PCB & PCB Assembly factory

Welcome to visit our workshop

14-Year PCB Factory

14-Year PCB Factory

PCB Production Capacity:15,000㎡

PCB Production Capacity:15,000㎡

400+ workers

400+ workers

Our factory, established in 2011 and operating across three specialized factories, delivers strong monthly manufacturing capacity—15,000 m² of PCBs, 8,000 flexible circuit boards, and 10,000 fully assembled units.

We offer a diverse portfolio of printed circuit boards, spanning from double-sided layouts all the way up to 30-layer configurations. Our product line encompasses standard PCBs, mid-to-high TG variants, flexible circuits, rigid-flex boards, metal-core substrates, thick copper PCBs, high-frequency boards utilizing materials such as Rogers, F4BM and PTFE, as well as ultra-thin and ultra-thick boards, along with halogen-free options.

In terms of specialized fabrication processes, we provide capabilities including half-hole processing, board bonding, precise impedance control, metal edging treatment, resin via plugging, blue glue application, carbon ink printing, gold finger plating, blind milling, blind and buried via formation, and countersunk hole machining. For surface finish solutions, our offerings cover ENIG (electroless nickel immersion gold), HASL (hot air solder leveling), OSP (organic solderability preservative), ENEPIG (electroless nickel/immersion palladium/immersion gold), heavy gold plating, gold fingers, immersion silver, immersion tin, and the combined ENIG+OSP finish.

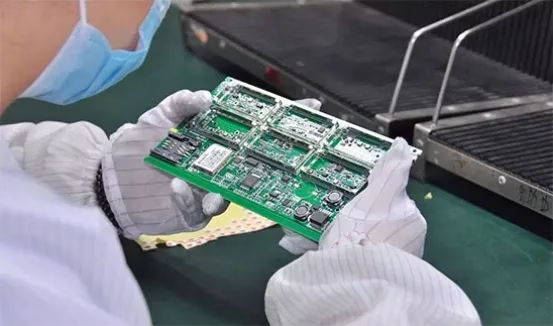

WORKSHOP

Production Lines

Step into our Production Lines

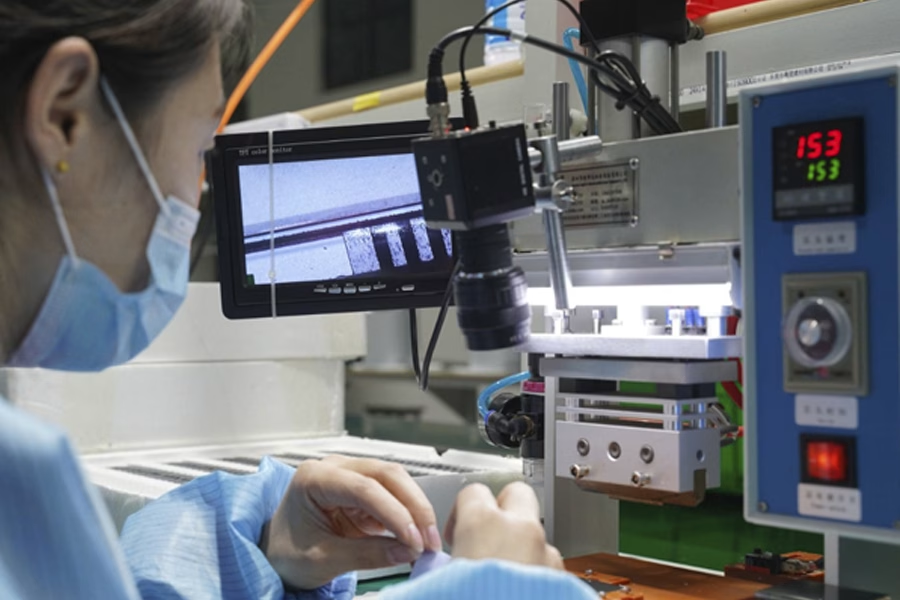

Our equipment

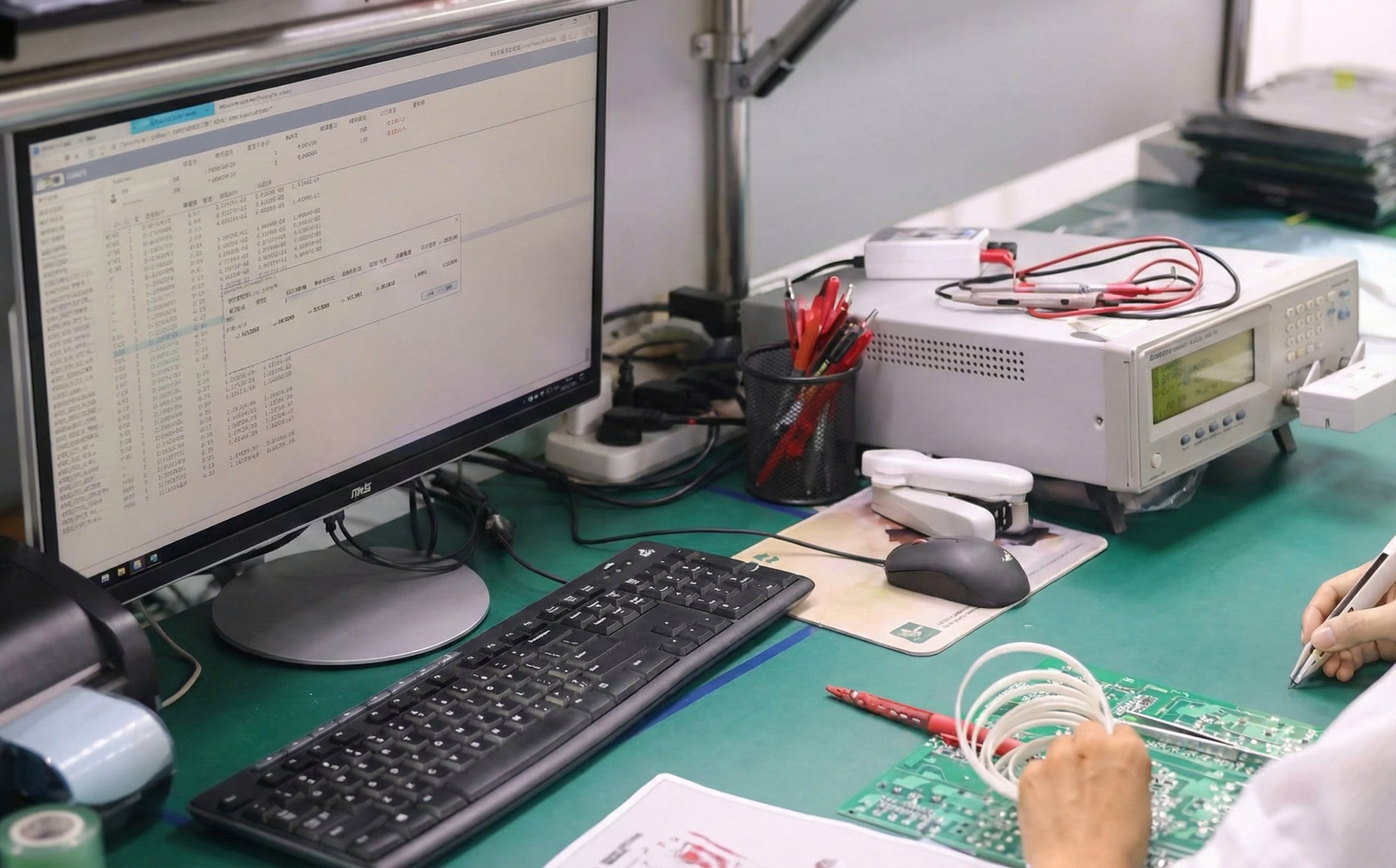

Quality Inspection

We have a complete quality inspection system to ensure that the products we produce are up to standard.