14+

Years Experience

98.15%

On-Time Delivery

96%

customer satisfaction rate

99%

Quality Pass Rate

How Much Do Injection Molding Services Cost?

The cost of injection molding services typically depends on several key factors: the complexity and size of the part, the material used, the production volume, and the mold (tool) cost. Mold costs can range from $1,000 for simple designs to over $100,000 for complex, multi-cavity molds. Material costs vary widely, from $1-$3 per pound for common plastics to $30+ per pound for specialized engineering plastics. Machine time and labor also contribute to the overall cost.

For high-volume production, the per-unit cost decreases significantly as the mold cost is spread over more parts. While initial tooling costs can be high, injection molding becomes more cost-effective for large production runs, often resulting in lower per-unit costs compared to other manufacturing methods.

Note* For exact prices, contact PCBAndAssembly directly. Our team will look at your project needs and give you a clear quote. Costs change based on what you need and current market prices. We offer fair pricing for all injection molding projects. Get in touch with us today to discuss your needs.

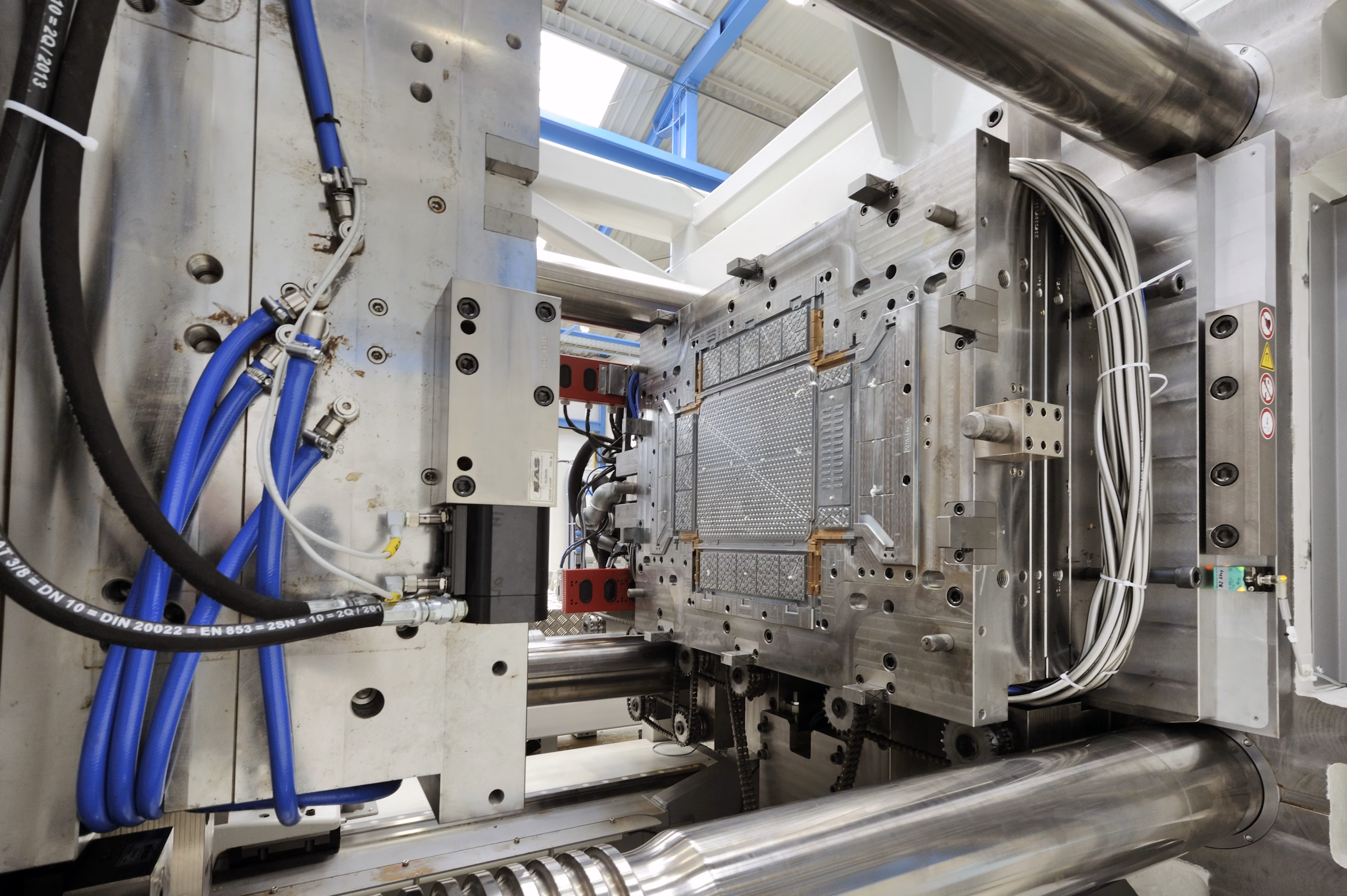

How Injection Molding Works?

Let’s break down the process step by step for a comprehensive understanding.

1. Material Preparation

The first step in injection molding involves preparing the raw material:

- Plastic pellets (also called resin) are loaded into a hopper.

- These pellets can be made from various types of polymers, such as polypropylene, polyethylene, or polystyrene.

- Additives like colorants or reinforcing agents may be mixed with the pellets.

2. Melting the Plastic

Once the material is loaded, it needs to be melted:

- The pellets are fed into a heated barrel.

- Inside the barrel is a large screw that rotates.

- As the screw rotates, it moves the pellets forward.

- The combination of heat from the barrel and friction from the screw melts the plastic.

After the plastic is fully melted, it’s ready for injection:

- The molten plastic is forced into a mold cavity under high pressure.

- This injection is typically done very quickly, often in less than a second.

- The pressure can range from 10,000 to 30,000 psi, depending on the part being made.

Once the mold is filled, there’s a brief pause called the dwelling phase:

- Additional pressure is maintained to ensure all mold cavities are filled.

- This helps compensate for material shrinkage as it begins to cool.

The cooling phase is crucial for part quality:

- The molten plastic begins to cool and solidify as soon as it touches the mold.

- Cooling channels in the mold circulate water or another coolant to speed up this process.

- The cooling time depends on factors like part thickness and material properties.

After the part has cooled sufficiently:

- The mold opens.

- Ejector pins push the finished part out of the mold.

- In some cases, robots or human operators remove the part.

The final step prepares the machine for the next cycle:

- The mold closes.

- The screw retracts, allowing more plastic pellets to fall in front of it.

- The process then repeats from step 2.

Our Injection Molding Capabilities

Quick Mold

Rapid Mold Process: We employ CNC rough machining, EDM (electrical discharge machining), mold fitting, mold debugging, mold assembly, mold installation, and injection molding to produce the mold and product swiftly.

Next, the process involves removing injection molding residuals, retrieving the finished products, and trimming residuals. We’ll finish off the process with a manual quality inspection as well as a 3D inspection. The mold and product can be completed in 10 days.

Processing Accuracy: ±0.1 mm/100 mm

Injection Molding Tonnage: 80 to 3000 tons

Materials:

| ✔️ PET (Transparent) | ✔️ PPSU |

| ✔️ POM | ✔️ SAN |

| ✔️ PC (Transparent, Opaque, Medical Grade, Flame Retardant) | ✔️ ABS (Transparent, Flame Retardant) |

| ✔️ PC+GF | ✔️ ABS+UV resistant |

| ✔️ PBT | ✔️ ABS+GF |

| ✔️ PBT+GF | ✔️ PC+ABS (Standard, Medical Grade, Flame Retardant, High Gloss) |

| ✔️ PA6 | ✔️ PP (transparent, opaque) |

| ✔️ PA6+GF | ✔️ PP+GF |

| ✔️ PA66 | ✔️ PE (Transparent, Opaque, +PE Modified) |

| ✔️ PA66+GF | ✔️ GPPS (Transparent) |

| ✔️ PPA | ✔️ HIPS (Natural Color, Modified) |

| ✔️ PPA+GF | ✔️ ABA (Transparent) |

| ✔️ PPS | ✔️ TPU (Transparent, Opaque, Various Hardness) |

| ✔️ PMMA | ✔️ TPE (Transparent, Opaque, Various Hardness) |

Advantages and Disadvantages of Injection Molding

Why Choose Us as Your Injection Molding Service Provider?

As your top injection molding service supplier, our skilled staff provides timely online injection molding quote and real-time order status tracking.

We combine numerous processes to provide one-stop prototype and product processing services, including advanced CNC machining, 3D printing, silicone molding, rapid and injection molding, sheet metal processing, and multiple surface treatment technologies.

We are ISO 9001, ISO 14001, IATF 16949, and ISO 27001 certified, and we have a well-established quality control system.

With superior client satisfaction, high-quality goods, and affordable rates, we aspire to be the best choice for all of your injection molding service requirements.

Contact us today to receive an accurate quote or consultation. We look forward to working with you on your next project.

PCB Factory Gallery