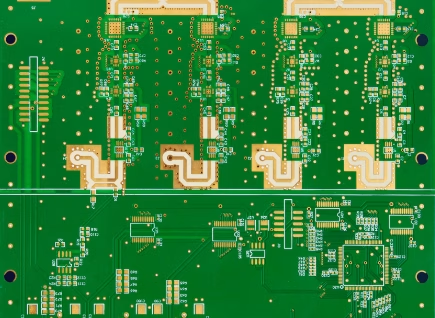

4 Layer PCB Stack-up

A 4 layer PCB stack-up is a circuit board with four conductive layers. It offers a balance of complexity and cost-effectiveness for many electronic designs. PCBAndAssembly specializes in manufacturing high-quality 4 layer PCBs for various industries and applications.

4 Layer PCB Fabrication

The fabrication of 4 layer PCBs starts with core material selection. We use FR-4 or high-frequency laminates based on your needs. The process involves precise layering of copper, prepreg, and core materials. We apply photoresist, expose, and etch the circuit patterns on each layer.

After etching, we laminate the layers together under heat and pressure. This creates a solid board structure. We then drill holes, plate them, and add solder mask and silkscreen. Our advanced equipment ensures accurate alignment and consistent quality throughout production.

Why Choose a 4 Layer PCB Stackup?

A 4 layer PCB stack-up offers a good balance of performance and cost. It’s suitable for many electronic designs that need more complexity than 2 layer boards. Here’s why you might choose a 4 layer PCB:

Improved Signal Integrity

- Dedicated ground and power planes reduce noise

- Better control over impedance and crosstalk

Space Efficiency

- More routing options in a compact form factor

- Ideal for designs with moderate component density

Electromagnetic Compatibility

- Better shielding against EMI

- Reduced emissions for improved product compliance

Design Flexibility

- Allows for mixed-signal designs on a single board

- Supports both through-hole and surface-mount components