A Complete Guide to Rigid-Flex PCB

Explore everything you need to know about rigid flex PCB in this complete guide, including benefits, applications, fabrication.

Get Your PCB Quote!

Table of Contents

- 1. Apakah PCB Tegar-Flex?

- 2. Mengapa Menggunakan Papan Flex Tegar?

- 3. Pertimbangan reka bentuk

- 4. Proses Fabrikasi

- 5. Bahan Digunakan

- 6. Aplikasi Merentas Industri

- 7. Faktor Kos

- 8. Kelebihan Reka Bentuk Hibrid

- 9. Masa Depan Teknologi PCB Flex

- 10. Mencari Pengeluar yang Tepat

- 11. PCB Tegar-Flex Soalan Lazim

- 12. Ringkasan

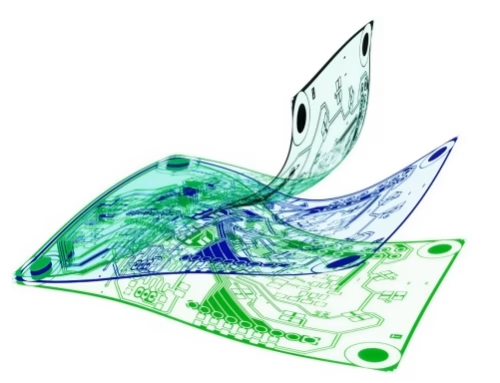

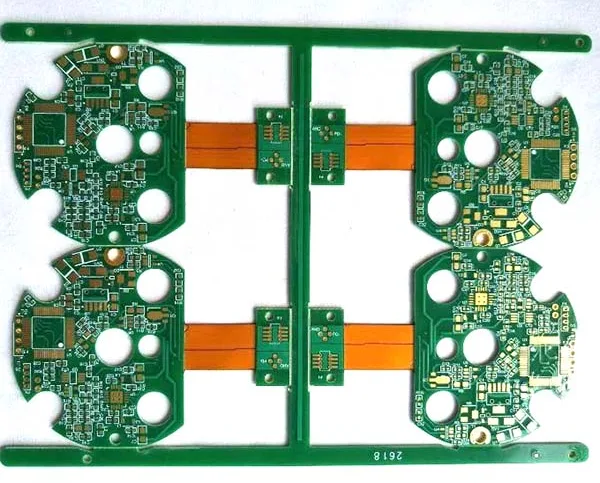

Rigid flex PCB technology combines the strength of rigid boards with the flexibility of flex circuitry, providing designers with more options. These hybrid circuit boards provide support for small and lightweight devices if space for conventional routing is scarce.

From aerospace to consumer electronics, industries and designers everywhere are considering these hybrid solutions in order to meet modern demands. Let’s explore what lies so strongly inside them!

1. What Is a Rigid-Flex PCB?

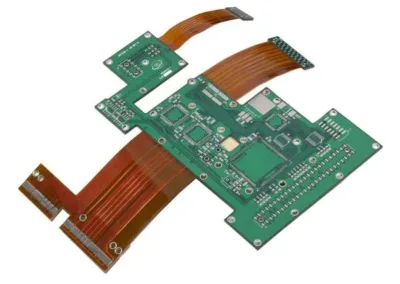

A rigid flex board is a design that involves a combination of flexible and solid layers, and the layers are laminated to form a single body. This design lets it bend where needed, while staying strong and stable in other parts.

Unlike traditional PCBs, the connector or cable between sections is not needed in hybrid boards, thus reducing component count and improving electrical performance.

2. Why Use a Rigid Flex Board?

The top reason to adopt a flexible rigid PCB for applications is that of reliability. They reduce the chances of failure considerably by decreasing the total number of solder joints and interconnects involved.

The boards are all the more suitable for dynamic applications in which continuous flexing is required. Foldable gadgets, cameras, or wearable tech are examples. Thanks to design freedom and increased mechanical stability.

3. Design Considerations

Designing a PCB rigid flex requires a unique approach. You must carefully define the rigid and flexible zones early in the layout stage.

The flexible parts often follow curved paths, which need special trace routing and material selection. Proper stack-up design, controlled impedance, and stress relief features are essential.

Also, keep in mind the final 3D form of the product. These boards are usually bent or folded in use, so ensuring mechanical resilience is key.

4. Fabrication Process

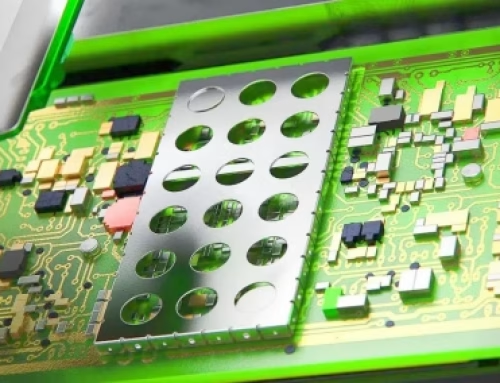

Designing a rigid flex rigid PCB requires a special approach. Every rigid and flexible zone must be defined early in the layout stage. It involves several lamination cycles, precise drilling, and special handling techniques.

Fabrication begins with making the flexible circuit layers; they are then joined with the rigid sections through a multistep lamination process that creates a smooth and continuous transition between both regions.

All steps must be done correctly to ensure signal integrity and mechanical strength.

5. Materials Used

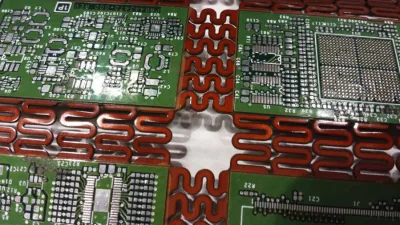

The materials in the flex rigid PCB manufacturer production include polyimide for flex layers and FR4 for rigid areas. They favour good thermal and mechanical properties.

Adhesive systems need to resist temperature changes as well as the bending cycles. Copper foils, rolled and annealed, are mostly used for flex zones, while electrodeposited ones are used for rigid zones.

The material selection is a critical factor affecting the long-term performance and reliability.

6. Applications Across Industries

The use of quick turn rigid flex PCB is going ahead for industries that value compact design and robust performance. The aerospace sector utilizes them in avionics and control systems, considering light weight and reliability.

They also find use in the medical field for applications such as pacemakers and imaging equipment. Therefore, these PCBs with their small form factor and flexibility are suitable for wearable and implantable solutions.

From the consumer side, these PCBs offer folding and bending options that have been harnessed to form new product applications such as foldable phones and smartwatches.

7. Cost Factors

Rigid flex PCB cost can be higher than traditional designs. This is due to complex fabrication, material selection, and testing requirements.

According to many manufacturers, the total cost of implementation on the customer site may be less because of reduced assembly time, fewer connectors, and an increased reliability count. Therefore, engineers should weigh the upfront costs against the long-term ones.

8. Advantages of Hybrid Designs

Using a rigid and flex PCB offers multiple benefits. These also help with enhanced signal integrity, decreased weight, and improved mechanical strength. The hybrid layout supports the elimination of cumbersome connectors and cabling.

That translates into streamlined design, better EMI performance, and increased reliability.

9. Future of PCB Flex Technology

The increasing growth of IoT and wearable technologies will massively increase the demand for rigid flex circuit boards. Parallel to that, advancements in material requirements, miniaturization, and manufacturing will further enhance their capabilities.

Manufacturers are currently considering improvements to bend radius support and embedded component options. The aim is to provide more design flexibility and functionality without increasing the footprint.

This makes PCB flex rigid designs a cornerstone of next-generation electronics.

10. Finding the Right Manufacturer

Choosing the perfect rigid flex PCB fabrication partner is very important. One should consider experienced teams that have proven competencies in the manufacturing of both rigid and flex technologies.

Inquire about testing methods, deadlines, and materials. Having a competent rigid flex PCB supplier will ensure that the final product meets performance expectations.

A trusted partner helps with costly design errors and delays in production.

11. Rigid-Flex PCB FAQs

The rigid flex-type engineering board is basically a mixture of flexible and rigid sections so that it can bend in some regions while remaining stiff in others.

Integration of flexible and rigid materials in one unit for rigid flex PCB is, in contrast to normal boards, in which two are separate entities joined by connectors, better for reliability.

They are used extensively by aerospace industries, medical device companies, consumer electronics, and the military.

The price depends on many factors-difficulty in design, materials used, and volume ordered-but generally, it tends to be on the higher side as compared to standard PCBs.

Yes, the flexible sections of a rigid flex PCB are made to be bent repeatedly for use in dynamic environments.

Conventional material combinations employ polyimide as flex parts and FR4 as rigid zones, with a variety of adhesives and copper foils.

Yes, in fact, several manufacturers provide fast-turn prototyping services that foster rapid development cycles.

You should also review that they carry the relevant experience and certifications, together with any important testing to meet industry standards.

12. Summary

These days, the rigid flex printed circuit boards provide unmatched flexibility and strength required by compact and high-performance electronics. They are flexibly used in different sectors as they stitch together the best from both the rigid and the flexible varieties.

Be it the development of next-generation medical devices or foldable consumer tech, rigid flex PCB technology has got you covered for a reliable, space-saving solution. The investment made in the new technology today can readily add future-proofing to product designs. Don’t ask for samples if you can’t be bothered to reply.

Table of Contents

- 1. Apakah PCB Tegar-Flex?

- 2. Mengapa Menggunakan Papan Flex Tegar?

- 3. Pertimbangan reka bentuk

- 4. Proses Fabrikasi

- 5. Bahan Digunakan

- 6. Aplikasi Merentas Industri

- 7. Faktor Kos

- 8. Kelebihan Reka Bentuk Hibrid

- 9. Masa Depan Teknologi PCB Flex

- 10. Mencari Pengeluar yang Tepat

- 11. PCB Tegar-Flex Soalan Lazim

- 12. Ringkasan

Get Your PCB Quote!