14+

Years Experience

98.15%

On-Time Delivery

96%

customer satisfaction rate

99%

Quality Pass Rate

What are the Advantages and Disadvantages of 3D Printing?

Why Choose Us as Your 3D Printing Service Provider?

With advanced CNC machining, 3D printing, silicone molding, rapid molding and injection molding, sheet metal processing, and various surface treatment technologies, we combine multiple processes and provide one-stop prototype and product processing services.

As your most reliable 3D printing service provider, you’ll always receive fast quotations and real-time tracking of order status from our highly skilled team.

Not only are we ISO 9001, ISO 14001, IATF 16949, and ISO 27001 certified, but we also have a comprehensive quality control system. It’s our goal to be your go-to 3D printing company by consistently exceeding your expectations in regarding customer service, product quality, and price.

Contact us today for a tailor-made quote or consultation. We’re looking forward to collaborating with you on your next project!

Popular 3D Printing Technologies

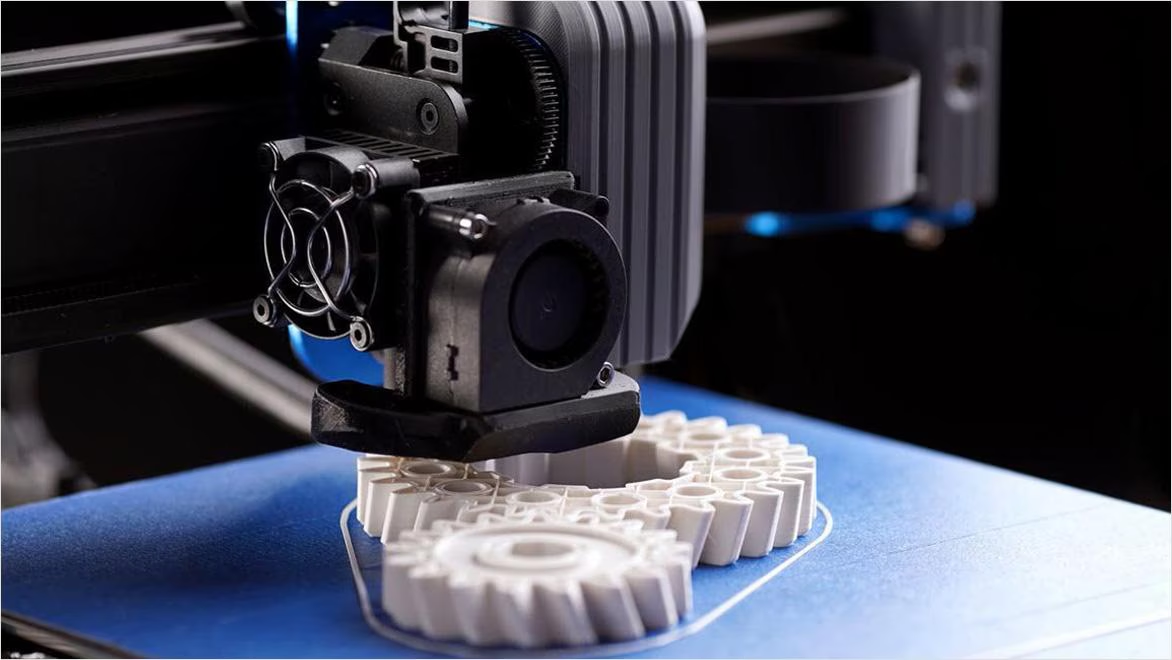

Fused Deposition Modeling (FDM)

FDM uses heated and extruded thermoplastic filament. CAD models control the 3D printer nozzle, which deposits the filament layer by layer to create final products.

Advantages: There is a wide selection of materials, such as ABS, PLA, etc., which are suitable for use in office environments. These materials are commonly employed in prototype design, educational settings, and household applications, and the cost is relatively low.

Limitations: It has lower precision; directly printed chips may encounter leakage issues, and the surface roughness is higher, so it will require post-processing.

Stereo Lithography Apparatus (SLA)

An ultraviolet laser solidifies liquid photosensitive resin layer by layer according to the machine instructions on a build platform. SLA produces highly detailed 3D parts with smooth finishes.

Advantages: It is high-precision and capable of manufacturing complex microfluidic structures, suitable for rapid iterative design in academic research.

Limitations: Traditional SLA struggles to achieve micron-level accuracy along the Z-axis, and it is prone to over-curing which leads to channel blockages. Moreover, high-resolution printers are expensive.

Selective Laser Sintering (SLS)

Uses an infrared laser to sinter powdered material (like nylon or metal) layer by layer, enabling complex geometries and functional prototypes or end-use parts.

Advantages: It is suitable for the manufacture of high-temperature resistance and high-strength, complex components or molds, especially in the production of large and complex parts in fields such as aerospace and automotive manufacturing.

Limitations: The prototype’s cost is high, its surface roughness is relatively high, and the manufacturing process may produce harmful gases.

3DP (3D Printing) Jetting Technology

This printing technology jets binder onto a powder bed material to build a 3D object layer by layer.

Advantages: 3D jetting allows for the simultaneous use of multiple materials, making it suitable for rapid prototyping, small batch production, and manufacturing complex multicolored models such as interior and exterior decorations, medical models, etc.

Limitations: The limited strength of the materials, issues with liquid leakage, and resolution limitations in inkjet printing restrict its applications.

These technologies vary in materials, resolution, and application suitability, but all enable the creation of customized, intricate objects with high precision and efficiency.

Future Trends in 3D Printing

3D printing technology will continue to make breakthroughs and innovations in equipment, materials, and applications.

Equipment: Trends for 3D printing include high precision, high speed, and large-scale 3D printing devices becoming mainstream.

Multi-Material Printing: More new materials will be developed and applied, covering a wider range of application areas.

Personalization and Customization: Traditional manufacturing often focuses on mass production, whereas 3D printing technology enables small batch and customized production. In the future, as consumer demand for personalization continues to grow, personalized customization will become an important direction for the development of the 3D printing industry.

Green and Sustainable Development: Traditional manufacturing often generates a large amount of waste and pollution; however, 3D printing technology enables efficient use of materials and reduces waste production.

Intelligent Manufacturing: 3D printing technology will deeply integrate with emerging technologies such as smart manufacturing and the Internet of Things (IoT). In the future, 3D printing technology will deeply integrate with these technologies to achieve digital and intelligent manufacturing.

Cross-Disciplinary Integration and Collaborative Innovation: The 3D printing industry will integrate across different sectors, achieving complementary advantages and collaborative innovation. For example, 3D printing will merge with fields such as biomedicine, education, and the arts, creating more innovative products and services.

Regulatory Challenges: Evolving regulations will address IP, safety, and certification issues as 3D printing technologies mature.

These advancements promise to reshape manufacturing, health care, and beyond, ushering in an era of innovation and efficiency.

PCB Factory Gallery