Quick Turn PCB

Assembly Services

PCBAndAssembly delivers fast, high-quality PCB fabrication and assembly in 24 hours to 7 days, depending on design guidelines, board layers, order quantity, and surface finish. As a trusted PCBA manufacturer, we serve clients worldwide, especially in the USA, ensuring speed, precision, and reliability.

ISO 9001/UL Certified

PCB Assembly Specialists

On Time Delivery 98.15%

Quality Pass Rate 99%

Delivery Guarantee

ISO 9001/UL Certified

PCB Assembly Specialists

On Time Delivery 98.15%

Quality Pass Rate 99%

Delivery Guarantee

Quick-turn PCB assembly refers to a process where printed circuit boards are manufactured and assembled in a short time, usually within 24 hours to 7 days max.

Fab houses initially used this quick-turn assembly process for low-volume PCB production and prototyping. However, changing user requirements and recent advancements in PCB manufacturing have made it possible to use quick-turn production on high-volume orders.

Consequently, as an electronics designer or manufacturer, you can now use this process to get your products to market faster and gain a competitive edge. Let’s say you’ve discovered a new feature that has the potential to revolutionize the electronic product you’re selling. Someone else might have a similar idea, or your project might leak to the competition if it takes too long to implement. However, with quick-turn PCB assembly, you can execute and actualize your idea faster, and gain more market share before other players enter your space.

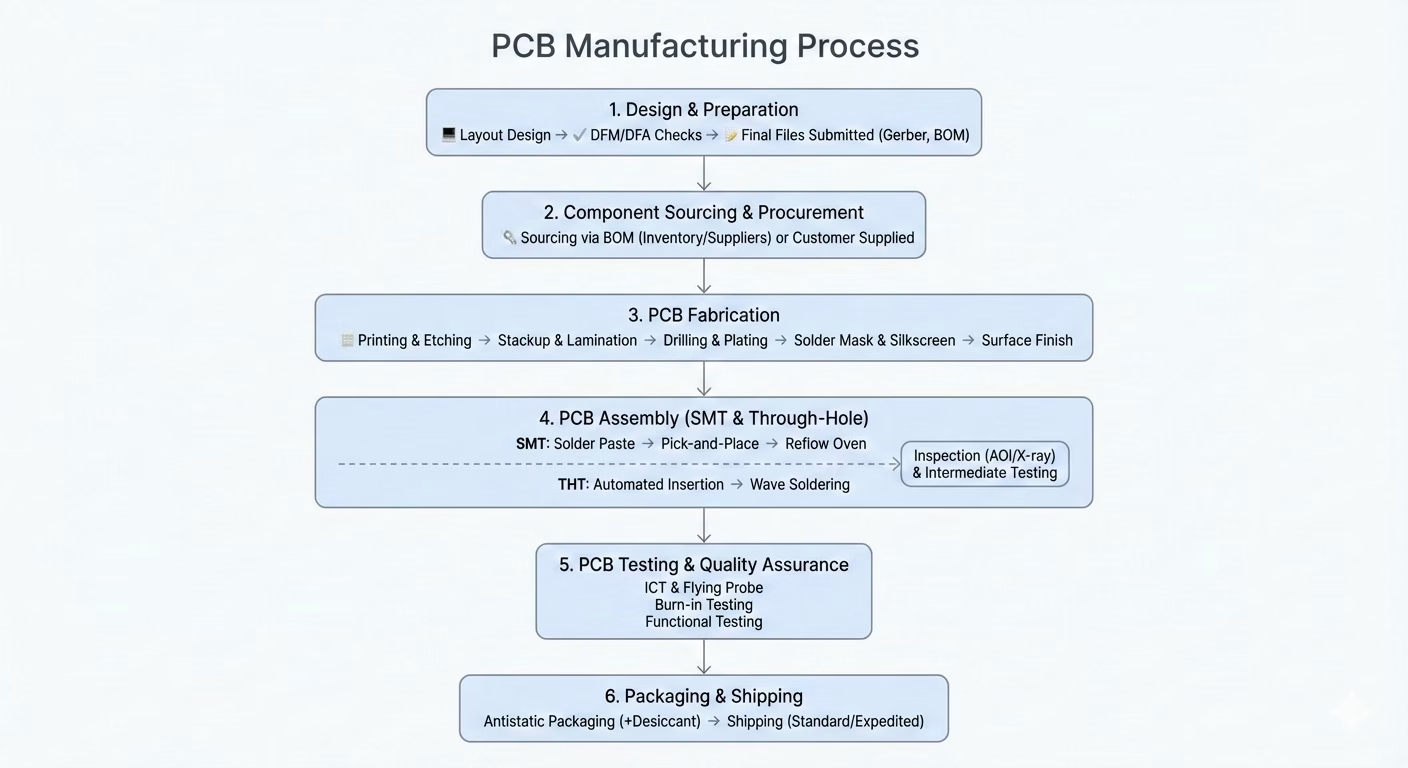

PCB Manufacturing Process

1. Design and Preparation

- PCBAndAssembly Technician analyzes a PCB design before approving it for production

- The process begins with PCB layout design, including defining electrical parameters, stack design, and component placement.

- Once finalized, essential design files (Gerber, Centroid, BOM, Pick-and-Place, NC Drill) are submitted for manufacturing.

- DFM (Design for Manufacturing) & DFA (Design for Assembly) checks ensure manufacturability by reviewing footprint design, component placement, solder mask clearances, and panelization.

- These checks help minimize defects, saving time and cost.

2. Component Sourcing and Procurement

- Components are sourced using the BOM and secured from in-house inventory or reliable suppliers (Avnet, Arrow, Future Electronics).

- Customers can supply their own components or have them shipped directly to the assembly plant.

3. PCB Fabrication

- Fabrication Steps: Printing PCB layout, etching, stack creation, hole drilling/plating, solder masking, silkscreen printing, and surface finishing.

- Rapid Prototyping Methods:

- Using simplified design rules.

- Prioritizing functional validation.

- Using simulated components.

- Running parallel prototype revisions.

- Multilayer boards require multiple etching/lamination cycles and additional inspection/testing for quality control.

4. PCB Assembly (SMT & Through-Hole)

- SMT Process:

- Solder paste applied via stencil.

- Components placed using pick-and-place machines.

- Reflow oven fuses components (210–250°C for lead-free solder).

- Inspection & testing (AOI, X-ray, Flying Probe, Bed of Nails).

- Through-Hole Assembly:

- Automated insertion mount machines insert components.

- Wave soldering ensures solid connections.

- Final testing & functional checks follow, ensuring assembly accuracy before shipment.

5. PCB Testing & Quality Assurance

Testing Methods Include:

- In-Circuit Testing (ICT): Automated testing via spring-loaded pins.

- Flying Probe Testing: Precision mobile probes check connectivity.

- Burn-in Testing: Extreme stress tests for reliability.

- Functional Testing: Simulates real-world operational conditions.

- Other tests include aging, fatigue, and environmental stress testing.

6. Packaging & Shipping

- Prototype boards are securely packaged in antistatic bags with ziplock or vacuum sealing and desiccant packets for moisture control.

- Customers can choose between expedited or standard shipping based on urgency and cost preferences.

PCB Assembly Services

Turnkey PCB Assembly

We handle everything from parts sourcing to final assembly, providing a hassle-free experience that ensures top-quality boards every time.

Prototype & Full Production Runs

Whether you need a few prototypes or large-volume batches, our flexible assembly services adapt to your project’s scope and timeline.

RoHS & Lead-Free Compliance

Stay environmentally responsible with our compliant assembly processes, offering RoHS and lead-free options for safe, reliable builds.

Single-Sided, Double-Sided, or Mixed

No matter the complexity, we can assemble boards of all configurations—single-layer, multi-layer, or a mix—to match your exact specifications.

Small Quantities & High-Volume Capabilities

From one-off prototypes to bulk orders, we accommodate projects of all sizes without compromising on quality or turnaround time.

Trusted by Over 3,000 Customers Worldwide

Join our growing community of satisfied clients who rely on our dependable assembly expertise and dedicated customer support.

Technical Capabilities

Capabilities & Services

PCB Factory Gallery