LED PCB Manufacturer

PCBAndAssembly is a leading LED PCB manufacturer, specializing in custom PCB design, fabrication, and assembly for lighting, automotive, and industrial applications. We ensure superior heat management, durability, and energy efficiency, delivering high-quality LED circuit boards with precision and reliability.

14+

Years Experience

98.15%

On-Time Delivery

96%

customer satisfaction rate

99%

Quality Pass Rate

Our LED PCB Customization Capabilities

At PCBAndAssembly, we specialize in custom LED PCBs, tailoring every aspect to meet specific client needs. We offer a range of materials, including FR-4, aluminum, and flexible substrates, carefully selected for their thermal conductivity, durability, and suitability for each application. To enhance LED performance and longevity, we incorporate optimized thermal management features that ensure efficient heat dissipation.

If you have a unique product idea, our experienced engineers provide custom design support, working closely with you to develop prototypes that align with your specifications. Through our rapid prototyping and rigorous testing, we validate designs before mass production, ensuring they meet industry standards and deliver reliable performance.

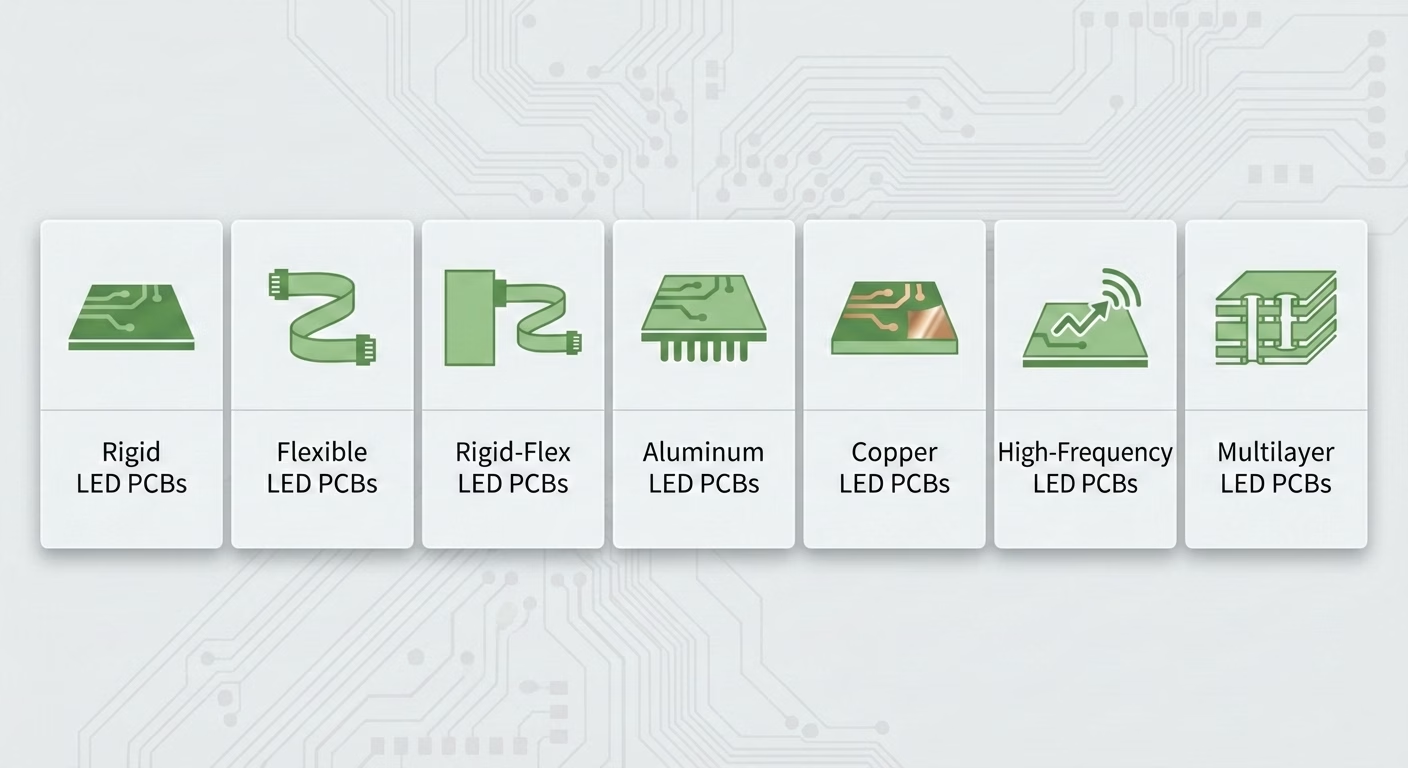

Rigid LED PCBs

Rigid LED PCBs are built from FR-4 material, providing strong structural support for applications where bending is not required. These are commonly used in lighting fixtures, automotive lighting, and electronic devices, offering high-density component placement and reliable performance.

Flexible LED PCBs

Flexible LED PCBs utilize bendable materials, making them ideal for wearable devices, LED strips, and curved lighting where space constraints demand adaptability. Their design versatility allows seamless integration into compact or irregularly shaped products.

Rigid-Flex LED PCBs

Rigid-Flex LED PCBs combine both rigid and flexible layers, making them suitable for medical devices, aerospace applications, and high-end consumer electronics. By reducing interconnects, they save space and improve reliability, especially in dynamic environments.

Aluminum LED PCBs

Aluminum LED PCBs feature an aluminum base layer, enhancing heat dissipation for high-power LED applications such as automotive headlights, industrial lighting, and high-intensity illumination systems. This material extends the lifespan and efficiency of LEDs by preventing overheating.

Copper LED PCBs

Copper LED PCBs offer even higher thermal conductivity than aluminum, making them ideal for high-performance, high-power LED applications that demand superior heat management. These are commonly used in advanced industrial and high-output lighting systems.

High-Frequency LED PCBs

High-Frequency LED PCBs are designed for communication devices and high-speed electronics where minimizing signal loss is critical. These boards ensure signal integrity and reduce electromagnetic interference, making them suitable for high-precision LED applications.

Multilayer LED PCBs

Multilayer LED PCBs consist of multiple conductive layers, enabling complex circuit designs in smart lighting systems and advanced electronic devices. By allowing more components in a compact space, they enhance functionality without increasing size.

PCB Factory Gallery