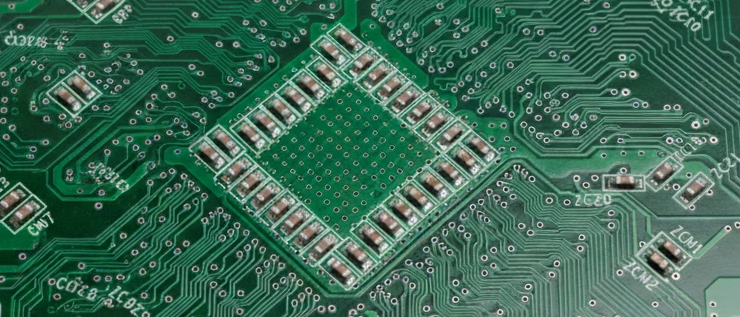

What are Metal Core PCB?

Metal Core PCBs (MCPCBs) are printed circuit boards with a metal base, typically aluminum or copper, for efficient heat dissipation. They improve thermal management, making them ideal for high-power and high-heat applications like LED lighting and power electronics. MCPCBs enhance performance and reliability by reducing heat buildup.

If you’re working on projects that include Passive Infrared (PIR) Sensors, MCPCBs offer excellent thermal performance and are an ideal choice.

| Project Items | OurPCB Capabilities |

| Main Material Suppliers | Shengyi, Quanbao, Xintianyuan, Juding, etc. |

| Metal Types | Copper, Aluminum, Copper-Aluminum Composite, Stainless Steel, Iron |

| Structure | Single-layer, Double-layer/Multilayer, Copper/Aluminum Core, Thermal-Electric Separation |

| Thermal-Electric Separation Flatness | No significant difference(copper core boards) |

| Copper/Aluminum Core Thickness | 0.4–3.2 mm |

| Copper Thickness | (0.33, 0.5, 1, 2, 3, 4, 5, 6) oz, 6–10 oz requires confirmation |

| Insulation Layer Thickness | Thermal conductive insulation: 50, 75, 100, 125, 150 μm Others: FR4 bonding sheets |

| Thermal Conductivity | Standard FR4, 1 W/m·K, 2 W/m·K, 3 W/m·K, up to 15 W/m·K |

| Max Finshed Board Size – excl. Cu Core & Thermal-Electric Separation | 22.5″ × 30″ |

| PTH | Copper Base Thickness <0.8 mm: 0.8–6.0 mm Copper Base Thickness 0.8–1.6 mm: 1.0–8.0 mm Copper Base Thickness 1.7–3.2 mm: 1.2–8.0 mm |

| Countersink Holes | Vertical angle: 90° ± 5° Min drill bit: 0.8 ± 0.15 mm, Can be enlarged if needed Depth tolerance: ±0.20 mm |

| Counterbore Holes | Min angle: 30° ± 5°, Max angle: 180° Min drill bit: 0.8 ± 0.15 mm, Max drill bit: 6.0 ± 0.15 mm Depth tolerance: ±0.20 mm |