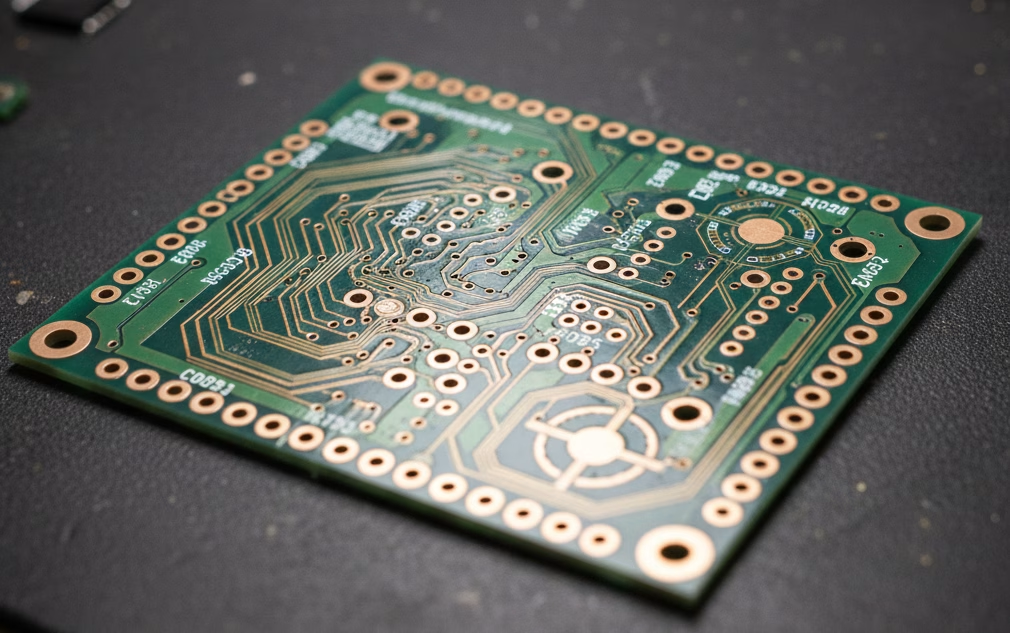

What is High Frequency PCB ?

High-frequency printed circuit boards (PCBs) play a crucial role in various advanced applications, especially in high-frequency PCB communication circuits, where signals operate at frequencies above 1 GHz. These PCBs have specific requirements and parameters that must be carefully considered during the design process to ensure optimal performance in communication systems.

Parameters To Consider For High-Frequency PCB Design:

Frequency Range: High-frequency PCBs typically operate above 1 GHz, with applications in radar systems, military equipment, aerospace, telecommunications, and high-speed digital systems.

Dielectric Constant (Dk): The dielectric constant of the PCB material affects the propagation speed of signals. Lower Dk values are preferred for high-frequency applications to minimize signal distortion and ensure accurate signal transmission.

Dissipation Factor (Df): Df represents the loss of signal energy as it travels through the PCB material. Lower Df values are desirable for high-frequency PCBs to reduce signal attenuation and maintain signal integrity.

Coefficient Of Thermal Expansion (CTE): CTE is crucial for high-frequency PCBs as it impacts the stability of the board’s dimensions under temperature variations. Low CTE materials help prevent issues like warping or delamination.

Signal Integrity: High-frequency PCB designs must minimize signal reflections, crosstalk, and electromagnetic interference (EMI) to preserve signal quality and reliability.

A High-Frequency PCB Requires the Use of Specialized Materials

Special materials are required to achieve the high frequency provided by this type of printed circuit board – any changes in the Er value of these materials can affect the impedance of the board. Many PCB designers turn to Rogers dielectric material for its lower dielectric loss, reduced signal loss, lower cost of circuit fabrication and better suitability for fast-turnaround prototyping applications.

PCBAndAssembly is an experienced full service PCB manufacturer who provides a reliable, superior-performing high-frequency PCB fabrication services.

We manufacture high-frequency PCBs with frequency typically in the range from 500MHz to 2GHz. The following table shows some of our common-use materials for High-Frequency PCBs manufacturing.

| Material | Dielectric Constant |

| RO4350B | 3.48±0.05@10 GHz |

| RO4003C | 3.38±@10 GHz |

| Ro3003 | 3.00±0.04@10 GHz |

| Ro3010 | 10.2±0.03@10 GHz |

| RT5880 | 2.20±0.02@10 GHz |

Check our capabilities by viewing the table found below:

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 2 – 24layers |

| Order Quantity | 1pc – 10000+pcs |

| Build Time | 2days – 5weeks |

| Material | RO4003C, RO4350B, Ro3003, Ro3010, RT5880 |

| PP | Rogers 4450F, Domestic-(25FR), Domestic-(RF-27), Domestic-(6700) |

| Board Size | Min 6mm x 6mm | Max 457mm x 610mm |

| Board Thickness | 0.4mm – 5.0mm |

| Copper Weight(Finished) | 0.5oz – 2.oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | Electroless nickel/immersion gold (ENIG) – RoHS Immersion silver – RoHS Immersion tin – RoHS Organic solderability preservatives – RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 6mil |

| Impedance tolerance | ±10% |

| Other Techniques | Peelable solder mask Gold fingers Carbon oil Countersink holes |