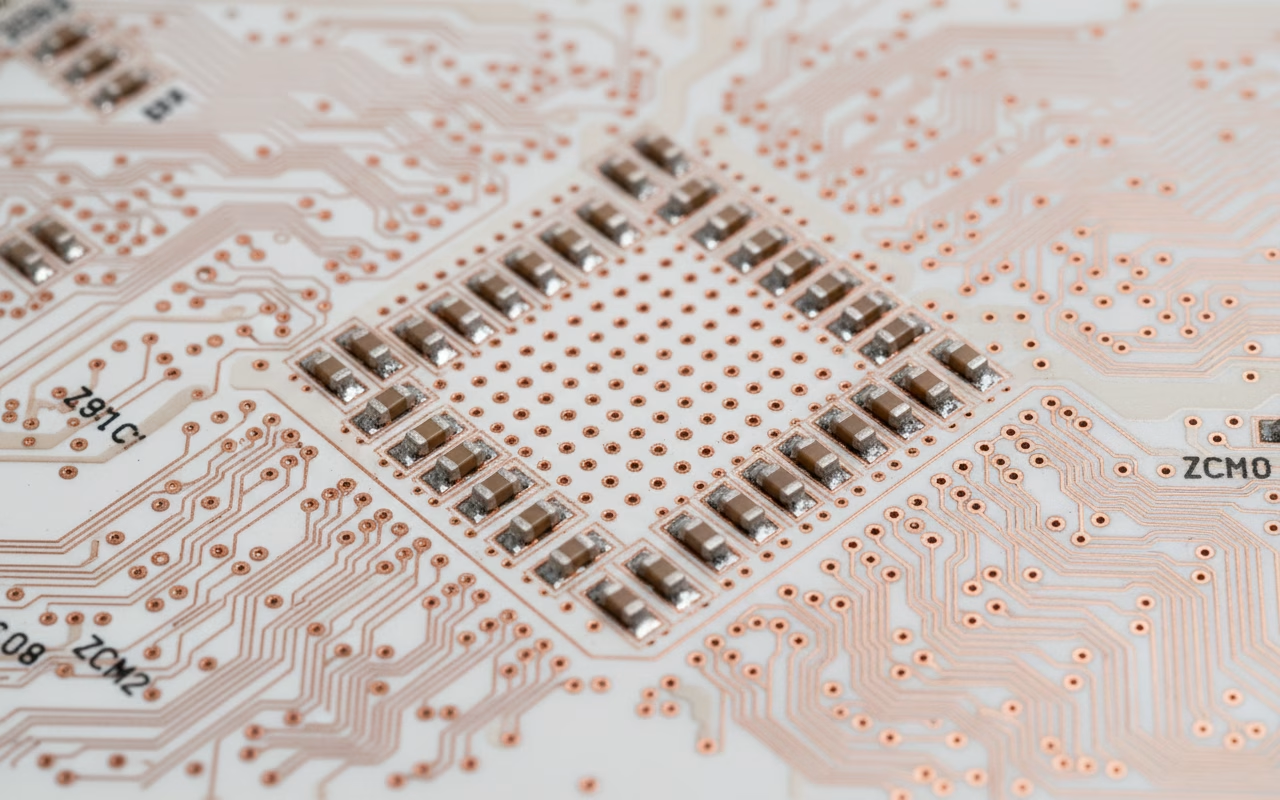

What is a Ceramic PCB?

A ceramic PCB is a high-performance circuit board made from advanced ceramic materials like alumina or aluminum nitride. These materials provide excellent thermal conductivity, efficiently dissipating heat from hotspots and protecting sensitive electronic components from damage.

Why is Ceramic PCB so Popular?

High Thermal Expansion

The first reason why ceramic boards are so popular in the electronics sector is their excellent thermal coefficient of expansion.

It is good to note that the ceramic base heat transmission almost matches silicon and can act as a connection material. Besides, you can use it as an isolator.

For applications requiring exceptional thermal performance, such as high-temperature PCBs, ceramic boards are indispensable due to their adaptability to adverse conditions.

Stability

The application of ceramic brings a stable dielectric capacity, and you can modify the balance into a partial radiofrequency loss to increase your device’s power.

Still, despite the surface roughness, ceramic materials come with an inherent resistance against chemical erosion. Ceramic’s chemical resistance can change to resistance against liquids and moisture.

Versatility

Integrated metal core boards with high thermal expansion can be used for several applications. Using the sintering technique, the metal core can still be turned into a reliable conductor. Therefore, ceramic PCBs’ high processing temperatures make them beneficial.

Durability

The ceramic board fabrication process creates durability through unique properties, such as toughness. That prevents your PCB from wear and tear.

You can be confident that you will not change your PCB soon because of its slow aging capacity. Also, the high thermal resistance of ceramic PCBs makes it assume a decelerated decomposition process.

Adaptability

Lastly, metal cores can serve as inflexible carriers that offer mechanical stiffness. This property makes it easier to use ceramic PCBs in any state of matter because of the high resistance to corrosion and normal wear and tear.