Circuit Card Assembly vs. PCB Assembly: Understanding the Key Differences

Knowing the differences between PCB Assembly and circuit card assembly is essential for engineers, manufacturers, and buyers concerning electronic products.

Get Your PCB Quote!

Table of Contents

In the world of electronics manufacturing, the term circuit card assembly is often found alongside PCB assembly. There are stages or even different perspectives that either term may imply, being related or formerly used interchangeably. Knowing their difference is essential for engineers, manufacturers, and buyers concerning electronic products.

This article details those key differences between terms, their functions in the electronics domain, and the effects these have on the performance of devices. We will also elucidate on the overlapping part and why such nuances in terminology do matter.

1. What is Circuit Card Assembly?

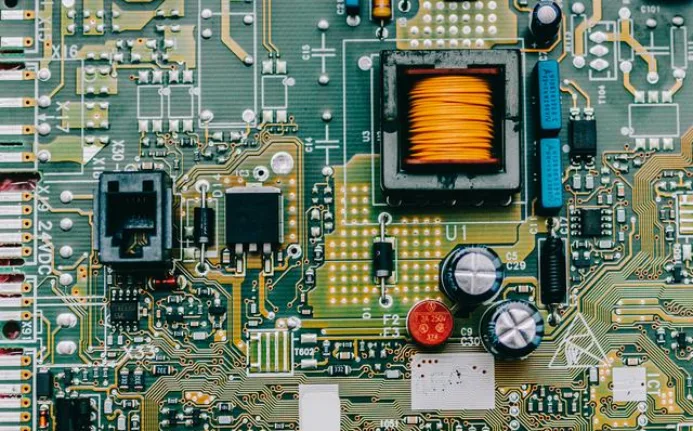

Most often abbreviated to CCA, it is a printed circuit board with all components mounted in place. This includes resistors, capacitors, and integrated circuits-a completely functioning entity meant to perform some tasks for a piece of equipment.

Unlike bare boards, which only mean printed substrates, a CCA is an operational unit that can be tested and installed into an electronic system.

When it is complete, it functions as a crucial part of the device’s internal system, carrying signals, providing power, and performing computations.

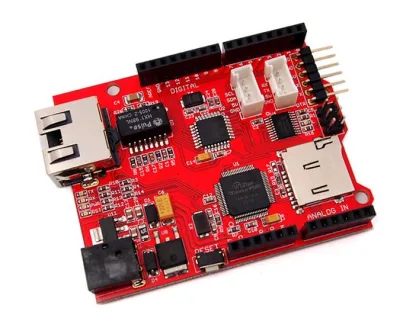

2. Defining PCB Assembly

The PCB Assembly involves placing electronic components onto a bare circuit board, either using surface-mount technology or the through-hole method. Once the components are soldered down to the board, it now works as a PCB. This might also be called a CCA in the industry, thus creating some confusion.

The goal of a printed circuit board assembly is to achieve physical and electrical connection between the board and the components therein. It is among the crucial processes in electronics manufacturing and could be automated to ensure reiteration.

3. Terminology: Why the Confusion Exists

The terminology, though, is quite varied from one industry to another. For instance, the aerospace and military sectors largely use the term circuit card assembly. Meanwhile, consumer electronics and commercial manufacturing tend to use PCB board assembly.

Hence, any verbal difference will not govern the type of work involved, yet it will lead to certain confusions. Keeping in mind where one term applies in an environment could go a long way in bridging the human interface hurdles in inter-departmental or inter-vendor dealings.

Even though both describe an assembled board, using the correct term helps clarify the stage of development and the level of completeness.

4. Differences in Application

There must be a final difference in the image of the product when viewed by a customer. CCA will in many cases imply a production-ready board, inspected and approved. It is not merely a handful of components; it is fully certified hardware.

PCB Assembly often is considered to be the procedure of installing the parts on the board. It might or might not include functional testing or final quality assurance.

In some fields, it is considered to be an umbrella term. CCA is the final tested module, PCB assembly is just one step towards that.

5. Role in Modern Electronics

In the realm of design of smartphones, building drones, and manufacturing industrial equipment, both PCB assembly and CCA shared a common role in the lifecycle. Poor assembly equals either poor performance of a gifted device or its total demise.

Each layer of the circuit, every trace, and component must be aligned perfectly. Negligence in any one of the processes could lead to faults which may almost never be detected but will be darn easy to replicate in a multitude of units.

6. Inspection and Testing Procedures

Testing and Quality assurance are more often associated with a Circuit Card Assembly. While PCB assembly is finished once the parts are placed and soldered, a CCA goes one step further and is tested for function and sometime inspected for defects.

At the testing phase, it is made certain that the board will perform in the final product. Software simulation, live current tests, environmental stress tests, etc., are involved.

In any application where reliability is an absolute must-do, such as medical devices or aerospace tech, the extra steps really do count.

7. Standards and Compliance

Different standards are applied for PCB assembly and for CCAs according to the market. Since these are quality benchmarks, the IPC standards are generally accepted.

Usually, for military or aviation-related components, other certifications and tests are involved, e.g., temperature resistance, shock resistance, and life testing.

8. The Understanding of the Manufacturing Flow

Usually, manufacturing begins with PCB fabrication. This includes layering copper, track creation, and board preparing. The PCB assembly begins with the placement and soldering of components right after fabrication.

Upon the completion of all these operations, the unit is submitted to the final inspection and testing. If deemed successful in every test, its status will be completely elevated into that of a CCA.

Every one of these steps must have a faultless preceding step. That’s why manufacturers often use integrated systems and traceability tools to track every part and step.

9. Benefits of Knowing the Difference

The logistics of procurement and development at times can be blocked if such terminologies are confused. For instance, specific delays could occur if a team asks for PCB assembly when in fact a fully finished, tested board is desired.

Furthermore, it helps to emphasize the budget, which could differ if the nature of the work is clear: for instance, a circuit card assembly usually lists at a higher price because it includes testing and inspection from start to finish. Designating it incorrectly as a simple PCB assembly could result in an underrated cost.

On the other hand, using proper terminology helps ensure smooth communications with partners and vendors during technical convos.

10. Summary

While both terms imply work assembly of components onto circuit boards, the difference certainly does matter. A circuit card assembly is a finished, tested unit ready for deployment. PCB assembly, though an important step, is just one of the intermediate steps in this journey.

By knowing the difference, electronics professionals can better plan, execute, and deliver industry expectations in their products. From mobile gadgets to advanced aerospace tools, every little detail counts, starting from the language we use.

These terms therefore don’t just help with manufacturing. More clarity is given to the project, correct costing, and product performance. During this stage, where time-to-market and quality are everything, that understanding becomes a treasure.

Table of Contents

Get Your PCB Quote!