The Complete Guide to Printed Circuit Board Assembly (PCBA)

From components selection to culminating testing, understanding Printed Circuit Board Assembly is helpful to people involved in electronics production.

Get Your PCB Quote!

Table of Contents

Printed Circuit Board Assembly has entered modern electronics manufacturing as one aspect of the utmost importance. It entails attaching components to the printed circuit board to assemble a working electronic device. Without such processes, the digital world we so heavily lean upon wouldn’t function.

Understanding the very basics of assembling these boards should prove helpful for an engineer, a company, and anybody else involved in electronics production. From surface-mount technology to inspection methods, the present text aims at boasting a simple, straightforward guide to the whole process.

1. What Is Printed Circuit Board Assembly?

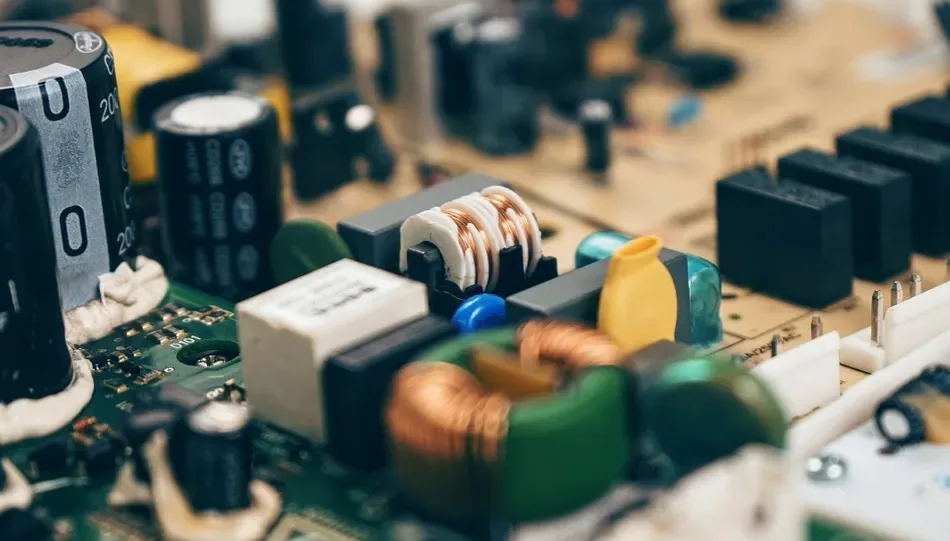

Printed circuit board assembly (PCBA) refers to the stage at which electronic components are soldered or otherwise attached to a bare PCB to form a working electronic circuit. PCBA allows your computer, phone, or any other smart device to work. Assembly of printed circuit boards requires a precise component placement and soldering process to render possible optimal functionality.

First, the design and fabrication of the PCB start. As the board is finally ready, it goes to assembly, where all components are mounted. Each step must be precise since a minor error would result in a failure or diminished performance.

2. Components of the PCBA Process

The PCBA process can vary according to application and type of PCB, but several steps are commonly found in all processes. Applying solder paste is usually the first step of the process and is dispensed onto the board through a stencil. The paste acts as a binder that temporarily holds down the components.

The next operation is pick-and-place, which entails the fact that the components are put on the board by automated machines. Surface-mount devices are carefully positioned on their respective locations. This is followed by reflow soldering, where the solder is melted and secures the parts onto the board.

The through-hole soldering process is different. These components are inserted into holes on the board to be soldered, usually using wave soldering or manual soldering techniques depending on volume or complexity.

3. Quality Control in PCBA

Every PCB assembly should meet strict quality standards, hence carrying out testing and inspection assumes utmost importance in the process. Post-assemblies, the boards are inspected visually either by manual means or by AOI system, which catches errors like misalignment of components, faulty soldering, or missing components.

More elaborate testing also includes X-ray inspections for complex boards, especially those that have hidden solder joints. Functional testing is then performed to check if the board functions perfectly fine in reality.

Striving to maintain quality helps keep rework costs down and improves product reliability. For companies making consumer electronics, medical devices, or aerospace systems, the consequences of failure could be huge. That’s all assembly reliability comes down to.

4. Types of Assembly Methods

The two main types of PCBA are surface-mount technology and through-hole technology. Nowadays, SMT is more common because it is quicker to set up and tends to save in space. It is easier for manufacturers to place miniature components on both the sides of the board.

Through-hole, on the other hand, offers a stronger mechanical bond and is still considered for applications demanding such durability, like automotive, or military product lines for that matter. For modern electronics, however, a PCBA circuit board is crucial for consistent and dependable performance.

Hybrid assembly is an emerging field, combining the two technologies, SMT and THT, to give more design freedom and the ability to build boards that can be joined with performance and vigor.

5. Materials Used in PCBA

It needs good-quality materials for correct operation. Its board’s base material is usually fiberglass (FR4), which provides insulation and strength. Its copper forms the conducting paths to join the circuit’s different elements.

Solder paste, a mixture of metals and flux, makes the formation of electrical or mechanical connections possible. Due to environmental laws, it is lead-free solder as the norm in many countries.

Depending on function, there are very wide varieties of component materials, such as resistors, capacitors, integrated circuits, microcontrollers, etc. Each material must be selected based on temperature resistance, conductivity, and compatibility with other parts.

6. Practical Applications of PCBA Interfaces

PC Board Assembly finds usage in endless numbers of industries. It powers consumer electronics such as laptops, mobile phones, and televisions. On the automotive side, everything from engine control units to ADAS systems is PCBA-driven.

Medical equipment requires extremely precise assembly of PCBs to guarantee their proper functioning. From heart monitors all the way down to portable ultrasound machines, they all depend upon correctly assembled boards.

The PCBA is also critical to industrial automation, aerospace, and telecommunications. They, along with some other CNC applications, call for the highest reliability, often in very unfriendly environments, thereby forcing their manufacturers to abide by the most stringent assembly standards.

7. Importance of Design for Assembly

The assembly process begins with design. Engineers have to produce board layouts that ease production and minimize the risk of error. This includes component placement and trace routing and spacing that enable efficient machine work.

The procedures are there to decrease production costs and lead time. Boards designed for such procedures easily facilitate manufacturing, testing, and repairing processes.

Including clear labels, proper spacing, and test points can also simplify inspection and quality control. In the long run, good design saves money and improves product lifespan.

8. How to Choose an Assembly Partner

A deciding moment would be the actual selection of an assembly partner for product development. One must consider providers that have industry experience, strong quality control systems, and that can deal with a job on the scale of the one you have.

Chosen partners must also be big on the turnaround time, communication, and after sale support on assembly. Turnkey solutions are more and more being offered these days, which basically go from sourcing of components to testing.

The right partner doesn’t simply make your boards; they help nurture your ideas into reality.

9. Summary

An understanding of the Printed Circuit Board Assembly processes is going to immensely help anyone working with electronics for purposes of making smarter choices. From components selection to culminating testing, all go a long way toward enhancing performance and reliability.

With the increasing demand towards everything getting smarter, smaller, and faster, there is probably going to be an increase in demand for efficient high-quality PCBA. For any engineer, entrepreneur, or even a techie, knowing how these critical boards get built gives you an edge in the modern world.

Table of Contents

Get Your PCB Quote!