Understanding SMT Circuit Boards and Modern PCB Assembly Techniques

Exploring SMT technology's revolution in PCB assembly - enabling smaller, denser, and more reliable electronic devices through automated processes.

Get Your PCB Quote!

Table of Contents

From laptops and smartphones to household appliances, and even electric vehicles, everything is built on a tiny but strong foundation, the circuit board. In the past progress in technology like the assembled circuit board using the SMT technology and the advancements technology in the assembly of PCBs have transformed electronic devices made which has made them smaller efficient, reliable, and durable.

If you’re interested in the way these crucial components function or if you’re looking to gain an understanding of the latest manufacturing techniques This article explains the most important concepts in a simple and easy to understand manner.

What Is an SMT Circuit Board?

Let’s begin with the fundamentals. Surface Mount Technology also refers as SMT. As opposed to the older method that required components to be placed through holes on the boards, SMT permits components to be inserted directly on the board. This change in method has revolutionized the entire industry.

The SMT circuit board is basically a kind of printed circuit board (PCB) where the parts are directly soldered to the surface. They are generally smaller than those that were used in traditional through-hole technology and allow manufacturers to squeeze more functions into a smaller space.

This method offers several advantages:

- Small designwith smaller components and no need to drill holes. SMT boards could be significantly smaller.

- Greater density of componentsThe ability to put more components on a single board, thereby increasing its power and capabilities.

- Lower cost of productionMachines that are automated can position and solder components fast and precisely.

What Goes Into a PCB?

Before we get into the details of the way a PCB assembly functions, it’s essential to know what the printed circuit board is. A PCB is a small board constructed of insulating material, typically fiberglass – layered with copper tracks that permit electricity to flow between the components. The copper tracks replace wires that are traditional and allow you to build efficient and compact circuits.

The actual board typically contains:

- SubstrateThe base layer typically fiberglass or other non-conductive materials.

- Copper layerConductive pathways that create the electrical connections.

- Solder maskA protective layer that stops copper from oxidizing and also prevents accidental shorts.

- Silkscreenlabels and markings to aid with the placement of components and identify them.

Inside the PCB Assembly Process

PCB is the procedure of removing a basic circuit board and incorporating all the electronic components that create an operational unit. This involves using very specialized machines and knowledge to make sure everything is working as it should.

Let’s reveal some strategies or practices for assembling PCBs

- Soldering Paste Application

Solder paste is the first step of assembling onto the PCBs boards to place components. This is done with stencils to ensure that the paste goes only exactly where it is needed.

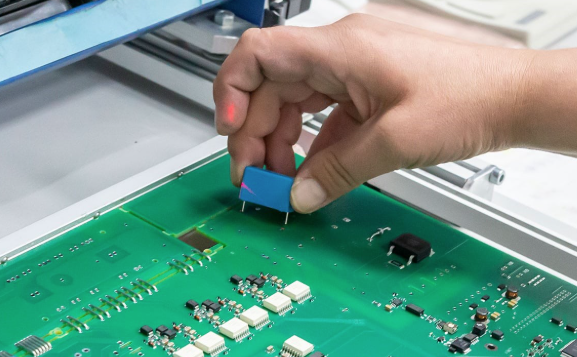

- Pick and Place

After the solder paste has been put set, the machines will pick up small electronic components and then place it precisely onto the boards. The machines operate at a blazing speed and can process thousands of electronic components in an hour.

- Reflow Soldering

After that, the board gets put through the reflow oven, in which it melts the solder paste, and creates solid connections between the parts and board. This step is essential to create strong and secure joints.

- Inspection and Quality Control

After soldering, boards will be inspected for imperfections. Automatic optical inspection (AOI) machines employ high-resolution cameras to look for missing or lost components, soldering issues and other issues.

- Testing

Depending on the sophistication of the item, the board can undergo a variety of testing, such as functional testing, in-circuit tests and x-ray inspections for concealed solder joints, which is especially suitable for high-density circuit boards that are assembled.

The Role of Assembled Circuit Boards in Modern Electronics

After a board has gone through these phases and passes the tests it’s referred to as a circuit board. It is the core of almost all electronic devices you’ll ever use. From controlling your smart TV’s power source to controlling the fuel injection for your automobile’s engine these boards execute all of the commands required and processing of data.

The move from bulky hand-soldered boards to sleek and machine-assembled boards makes today’s devices faster and more efficient, while also being loaded with options that were impossible to achieve just a few decades back.

How SMT Changed the Industry

The switch towards circuit board technology marked a pivotal point in the manufacturing of electronics. It not only allowed for the development of lighter and more robust devices and components, but it also enhanced the reliability of. With smaller mechanical connections and higher accuracy, SMT reduces the risk of manufacturing errors and extends the life of products.

Furthermore, SMT is extremely adaptable. Whatever it is or whether it’s a basic thermostat for your home or a more sophisticated Medical device, the SMT is able to be modified to meet the requirements of the specific application. This flexibility has led to the rapid progress have been observed in the field of industrial automation as well as consumer electronics, too.

Additionally, the advancement of AI as well as machine-learning is beginning to influence how boards are designed and tested prior to production.

Final Words!

Circuit boards and new assembly methods have contributed to the digital transformation that we see on a daily basis. These techniques enable engineers to incorporate more features into smaller sizes that result in more efficient and energy-efficient gadgets.

They’re not just for engineers anymore. The way boards work isn’t just for engineers anymore. Electronic devices are becoming more and more a part of our daily lives, a better appreciation of the tech that powers these devices helps us understand the intricate nature of our daily lives.

The next time you turn on your phone or adjust your thermostat, bear in mind that at the center of everything is a carefully built and carefully assembled device, an absolute masterpiece that represents the most advanced in engineering.

Table of Contents

Get Your PCB Quote!