Low-Volume PCB Assembly: From Prototype to Production

Low-volume PCB assembly is a crucial link connecting R&D and mass production in electronics manufacturing, and is very suitable for startups and new products.

Get Your PCB Quote!

Table of Contents

- 1. តើសន្និបាត PCB កម្រិតសំឡេងទាបគឺជាអ្វី?

- 2. តើអ្វីជាគុណសម្បត្តិនៃសន្និបាត PCB កម្រិតសំឡេងទាប?

- 3. ដំណើរការទាំងមូលនៃសន្និបាត PCB កម្រិតសំឡេងទាប

- 4. បញ្ហាប្រឈម និងដំណោះស្រាយនៅក្នុងសភា PCB កម្រិតសំឡេងទាប

- 5. ទស្សនវិស័យឧស្សាហកម្មសម្រាប់ Lអូ-VOlume PCB Assembly

- 6. សំណួរគេសួរញឹកញាប់អំពីសភា PCB កម្រិតសំឡេងទាប

- 7 ។ សេចក្តីសង្ខេប

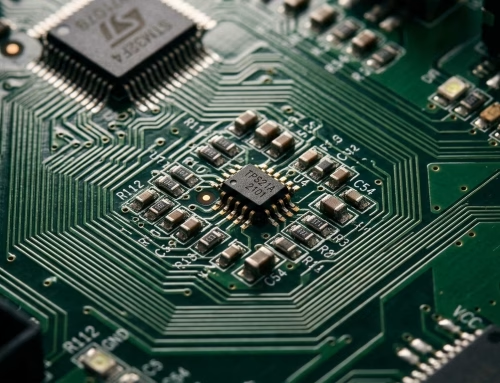

At the heart of modern electronic devices, printed circuit boards (PCBs) play a vital role. They serve not only as the physical platform supporting electronic components but also as the highway for electrical current flow, ensuring efficient and accurate signal transmission between various parts. For innovators, engineers, and small businesses, low-volume PCB assembly has become the go-to solution for rapid design validation, prototyping, and even initial market testing. This article will detail the manufacturing methods, challenges, and solutions for low-volume circuit board fabrication.

1. What is Low-Volume PCB Assembly?

Low-volume PCB assembly refers to end-to-end services—from design optimization and component procurement to production assembly and testing/delivery—tailored for circuit board assembly needs involving smaller order volumes (typically dozens to thousands of units) and diverse product types. Its core characteristics include high flexibility, enabling adaptation to R&D pilot production and customized requirements while supporting rapid design iterations.

Order Quantity Range: Low-volume PCB assembly orders typically involve quantities under 5,000 pieces, with some manufacturers offering assembly services as low as a single piece.

Primary Purpose: Primarily used for testing and validating PCB projects and designs, helping engineers identify and correct issues in designs or components before mass production.

Service Scope: Includes comprehensive PCB assembly testing, Design for Manufacturability (DFM) and Design for Testability (DFT) services. Some manufacturers also offer engineering document review and Bill of Materials (BOM) procurement services.

Please note that manufacturers usually start with low-volume production before moving on to large-scale manufacturing. This allows them to thoroughly test and validate product designs. Low-volume production is also suitable for users who do not intend to produce thousands of PCB assemblies.

Customized hand-assembly services are only feasible for low-volume production and require close collaboration with the customer. This flexibility is best suited for startups, companies launching new products, small-scale applications, short-cycle projects, and specialized industrial equipment manufacturers.

2. What are the Advantages of Low-Volume PCB Assembly?

Low-volume PCB assembly offers significant advantages in flexibility, cost control, process adaptability, and rapid iteration, making it an efficient choice for transitioning electronic products from R&D to mass production.

1) Flexibility and Rapid Response

Low-volume assembly swiftly adapts to market shifts, supporting new product development and trial production. Customers can flexibly adjust designs based on feedback. This flexibility shortens the time-to-market cycle, helping capture market opportunities. Standard turnaround times range from 3 to 7 days (expedited options available in 24-72 hours), meeting rapid iteration demands.

2) Reducing Capital Pressure

Compared to mass production, low-volume assembly requires a lower initial investment, which reduces inventory pressure and the amount of capital tied up. This makes it ideal for SMEs and start-ups. For example, minimum PCB orders start as low as 5–500 pieces, avoiding excessive stockpiling. This makes it perfect for R&D prototyping, initial production runs, or small-to-medium batch orders.

3) Supporting for Complex Processes & Customization

Low-volume assembly handles components challenging for automated placement (e.g., large, irregularly shaped, or heat-sensitive parts) and enhances soldering quality through post-soldering processes. It also supports hybrid techniques (e.g., combining SMT and THT) and personalized customization.

4) Low-Cost Trial and Iteration

Low-volume production facilitates design validation and modifications, reducing trial-and-error costs and development risks. For instance, low-volume assembly enables rapid identification and correction of design flaws, preventing rework losses after mass production.

5) Adaptability to Diverse Design Requirements

Low-volume assembly accommodates high-density designs (e.g., via/blind via technology), enhancing signal transmission performance while reducing electromagnetic interference. Furthermore, it meets the stringent reliability demands of sectors like medical devices and prototyping.

3. Entire Process of Low-Volume PCB Assembly

1) Design and Preparation Phase

Design Software Selection

Everything begins with precise design. Common PCB design software includes Altium Designer, Eagle, KiCad, etc., offering comprehensive solutions from schematic design to routing and layout. Select appropriate software to draw circuit schematics and perform PCB layout and routing based on project requirements.

Design Rule Checking (DRC)

After completing the initial design, utilize the software’s built-in DRC functionality to verify compliance with manufacturing requirements. This includes verifying minimum line widths, spacing, drill hole dimensions, and ensuring overall manufacturability. This step is critical for preventing issues during later production stages.

2) File Output and Optimization

Gerber File Generation

Gerber files are the industry-standard format for PCB manufacturing data, containing detailed information for each layer of the circuit board. Ensure a complete Gerber file package is generated, including top layer, bottom layer, solder mask layer, silkscreen layer, etc., along with drill data and assembly drawings.

File Review and Optimization

Before submitting for production, meticulously review the Gerber files to avoid design errors. Simultaneously, consider appropriate design optimizations, such as adding test points or refining trace routing to minimize interference, thereby enhancing the circuit board’s performance and testability.

3) Selecting Manufacturers and Placing Orders

Manufacturer Evaluation

Choosing a reputable and experienced PCB manufacturer is crucial. Evaluate factors such as processing capabilities (e.g., layer count, materials, specialized processes), lead times, pricing, and customer service. Key Selection Criteria:

Certification Standards: Prioritize manufacturers with certifications like ISO9001, UL, and RoHS to ensure quality and reliability.

Process Capabilities: Supports complex designs like high precision (e.g., minimum line width/spacing of 0.1mm), blind/buried vias, and impedance control.

Order Placement and Communication

Upload Gerber files to the manufacturer’s platform, specifying board material (e.g., FR-4), surface finish (e.g., gold plating, solder mask), quantity, and any special requirements. Maintain clear communication with the manufacturer to confirm all details are accurate.

4) Manufacturing Process

Material Preparation and Cutting

Select appropriate substrate materials based on order requirements and cut them to size, preparing for subsequent processes. Ensure selected materials meet design specifications and quality standards.

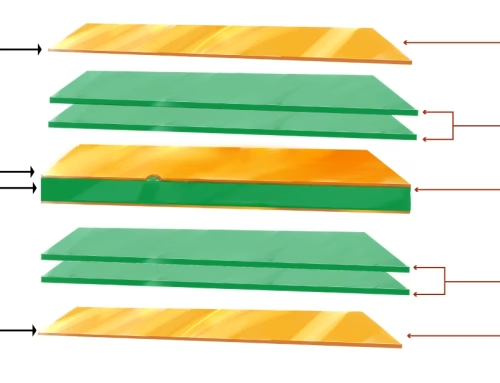

Copper Foil Layer Processing

Transfer design patterns onto the copper foil layer via photolithography or direct imaging techniques. Excess copper is then removed through etching, leaving the required circuit traces. This step determines circuit precision and integrity.

Hole Drilling and Interconnection

Drill holes in the circuit board, creating through-holes or blind/buried vias as specified. Ensure hole wall conductivity through processes like electroplating or electroless nickel-gold plating. This step establishes electrical connections between layers.

Surface Treatment

Surface finishes are applied per design specifications—such as OSP (Organic Solderability Preservative), HASL (Hot Air Solder Leveling), or ENIG (Electroless Nickel Immersion Gold)—to protect the board and enhance solderability. This step is critical for durability and soldering performance.

Solder Mask and Silkscreen

Solder mask ink is applied to shield circuits from environmental exposure, while silk screen printing adds identification markings and component placement guides. This step ensures the PCB’s maintainability and operability.

5) Quality Inspection and Delivery

Inspection and Testing

Each PCB undergoes comprehensive quality checks using methods such as AOI (Automated Optical Inspection) and flying probe testing to ensure electrical performance and appearance meet standards. Rigorous quality inspection is key to guaranteeing the final product’s quality.

Packaging and Shipping

After passing rigorous quality screening, circuit boards are meticulously packaged to prevent damage during transit and shipped to customers according to agreed-upon schedules. This ensures products arrive intact.

4. Challenges and Solutions in Low-Volume PCB Assembly

Low-volume PCB assembly indeed faces unique production challenges, but these issues can be effectively addressed through targeted strategies and advanced technical approaches.

4.1 Key Challenges of Low-volume PCBA

1) Cost Control Difficulties

Low-volume production cannot leverage economies of scale to reduce fixed costs such as tooling fees and equipment setup charges, resulting in higher unit costs. Additionally, smaller raw material purchase volumes make it difficult to secure favorable pricing.

2) High Process Complexity

Small-batch orders often involve multiple specialized process requirements (e.g., blind/buried vias, high-frequency/high-speed circuits, rigid-flex combinations), demanding highly specialized equipment and skilled technicians. Frequent process changes also increase management complexity.

3) Difficulties in Controlling Production Lead Times

Low-volume PCB assembly orders usually have tight deadlines, but special processes, equipment debugging, and raw material procurement can all cause production delays. If quality issues arise requiring rework, delivery schedules are further impacted.

4) Quality Assurance Challenges

Despite lower production volumes, customer quality expectations remain unchanged. Low-volume production involves multiple batches and frequent line changes, making consistent quality difficult to guarantee. Traditional sampling inspection methods may fail to detect all potential issues.

5) Challenges in Assembling Ultra-Small Components and Flexible PCBs

For products like wearables, mounting 01005/0201 ultra-small components often leads to misalignment or missing parts. Flexible PCB soldering is also prone to circuit breaks due to high-temperature deformation and stress concentration.

4.2 Solutions

1) Optimize Cost Management

Consolidate low-volume orders for centralized procurement and establish long-term partnerships with suppliers to secure preferential pricing.

Allocate mold costs across subsequent orders or negotiate preferential terms for mold expenses.

Introduce automated equipment to enhance production efficiency and reduce labor costs.

2) Enhance Process Precision

Employ dual-camera + 3D vision placement machines to achieve ultra-small component positioning accuracy of ±0.005mm.

Set tiered placement pressure based on component type and use flexible nozzles to prevent component crushing.

Utilize electroformed stencils and ultra-fine-particle solder paste to ensure uniform paste printing.

3) Strengthen Production Management

Implemented an intelligent manufacturing operations management system for comprehensive process control and equipment coordination across all stages.

Optimized production scheduling through digital systems to accelerate changeover efficiency.

Established a full-process traceability system for rapid root cause analysis of quality issues.

4) Specialized Flexible PCB Processing

Employed low-temperature soldering techniques, limiting peak reflow temperatures below 200°C.

Secure flexible PCBs with specialized fixtures to prevent positional shifts during soldering.

Select substrates and components with matched thermal expansion coefficients to minimize soldering stresses.

Through these measures, we can ensure the quality of low-volume PCB assembly while effectively controlling costs and shortening production cycles, meeting diverse customer demands.

5. Industry Outlook for Low-Volume PCB Assembly

As a vital link in the electronics manufacturing supply chain, the industry outlook for small-batch PCB assembly is closely tied to the overall trends in the PCB market.

Sustained Growth in Market Demand

Low-volume PCB assembly primarily serves product R&D, pilot production, and customized requirements. With the rapid development of emerging fields such as AI, new energy vehicles, and 5G, demand for high-performance, customized PCBs has significantly increased. For instance, a single PCB in an AI server can be worth 5-7 times that of a traditional server, while the PCB value per new energy vehicle exceeds $300. The demand for high-end products like High-Density Interconnect (HDI) boards and high-frequency/high-speed boards in these sectors directly expands the market space for small-batch orders.

Technological Upgrades Drive Industry Transformation

The PCB industry is evolving toward higher precision, greater integration, and thinner profiles. Small-batch orders, characterized by “small volumes, diversity, and fast delivery,” require enterprises to possess flexible production and rapid response capabilities. Looking ahead, as 18-layer and higher multi-layer board technologies become widespread, AI server PCB line width standards drop below 20 microns, and green manufacturing technologies become standard, low-volume assembly enterprises must simultaneously enhance their technical capabilities to adapt to this high-end trend.

Future Trends

- Product Premiumization: Low-volume assembly orders will increasingly involve high-end products like HDI and packaging substrates.

- Service Differentiation: Companies must build competitiveness through technical specialization and market differentiation.

- Regional Clustering: Supply chain collaboration centered around leading end-user manufacturers will intensify.

6. Low-Volume PCB Assembly FAQs

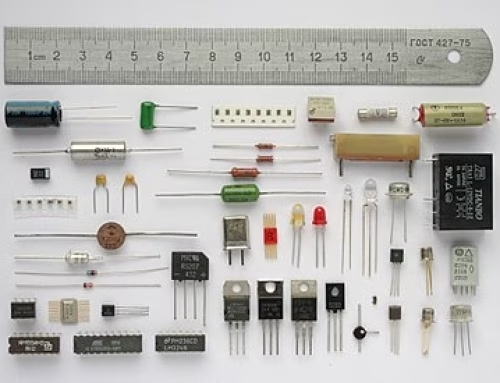

PCB assembly service involves mounting electronic components (such as resistors, capacitors, chips, etc.) onto printed circuit boards (PCBs), primarily using surface mount technology (SMT) and through-hole technology (THT). Low-volume assembly services typically include the following processes:

Design Phase: Provide Gerber files, BOM (Bill of Materials), and placement files.

PCB Fabrication & Component Procurement: PCB manufacturing and component sourcing.

Assembly & Testing: SMT placement, soldering, functional testing, etc.

Delivery: Shipment of finished or semi-finished products.

Required Documents: Gerber files, BOM list, placement files (e.g., pinout diagrams).

Recommended Documents: Assembly instructions or sample photos to prevent component placement errors.

Component Spacing: Maintain sufficient clearance to avoid assembly difficulties or rework issues.

Board Edge Clearance: Maintain sufficient space between components and board edges to prevent collision with placement machines.

BOM-package Matching: Ensure component part numbers in the BOM match PCB packages. For example, through-hole diodes must not be mistakenly used in surface-mount packages.

Ensure the service provider typically sources components through authorized channels;

Provide quality control measures like X-ray inspection (e.g., for BGA soldering) and AOI optical inspection.

Reduce unnecessary component types and adopt standardized design modules to lower production complexity.

Select contract manufacturers with procurement capabilities to centrally manage BOMs, mitigating customer self-procurement risks and identifying stockout risks early through DFM (Design for Manufacturability) reviews.

Utilize automated placement machines, AOI inspection, and other equipment to enhance efficiency and minimize human error.

Assessing a PCB assembly provider’s capacity requires comprehensive consideration across multiple dimensions, including equipment capabilities, production scale, management efficiency, and supply chain stability.

7. Summary

Low-volume PCB assembly serves as a critical link between R&D and mass production in electronics manufacturing, particularly suited for personalized needs requiring rapid validation and flexible adjustments. As electronic products evolve toward greater intelligence, digitization, and connectivity, the entire manufacturing supply chain faces overwhelming demand for diverse emerging electronic components. From the perspective of PCB order volumes and customer requirements, low-volume boards hold significant importance within the PCB industry.

Table of Contents

- 1. តើសន្និបាត PCB កម្រិតសំឡេងទាបគឺជាអ្វី?

- 2. តើអ្វីជាគុណសម្បត្តិនៃសន្និបាត PCB កម្រិតសំឡេងទាប?

- 3. ដំណើរការទាំងមូលនៃសន្និបាត PCB កម្រិតសំឡេងទាប

- 4. បញ្ហាប្រឈម និងដំណោះស្រាយនៅក្នុងសភា PCB កម្រិតសំឡេងទាប

- 5. ទស្សនវិស័យឧស្សាហកម្មសម្រាប់ Lអូ-VOlume PCB Assembly

- 6. សំណួរគេសួរញឹកញាប់អំពីសភា PCB កម្រិតសំឡេងទាប

- 7 ។ សេចក្តីសង្ខេប

Get Your PCB Quote!