14+

Years Experience

98.15%

On-Time Delivery

96%

customer satisfaction rate

99%

Quality Pass Rate

Looking for Cost-effective, High-quality CNC Machining Services?

Are you looking for world-class CNC machining service provider? PCBAndAssembly specialize in delivering high-precision CNC machining with a focus on quality, efficiency, and customer satisfaction. As a premier CNC machining partner trusted by industry leaders across the United States, we deliver precision-engineered solutions that drive innovation and efficiency in American manufacturing.

Our CNC Machining Capabilities

Metal CNC Machining Products

Metal CNC Product Processing: We prepare the raw materials and set up machine programs. This is followed by rough machining, fine machining, and second-side machining. The process is wrapped up by completing machining, and 3D inspection. We can produce 200 pieces in 7 days.

Machining Precision: ±0.1mm/100mm

Maximum Part Size: 2000×800×580mm

Materials: Aluminum alloy, titanium alloy, copper (purple luster), stainless steel, zinc alloy, magnesium alloy

Plastic CNC Machining Products

Plastic CNC Product Processing: We fix the raw materials, set up machine programs, rough machine the first side, and fine machine of the first side. Then, we rough machine the second side and fine machine the second side. Finally, we complete machining, conduct manual finishing, and complete both manual inspection and 3D inspection. We can produce 200 sets in 3 days.

Machining Precision: ±0.1mm/100mm

Maximum Part Size: 1780×1180×240mm

Materials: ABS (off-white/black/transparent), PMMA acrylic (colorless transparent / colored transparent / pearl / embossed), bakelite (opaque dark, brown/black), Polycarbonate (PC), PA nylon, PA+ glass fiber, POM (white/black), PP (opalescent)

What are the Common Surface Finish Options?

Surface finishes refer to the process of applying treatments to the surface after the manufacturing process to change the appearance, hardness, surface roughness, and other properties. Common surface finishes for CNC include as-machined, polishing, bead blasting, painting, plating, anodizing, silk screen, and powder coating.

Standard Surface Finishing for Plastic Products

Machining Precision: ±0.05mm/100mm

Surface Finishing Options: Standard surface finishing services for plastics include grinding, polishing, electroplating, wire drawing, spraying painting, laser engraving, and screen printing. Additionally, transparent PMMA and transparent PC finishes can achieve a fully transparent effect by spraying transparent oil. Spraying options include normal gloss and matte oil, spraying with sand, and rubber oil (UV gloss and matte oil, which provides stronger protection).

Standard Surface Finishing for Metal Products

Machining Precision: ±0.05mm/100mm

Surface Finishing Options: Deburring, grinding, polishing, sandblasting, oxidation, electroplating, black oxide, wire drawing, screen printing, laser engraving, spraying metal paint, spraying powder, chromate, spraying rubber paint, heat treatment, passivation, etc.

What are the Benefits and Limitations of Using CNC Machining?

What are the Applications of Our CNC Machining Services?

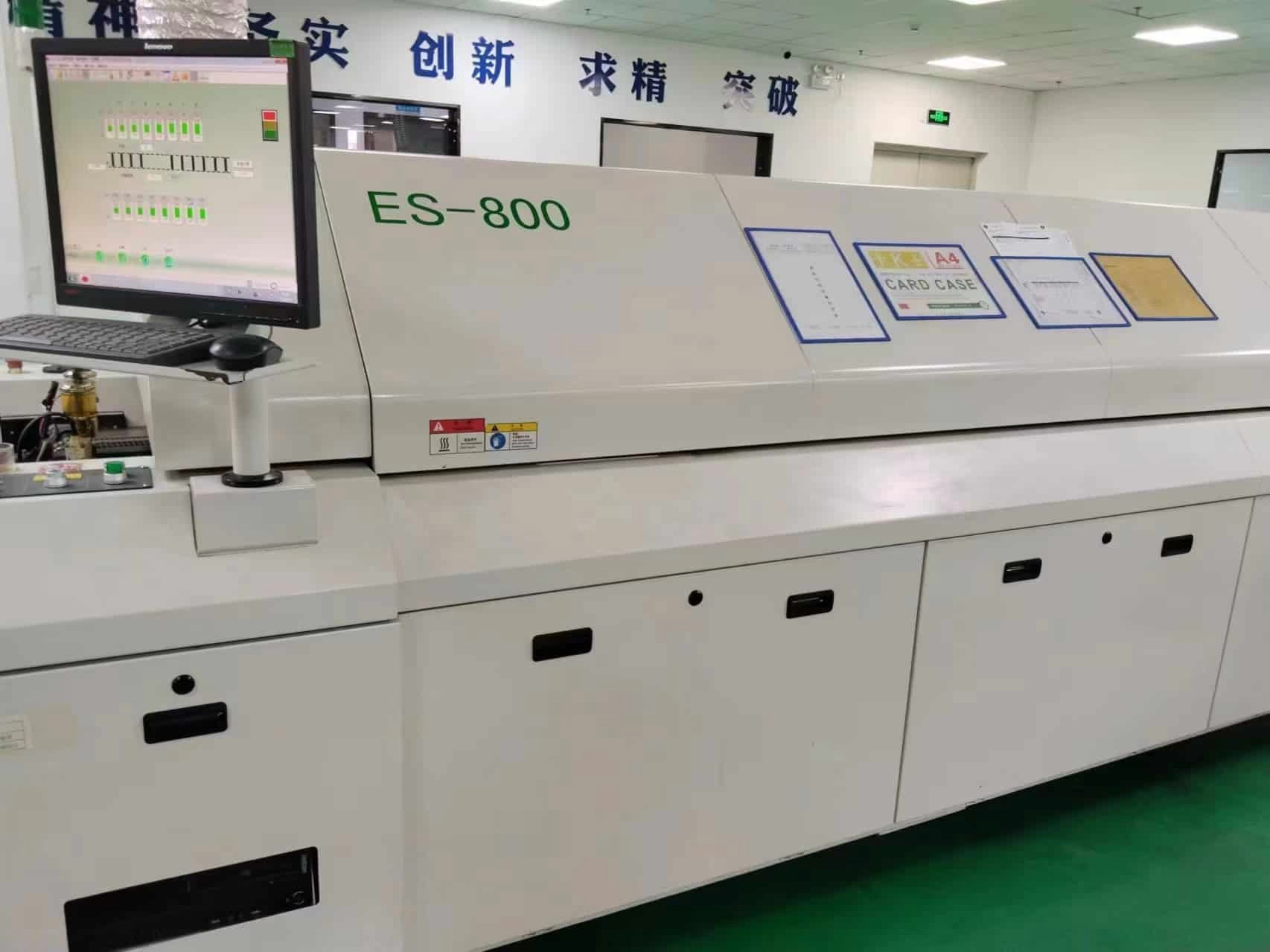

PCB Factory Gallery