14+

Years Experience

98.15%

On-Time Delivery

96%

customer satisfaction rate

99%

Quality Pass Rate

How Much Do Sheet Metal Fabrication Services Cost?

The cost of sheet metal fabrication can vary widely, but generally falls within the range of $25 to $150 per hour for labor. However, the total cost will depend on several factors, such as the complexity of the design, the type and thickness of the metal used, the quantity of parts needed, the required finishing processes, and the turnaround time. Simple projects may cost a few hundred dollars, while more complex, large-scale fabrications can run into thousands of dollars.

Note: For exact prices, contact PCBAndAssemly directly. Our team will look at your project needs and give you a clear quote. Costs change based on what you need and current market prices. We offer fair pricing for all sheet metal fabrication projects. Get in touch with us today to discuss your needs.

How the Sheet Metal Fabrication Process Works

The typical sheet metal fabrication process includes these sub-processes:

Our Sheet Metal Fabrication Capabilities

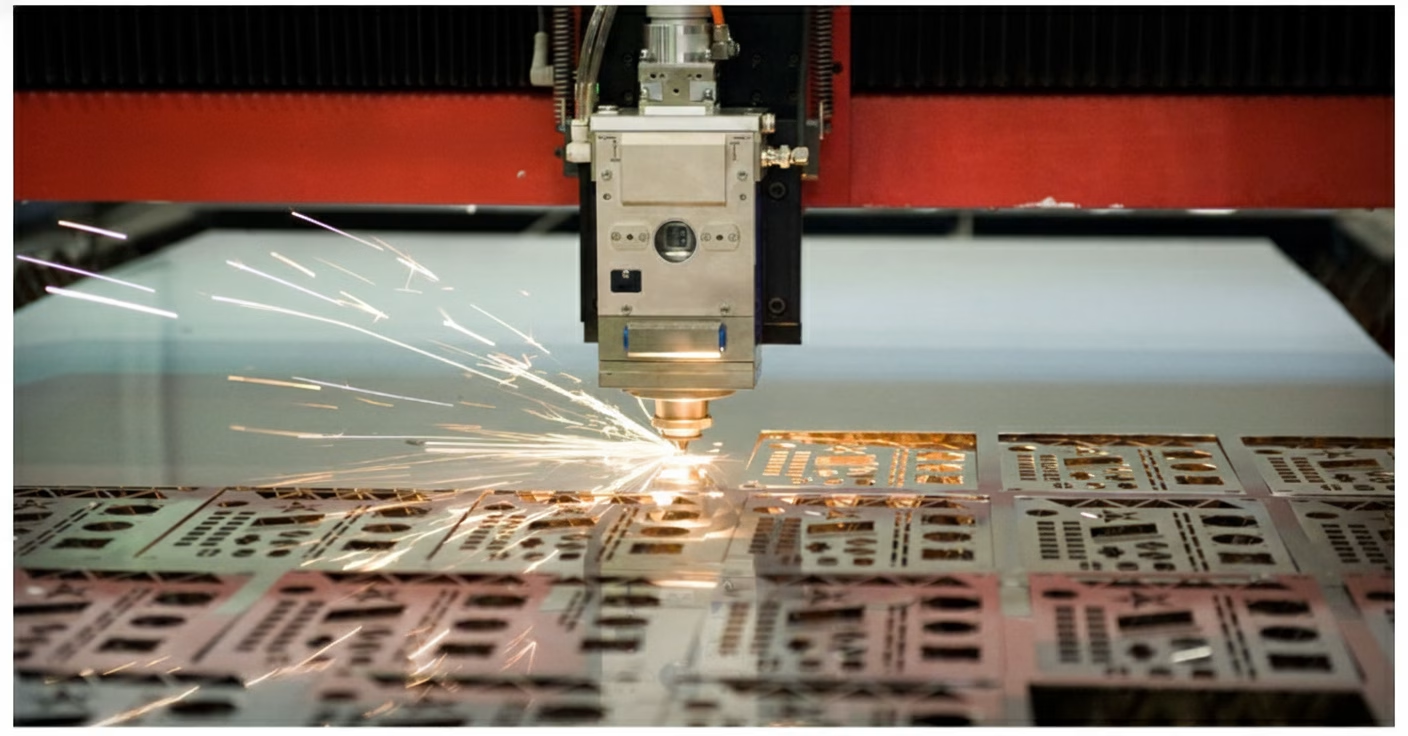

Laser Cutting

Processing Accuracy: ±0.05mm/100mm

Materials: The thickness varies with different materials, typically carbon steel plate ≤12mm, stainless steel plate ≤10mm, and non-metallic materials ≤20mm.

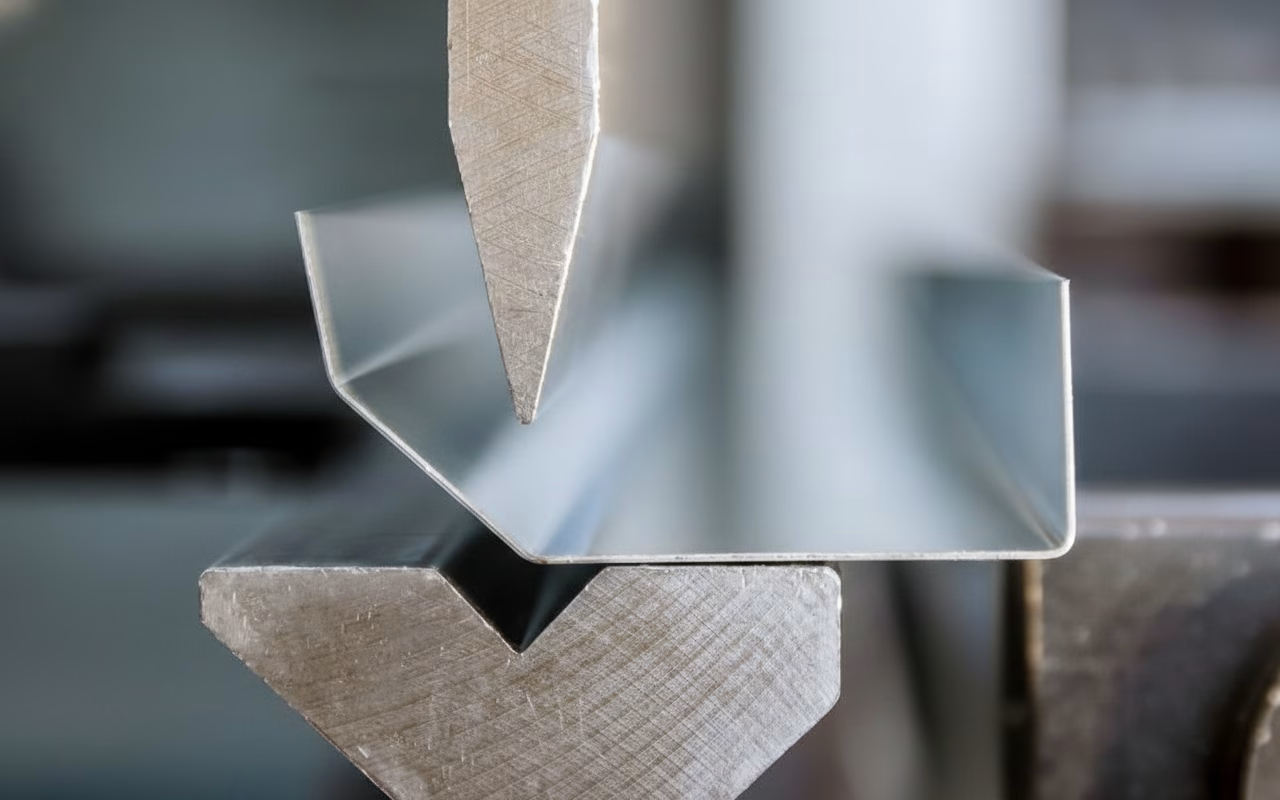

Processing Accuracy: ±0.05mm/100mm

Materials: Aluminum and steel.

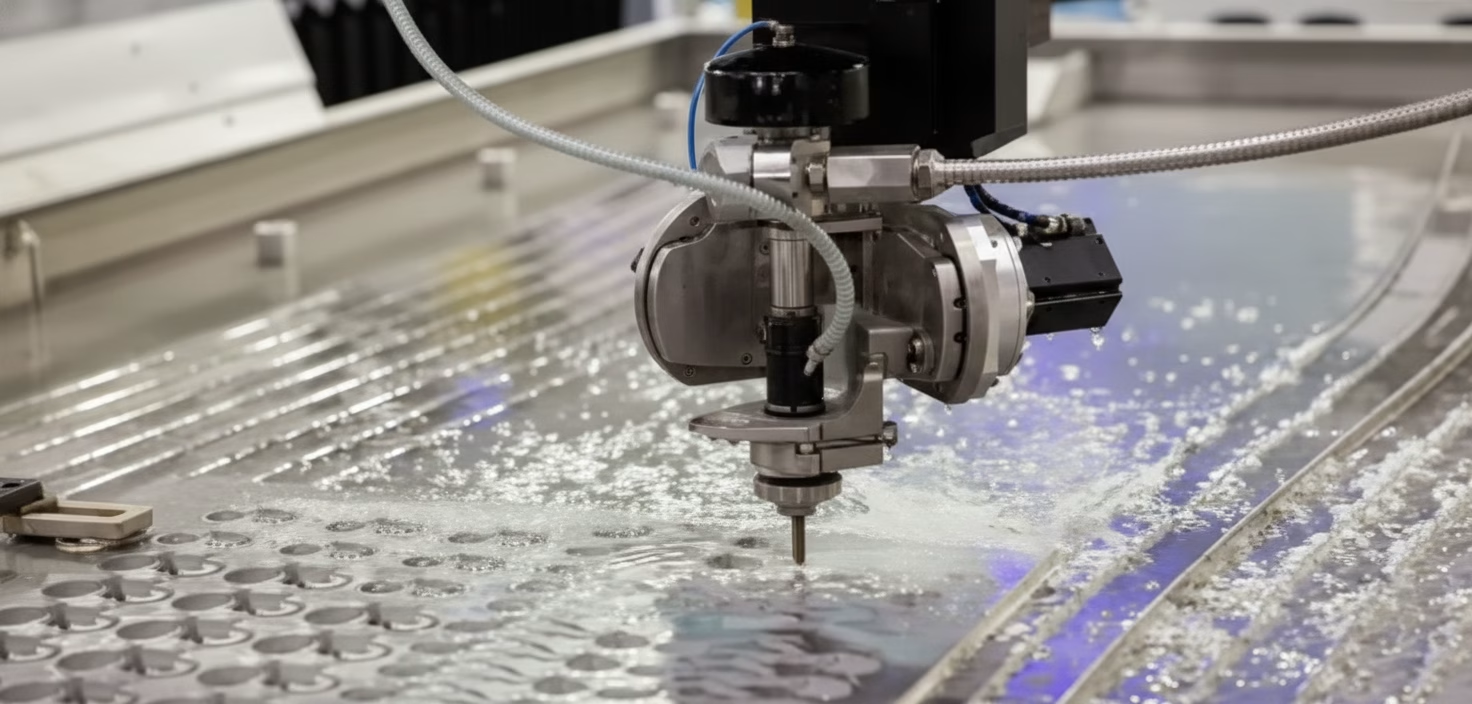

Processing Accuracy: ±0.02mm/100mm

Materials: Cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU), aluminum sheet (6061, 5052, 1010, 1060, 6063, hard aluminum, etc.)

Sheet Metal Fabrication: Advantages and Disadvantages

Why Choose Us as Your Sheet Metal Fabrication Service Provider?

Our one-stop prototype and product processing services employ advanced CNC machining, 3D printing, silicone molding, rapid molding, injection molding, sheet metal processing, along with numerous surface treatment technologies. We combine numerous processes to ensure precise and accurate results.

As your best sheet metal fabrication service provider, our professional team guarantees quick quotations and real-time tracking of order status.

PCBAndAssembly has a robust quality control system and has received several certifications, including ISO 9001, ISO 14001, IATF 16949, and ISO 27001. We aim to be your go-to Sheet Metal Fabrication company by providing excellent service, affordable prices, and exceptional products.

Applications of Sheet Metal Fabrication

PCB Factory Gallery