What is Halogen free PCB?

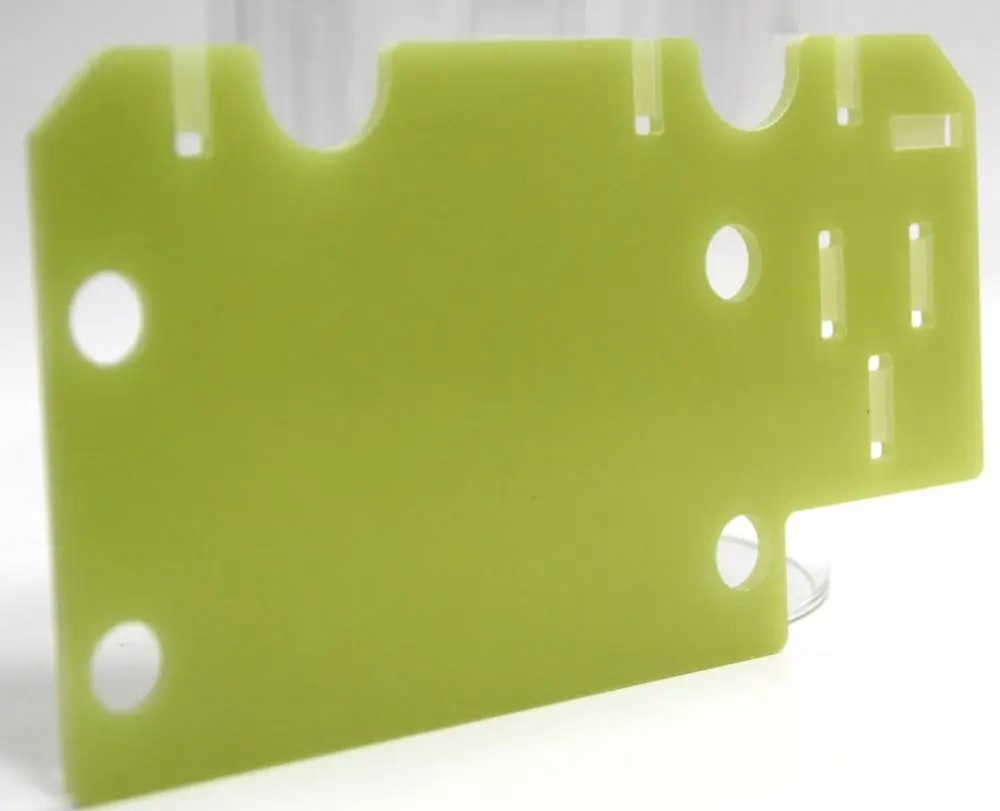

Halogen free PCB is a printed circuit board non-contain any halogen elements, During PCB manufacturing, the concerned halogen elements like Chlorine and Bromine do have some benefits however these do not outweigh their negative impact that can be caused in our day to day life.

What is a Halogen?

Halogens are a class of reactive elements in group 17 on the periodic table.

These elements exhibit high reactivity and are commonly used in many chemical compounds across industries.

Halogen-Free Materials

• Halogen-Free Laminate

In halogen-free PCB, laminate is used for the substrate. Usually, it is halogen-free FR4, where FR stands for flame retardant material. Below are the alternatives for both flame retardant and resin.

Flame Retardants:

Several brominated compounds are used in traditional PCBs, such as PBB, PBDE, TBBPA, and HBCD. In halogen-free printed circuit boards, these compounds are replaced by the following halogen-free flame retardant additives.

• Aluminum (aluminum hydroxide, aluminum diethyl phosphinate)

• Phosphorus (phosphorus-based FR4 materials, phosphorus-based flame retardants)

• Magnesium hydroxide

• Ceramics

• Melamine derivatives

Epoxy Resin:

FR4 halogen-free laminates use epoxy resin. It is typically a thermosetting polymer that provides mechanical stability and insulation. Traditionally, this resin contains halogens. In halogen-free boards, the resins used are usually the following:

• Benzoxazine resin

• Bismaleimide triazine

• trifunctional epoxy resin

• Bisphenol Epoxy Vinyl Ester

• Cyanate

• Polyimide

• Halogen-Free Flux

Halogenated solder paste or flux is used to assemble circuit boards. This solder paste contains a bromine activator and helps remove oxidation during the soldering process while also providing sanding properties. In the halogen-free solder, flux has been replaced by safer options.

Advantages of Halogen-Free PCB

- Environmentally Friendly

- Protect the Health and Safety of Workers

- Improve Circuit Board Insulation

- Lower Water Absorption

- High Thermal Stability

- Improve Market Competitiveness

- Recyclable

Disadvantages of Halogen-Free PCB

- Expensive

- Few Manufacturers

- The Manufacturing Process Is More Inconvenient

As an ISO9001:2000 registered company, we’re one of the most renowned PCB manufacturers in China making a concerted effort to fabricate environmentally friendly custom PCBs that alleviate clients’ concerns. Commonly used substrates for Halogen-free PCB are S1155 (FR4) and S1165 (FR4), the following table lists some parameters of those substrates:

| Material | TG (DSC, °C) |

Td (Wt, °C) |

CTE-z (ppm/°C) |

Td260 (min) |

Td288 (min) |

| S1155(FR4) | 140 | 380 | 41 | 60 | 60 |

| S1165(FR4) | 170 | 360 | 40 | 60 | 15 |

We offer some advanced features for Halogen-free PCB manufacturing service, please refer to below table for comprehensive capabilities:

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 2 – 24layers |

| Order Quantity | 1pc – 10000+pcs |

| Build Time | 2days – 5weeks |

| Material | S1150G, S1165 |

| Board Size | Min 6*6mm | Max 457*610mm |

| Board Thickness | 0.4mm – 6.5mm |

| Copper Weight (Finished) | 0.5oz – 2.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL – Hot Air Solder Leveling Lead Free HASL – RoHS ENIG – Electroless Nickle/Immersion Gold – RoHS Immersion Silver – RoHS Immersion Tin – RoHS OSP – Organic Solderability Preservatives – RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 6mil |

| Other Techniques | Gold fingers Blind/Buried Vias |

For detailed information, please see:《What Is Halogen-Free PCB》