid development cycles are important for this reason. The layout is often tweaked, components are changed, and software is adjusted to optimize performance. A good PCB board makers offer flexible prototyping to accommodate these rapid changes.

- Transition to Production

After the prototype has met all performance and functional standards, production can begin. Scale is important here– production boards might need to be certified, have stronger quality control procedures, or suffer automated testing.

Working with a provider that can provide both prototyping and mass production means fewer handoffs and fewer delays, and better consistency.

Rapid PCB Development– Speed is Important

Rapid PCB prototyping is inestimable when it comes to snappily repeating hardware designs. These express results offer a variety of options for your urgent prototyping requirements, including same- day prototype PCBs and 24- hour turnarounds.

Quick- turn PCB Prototypes are a great way to verify your design and make adjustments on the spot. One step in the development process is to have a proof-of-concept beforehand. This allows you to test your circuit before investing in mass production.

In highly competitive markets such as consumer electronics and medical devices, the time to market can be a deciding factor in determining a product’s future. Rapid PCB development is a major game changer. Developers can now get boards within days, sometimes as little as 24 hours.

This speed allows faster innovation, quicker problem-solving and shorter development cycle. When paired with digital tools, this creates a feedback loop that is seamless between design, testing and iteration.

This agility is especially beneficial for startups. Instead of burning through capital on long development timelines they can validate concepts early, present working prototypes to investors and adapt to feedback from users on the fly.

Qualities to Identify in a PCB Supplier

You should ensure your PCB partner is experienced in handling long-term development project. The right board maker will influence your cost, speed, and quality.

Consider these things:

- Turnaround time: Are they able to deliver prototypes quickly

- ScalabilityCan they handle low-volume as well as high-volume productions?

- Quality Matters: Do they have industry certifications (ISO or IPC)

- Support for EngineeringCan they assist with design reviews or make suggestions regarding layout improvements?

- Material Choices:Do they’ve a wide range of board finishes and materials?

A provider who offers end- to- end services, from prototype through to full product, can reduce pitfalls and improve project execution.

Summary

PCBs play a vital part in modern electronics, from wearable technology and IoT detectors, to electric vehicles and robots. So, let’s get this thing moving. It’s a long road from concept to working device, but it doesn’t have to be with the right support.

It’s time to change your perception into the reality by launching your product into the market faster and effortlessly. Time, accuracy, and reliability are not privileges in a world where every second counts. They’re essentials.

Table of Contents

Get Your PCB Quote!