PCB Hardware Selection: How to Choose the Right Components

From the control ICs that process information to the steadfast passive components that shape electrical signals, each piece of PCB hardware plays a vital role.

Get Your PCB Quote!

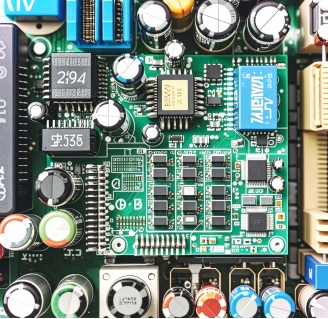

In our increasingly connected world, electronics are everywhere—from the smartphones in our pockets to the complex machinery in factories. At the heart of nearly every electronic device lies a Printed Circuit Board(PCB), a foundational element that provides the electrical connections and mechanical support for electronic components. But a PCB is more than just a green board; it’s a meticulously designed ecosystem of components, each playing a critical role in the device’s functionality. This ecosystem, often referred to as PCB hardware, is integral for everything from data cabinets and home appliances to office equipment and industrial controls. Understanding these components is paramount for anyone involved in electronics design, manufacturing, or even advanced hobbyist projects.

This comprehensive guide delves into the intricate world of PCB hardware, exploring the diverse components that enhance performance, ensure reliability, and enable the sophisticated operations we take for granted. We’ll break down classifications, analyze core electronic components, and discuss best practices for selection and design.

1. Why PCB Hardware Matters?

The performance, reliability, and longevity of any electronic device are directly tied to the quality and suitability of its PCB hardware. Choosing the right components isn’t merely about making a circuit work; it’s about optimizing its efficiency, managing thermal performance, ensuring signal integrity, and meeting specific application requirements. For instance, in high-frequency applications, the choice of substrate material and connector type can significantly impact data transmission speeds and signal loss. In power applications, the correct power management chips and passive components are crucial for stable voltage regulation and preventing overheating.

Incorrectly chosen or substandard PCB components can lead to a myriad of issues, including:

- Reduced operational lifespan due to component failure.

- Intermittent functionality or complete system failure.

- Increased power consumption and heat generation.

- Compromised signal integrity, leading to data errors.

- Difficulty in manufacturing and increased production costs.

Therefore, a deep understanding of PCB hardware is not just beneficial, but essential for engineers and designers aiming to create robust, high-performance electronic products. The initial investment in selecting the right hardware ultimately pays off in device stability, user satisfaction, and overall product success.

2. Understanding PCB Classification Systems

Before diving into individual components, it’s helpful to understand how PCBs themselves are classified, as this often dictates the type of hardware and design considerations. PCBs can be categorized in several ways:

Classification by Structural Layers

- Single-Layer PCBs:The simplest type, with components mounted on one side and conductors on the other. Ideal for low-cost, low-density applications.

- Double-Layer PCBs:Feature conductive layers on both sides, connected by vias. They offer higher density and more complex routing.

- Multi-Layer PCBs:Consist of three or more conductive layers separated by insulating materials. They are essential for complex electronics, high-speed signals, and power distribution, providing superior signal integrity and noise reduction.

Classification by Base Material

- FR-4 (Flame Retardant 4):The most common PCB material, made of woven fiberglass cloth with an epoxy resin binder. It is known for its good balance of electrical, mechanical, and thermal properties.

- Metal Core PCBs (MCPCBs):Utilize a metal base (e.g., aluminum, copper) for improved heat dissipation. They are ideal for high-power LED lighting and automotive applications.

- Flexible PCBs:Made from flexible plastic substrates, allowing the board to bend and conform to various shapes. They are used in compact, wearable devices.

- Rigid-Flex PCBs:Combine rigid and flexible board technologies, offering the best of both worlds for challenging form factors and dynamic applications.

- High-Frequency/RF PCBs:Employ specialized materials like PTFE (Teflon) or ceramic-filled hydrocarbons, offering low dielectric loss and stable performance at high frequencies, crucial for telecommunications and radar systems.

Classification by Special Processes

Beyond material and structure, PCBs can also be classified by specific manufacturing processes or features, such as High-Density Interconnect (HDI) PCBs, boards with embedded components, or those designed for extreme environmental conditions.

3. Essential PCB Hardware Components Explained

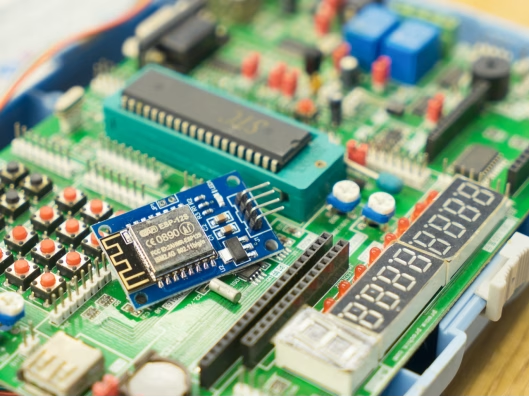

The true magic of a PCB lies in the synergy of its diverse components. Let’s explore the core electronic components that populate these boards, detailing their functions and applications.

3.1 Main Control Chips

Often referred to as the “brain” of an electronic device, main control chips are responsible for executing instructions, processing data, and managing overall system operations. They come in various forms, each suited for different levels of complexity and performance.

- Microcontrollers (MCUs):Integrated circuits that contain a processor core, memory (RAM, ROM, flash), and programmable input/output peripherals on a single chip. They are designed for embedded applications requiring real-time control, such as washing machines, remote controls, and automotive systems.

- Microprocessors (MPUs):More powerful than MCUs, MPUs primarily consist of a Central Processing Unit (CPU) and rely on external memory and peripherals. They are found in computers, servers, and complex embedded systems that require significant processing power and memory.

- Digital Signal Processors (DSPs):Specialized microprocessors designed to perform high-speed mathematical operations for signal processing tasks, like audio and video processing, telecommunications, and radar.

- Field-Programmable Gate Arrays (FPGAs):Integrated circuits that can be configured by the user after manufacturing. They offer high parallel processing capabilities and are ideal for applications requiring custom logic, rapid prototyping, and hardware acceleration.

3.2 Driver Chips

Driver chips act as intermediaries, translating control signals from the main control unit into the specific electrical signals required to operate other components or systems. They are crucial for interfacing and managing external devices.

- Motor Drive Specialization:These chips control various types of motors (DC, stepper, brushless DC) by regulating current, voltage, and direction. They are vital in robotics, automation, and any device involving motion.

- Display Drivers:Responsible for controlling pixels and light output on LCD, LED, and OLED displays. They manage the complex array of signals needed to render images and text.

- Power Drivers:Used to switch high currents or voltages on and off, often in conjunction with power transistors. They are found in power supplies, lighting control, and industrial equipment.

- LED Drivers:Specifically designed to regulate current flowing through LEDs, ensuring consistent brightness and protecting them from damage due to voltage fluctuations.

3.3 Power Management Chips

Efficient and stable power delivery is critical for any electronic circuit. Power management chips ensure that each component receives the precise voltage and current it needs, protecting the system from power fluctuations and optimizing energy consumption.

- Voltage Regulators:Maintain a constant output voltage regardless of input voltage fluctuations or load changes. Linear regulators (LDOs) are simple but less efficient, while switching regulators (buck, boost, buck-boost) offer higher efficiency.

- DC-DC Converters:Transform one DC voltage level to another. They are essential for battery-powered devices and systems requiring multiple voltage rails.

- Battery Management Systems (BMS):Monitor and manage rechargeable batteries, ensuring safe operation, optimal charging, and extended battery life.

- Power Factor Correction (PFC) Controllers:Improve the power factor of AC-DC power supplies, reducing reactive power and improving efficiency.

3.4 Passive Component

Passive components do not generate power but are fundamental for shaping signals, storing energy, and limiting current. Their accurate selection is vital for circuit stability and performance.

- Resistors:Limit current flow, divide voltage, and dissipate heat. Key parameters include resistance (ohms), tolerance (%), and power rating (watts).

- Capacitors:Store electrical energy, block DC current while allowing AC to pass, and filter noise. Important parameters include capacitance (Farads), voltage rating, and equivalent series resistance (ESR).

- Inductors:Store energy in a magnetic field, block high-frequency noise, and are used in filters and power converters. Key parameters are inductance (Henries) and current rating.

- Crystal Oscillators:Provide a stable clock signal for timing and synchronization in digital circuits. Defined by their resonant frequency (Hz).

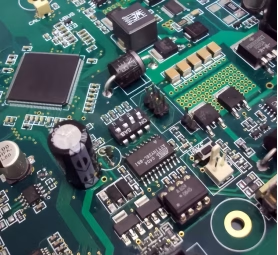

3.5 Semiconductor Discrete Devices

These individual semiconductor components perform specific functions like rectification, amplification, or switching.

1) Diodes: Allow current to flow in only one direction. Used for rectification (converting AC to DC), voltage regulation (Zener diodes), and protecting circuits from reverse voltage.

2) Transistors: Fundamental building blocks for amplification and switching.

- Bipolar Junction Transistors (BJTs):Current-controlled devices, used for amplification and switching. They have three operating states: Cut-off (off), Active (amplification), and Saturation (on).

- Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs):Voltage-controlled devices, offering high input impedance, faster switching speeds, and lower on-state resistance compared to BJTs, making them ideal for power switching applications.

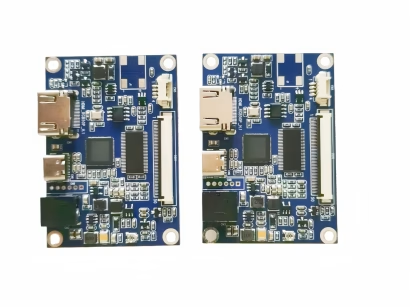

3.6 Connectors

They provide the physical and electrical interface between different parts of a circuit board or between the board and external devices. Their structural classification varies widely:

- Board-to-Board Connectors:Link multiple PCBs within a system.

- Wire-to-Board Connectors:Connect discrete wires to a PCB, commonly used for power or data signals.

- Input/Output (I/O) Connectors:Enable external devices to connect to the PCB (e.g., USB, HDMI, Ethernet, audio jacks).

- RF Connectors:Specialized connectors (e.g., SMA, BNC) designed for high-frequency signals, minimizing signal loss and interference.

- Power Connectors:Designed to handle higher currents for power delivery to the board or other components.

Key considerations for connectors include pins, pitch, current rating, voltage rating, mating cycles, environmental sealing, and mounting style.

4. Selecting the Right PCB Hardware

Choosing the appropriate PCB hardware is a multi-faceted decision process that goes beyond simply finding a component that “fits”. It requires a holistic understanding of the application, environment, and performance goals. Here are key factors to consider:

- Application Requirements:What is the device’s primary function? What are its speed, power, and signal integrity requirements? For example, a high-frequency communication device will demand different components than a low-power IoT sensor.

- Environmental Conditions:Will the device operate in extreme temperatures, high humidity, or vibrating environments? Industrial and automotive applications often require ruggedized components with extended temperature ranges.

- Performance Specifications:Closely examine datasheets for critical parameters like voltage ratings, current ratings, frequency response, power dissipation, and accuracy. Ensure these specifications meet or exceed your design needs.

- Cost vs. Performance:Balance the budget with performance expectations. Sometimes, a slightly more expensive component can significantly improve reliability or simplify design, leading to overall cost savings.

- Availability and Lead Times:Consider the supply chain. Are the components readily available from multiple manufacturers? What are the typical lead times, especially for high-volume production?

- Footprint and Package Size:Ensure the component’s physical dimensions and package type are compatible with your PCB layout and space constraints.

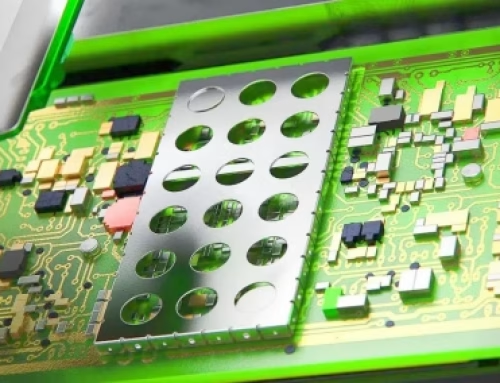

- Thermal Management:For power-intensive components, evaluate their thermal characteristics and ensure adequate heat dissipation mechanisms are in place (e.g., heatsinks, proper PCB layout).

- Regulatory Compliance:Check for necessary certifications (e.g., RoHS, CE, FCC) relevant to your target market.

5. Best Practices for PCB Design

The choice of hardware is only half the battle; how these components are integrated into the PCB design is equally crucial. Adhering to best practices in PCB design ensures manufacturability, reliability, and optimal performance.

- Schematic Design:Start with a clear and well-organized schematic. Use standard symbols, ensure proper net labeling, and verify power and ground connections. This forms the blueprint for your hardware integration.

- Component Placement:Group related components, minimize trace lengths for high-speed signals, and place decoupling capacitors close to ICs. Consider thermal management early by placing heat-generating components strategically.

- Trace Routing:Follow design rules for trace width, spacing, and impedance control, especially for high-frequency signals. Use ground planes to improve signal integrity and reduce electromagnetic interference (EMI).

- Power Distribution Network (PDN):Design a robust PDN to deliver stable power to all components. Use appropriate trace widths for current carrying capacity and proper decoupling.

- Design for Manufacturability (DFM) and Assembly (DFA):Consider manufacturing tolerances, component spacing for automated assembly, and test point accessibility. Early DFM/DFA considerations can significantly reduce production costs and time.

- Signal Integrity (SI) and Power Integrity (PI): Address potential SI/PI issues through careful impedance matching, proper termination, and effective ground plane design, particularly for high-speed or high-frequency designs.

- Layer Stack-up Optimization:For multi-layer PCBs, optimize the layer stack-up to provide clear signal paths, effective shielding, and efficient power distribution.

6. PCB Hardware FAQs

Active components require an external power source to function (e.g., integrated circuits, transistors, diodes), while passive components do not generate power but rather dissipate, store, or control it (e.g ., resistors, capacitors, inductors).

Power management chips are crucial for regulating voltages, converting power efficiently, and protecting circuits from power fluctuations. They ensure that each component receives stable, clean power, which is vital for device reliability, performance, and extending battery life in portable electronics.

No. The choice of connector depends on various factors including the signals being transmitted (power, data, RF), current/voltage requirements, environmental conditions, mating cycles, and physical space. Using an inappropriate connector can lead to signal degradation, unreliable connections, or even safety hazards.

FR-4 (Flame Retardant 4) is a glass-reinforced epoxy laminate material. It’s widely used due to its excellent balance of electrical, mechanical, and thermal properties, good manufacturability, and cost-effectiveness, making it suitable for a vast range of electronic applications.

7. Summary

The Printed Circuit Board is the backbone of modern electronics, and its performance is directly dictated by the quality and thoughtful integration of its hardware components. From the intelligent main control chips that process information to the steadfast passive components that shape electrical signals, each piece of PCB hardware plays a vital role. Understanding PCB classifications, the distinct functions of core electronic components like driver chips, power management units, and semiconductors, and the nuances of connectors is fundamental. Furthermore, making informed decisions during component selection and adhering to robust PCB design best practices are indispensable steps towards creating reliable, efficient, and high-performance electronic devices. As technology continues to advance, the mastery of PCB hardware and design will remain a cornerstone for innovation.

Key Takeaways

- PCB hardware is critical for the functionality, reliability, and longevity of all electronic devices.

- Component selection must be holistic, considering application, environment, performance, cost, and availability.

- Core components like MCUs, driver chips, and power management ICs are the intelligence and control centers of a PCB.

- Passive components (resistors, capacitors, inductors) are essential for signal shaping, energy storage, and current control.

- Adhering to PCB design best practices (schematics, placement, routing, DFM/DFA) is crucial for optimal performance and manufacturability.

Get Your PCB Quote!