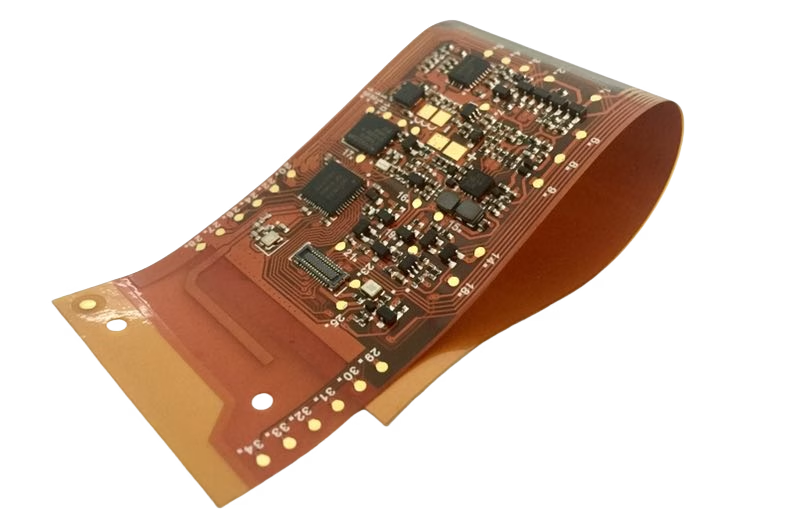

What Is Flexible PCB?

Flexible printed circuit boards, also called Flexible PCBs or Flex PCBs, derive their name for their ability to enable the circuitry to be designed to fit the electronic device or product, as opposed to building the device to conform to the circuit board. Flex boards are characterized by a distinctly patterned printed circuitry and component arrangement highlighted by a malleable base material.

At PCBAndAssembly, we specialize in the fabrication and assembly of flexible PCB products for use in the manufacturing of medical devices and various types of telecommunication and industrial equipment. Our custom PCB manufacturing capabilities allow us to develop and produce a top-performing flex PCB that meets your unique requirements. We can also work with you to produce a custom flex PCB prototype that will significantly improve your prospects of a successful project outcome. For detailed capabilities, please refer to the following form.

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 – 8layers |

| Order Quantity | 1pc – 10000+pcs |

| Build Time | 2days – 5weeks |

| Material | DuPont PI, Domestic Shengyi PI |

| Board Size | Min 6*6mm, Max 406*610mm |

| Board Thickness | 0.1mm – 0.8mm |

| Copper Weight (Finished) | 0.5oz – 2.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating—Soldermask oil | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating—Coverlay | PI and PET film |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL – Hot air solder leveling Lead – free HASL – RoHS ENIG – RoHS Immersion Tin – RoHS OSP – RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 8mil |

| Min. hole size—Drilling (PTH) | 0.2mil |

| Min. hole size—Punching (NPTH) | 0.5mil |

| Tolerance of dimension | ±0.05mm |

| Other Techniques | Peelable solder mask Gold fingers Stiffener (only for PI/FR4 substrate) |

What is the Cost of Flexible PCBs?

On average, flexible PCBs can range from $0.50 to $5.00 per square inch for standard designs and materials. However, this cost is not fixed and can vary based on several factors. The factors that influence the price include necessary assembly labor, prevailing labor rates, and the time required for assembly. Additionally, overhead manufacturing expenses and the design complexity of the board play significant roles in determining the final cost. To get a more accurate cost estimate, please use our free pcb quote form.

How to Reduce PCB Production Costs

- Minimize flexible layers, as rigid laminates are more cost-effective.

- Reduce overall layers to lower the need for additional materials.

- Limit controlled impedance requirements to necessary values only.

- Opt for flexible copper thickness, approximately 1/3 oz.

- Purchase FPCBs in bulk to reduce unit cost.

Why Choose a Flexible PCB Made from China?

China’s flex PCB industry offers many advantages, such as the combination of high quality with cost-effectiveness. Chinese manufacturers like PCBAndAssembly use advanced tech and skilled labor.