14+

Years Experience

98.15%

On-Time Delivery

96%

customer satisfaction rate

99%

Quality Pass Rate

Need Turnkey PCB Assembly?

PCBAndAssembly is ready to assist from start to finish, including design, fabrication, component sourcing, SMT and through-hole assembly, conformal coating, enclosure, and testing. We handle everything while ensuring quality, efficiency, and a fast turnaround.

We offer both partial and full turnkey PCB assembly services, giving you flexibility based on your needs.

Partial Turnkey

Already have some components? No problem! You can supply specific materials, and we’ll take care of the rest—assembly, quality control, and testing—ensuring a smooth and efficient production process.

Full Turnkey

Want a completely hassle-free experience? We’ll source everything—PCBs, stencils, and components—so you can focus on your design. Just provide us with your Gerber files and specifications, and we’ll handle procurement, assembly, and final testing.

| Type of Turkey Service | Advantages | Ideal Use Cases |

| Partial Turnkey |

|

|

| Full Turnkey |

|

|

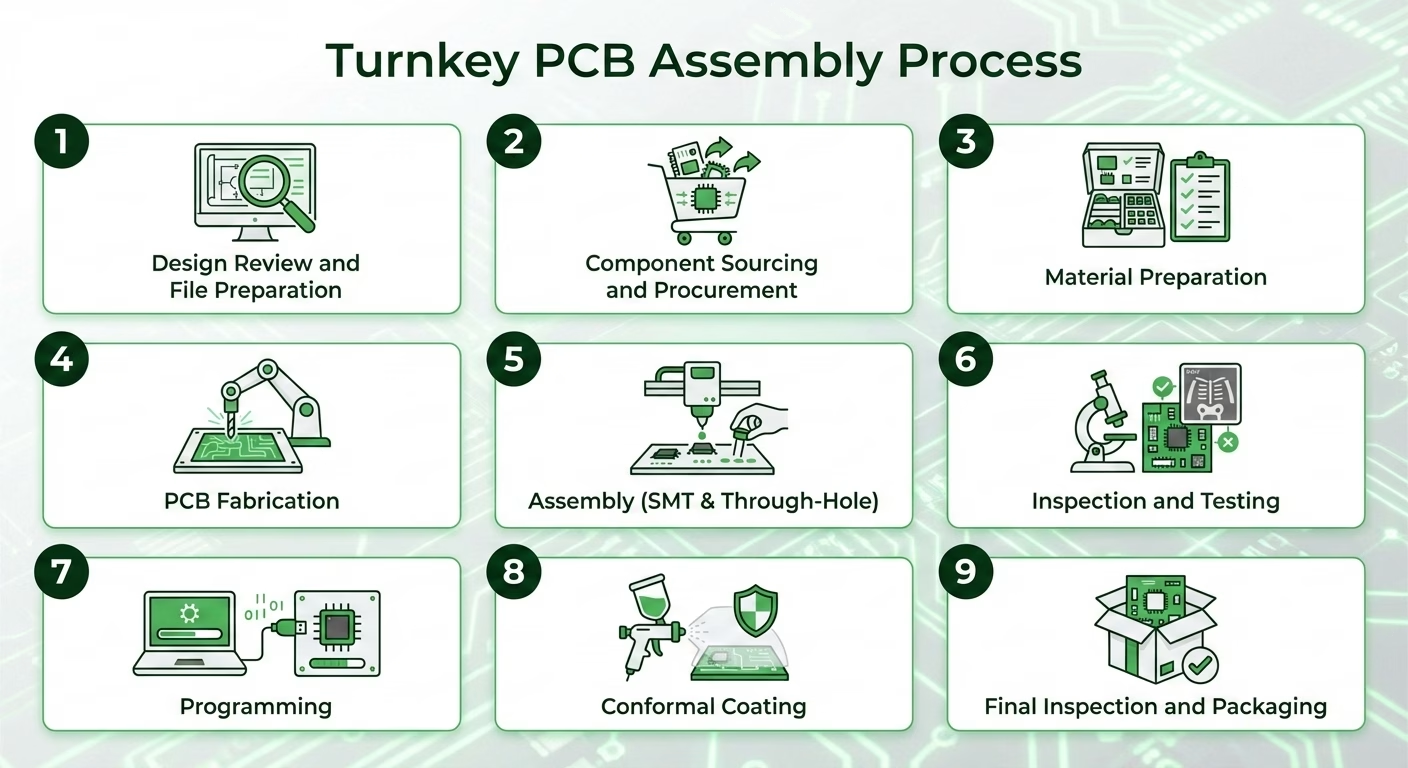

Turnkey PCB Assembly Process

1. Design Review and File Preparation

Before production begins, we conduct Design for Manufacturing (DFM) checks to ensure the PCB is optimized for efficient and cost-effective assembly. We require essential design files, including Gerber, ODB++, BOM, NC drill, and pick-and-place files. A thorough design review helps detect manufacturability issues early, avoiding costly delays.

2. Component Sourcing and Procurement

We handle component sourcing by selecting parts based on the BOM, balancing cost, availability, and lead time. Standard components speed up production, while hard-to-find parts may extend timelines. Our trusted supplier network ensures quality parts at competitive prices, helping reduce procurement risks and costs.

3. Material Preparation

Before assembly, we inspect and verify all components and materials to prevent defects. This includes checking for damage, ensuring part compatibility, and verifying inventory levels. Proper preparation ensures smooth production, reduces rework, and enhances final PCB quality by eliminating material-related issues.

4. PCB Fabrication

Once materials are ready, we begin PCB fabrication, which includes layer stacking, etching, drilling, solder masking, and surface finishing. We also perform quality control checks throughout the process to detect structural or electrical defects. This step ensures the PCB meets design requirements before assembly.

5. Assembly (SMT & Through-Hole)

During assembly, we use Surface Mount Technology (SMT) for high-speed, automated component placement. Through-hole assembly is used for components requiring stronger mechanical bonds. Both methods involve soldering, quality inspections, and reflow processes to ensure secure connections and structural integrity.

6. Inspection and Testing

To maintain high standards, we conduct multiple inspection and testing methods, including AOI, X-ray, ICT, flying probe, and functional testing. These tests identify potential defects before shipment, ensuring reliability, electrical performance, and compliance with industry quality standards.

7. Programming

For PCBs requiring embedded software or firmware, we program microcontrollers, FPGAs, and other ICs to perform their intended functions. Common applications include smart devices, medical equipment, and industrial automation, ensuring seamless integration and device functionality.

8. Conformal Coating

To protect the PCB from moisture, dust, and extreme conditions, we apply a thin conformal coating after assembly. This enhances durability, reduces environmental damage, and extends the PCB’s operational lifespan, especially for harsh environments or mission-critical applications.

9. Final Inspection and Packaging

Before shipping, we perform a final quality check to ensure the PCB is defect-free, fully functional, and meets customer specifications. Boards are packaged in antistatic bags, vacuum-sealed, and moisture-protected to prevent damage in transit, ensuring safe and reliable delivery.

Technical Capabilities

Capabilities & Services

PCB Factory Gallery