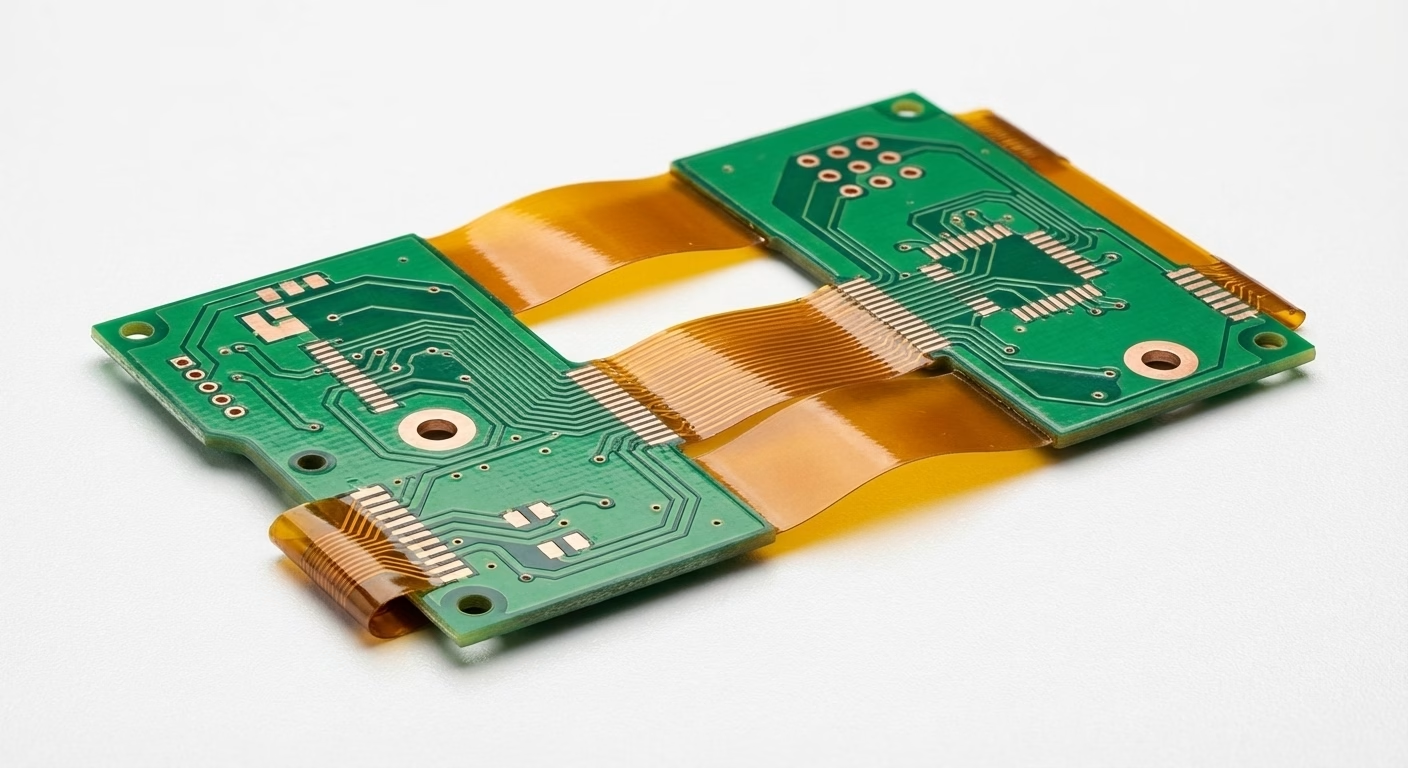

What is Rigid-Flex PCB?

Rigid-flex PCBs are a hybrid circuit board combining components of rigid and flexible PCBs, and are used to connect electronic components in a variety of both consumer and non-consumer devices. This board type can be folded or flexed continuously on the flexible section, which usually joins two rigid parts.

Our Rigid-Flex PCB Manufacturing Capabilities

| feature | ability |

| Number of layers | 2-32 |

| quantity | 1-10000+ |

| quality level | Standard IPC 2 |

| Build time | 2-20 days |

| Request Quote | 1-2 days |

| Material | DuPont, Fr4, polyimide |

| Board size | Minimum 6*6mm

Maximum 457*610mm |

| Plate thickness | 0.6-2mm |

| Copper thickness | 0.5-2 oz |

| Surface treatment | Lead-free HASL – RoHS, immersion gold, electroplating gold, IM-Ag, electroplating silver, HASL |

| Drilling accuracy | +/-0.05mm |

| Other technologies | HDI gold finger reinforcement board (only suitable for PI/FR4 substrate) |

Disadvantages of Rigid-Flex PCB

Despite its advantages, rigid-flex PCB also has some drawbacks:

- High Production Complexity

The process of combining flexible and rigid materials is more complex than manufacturing purely rigid or flexible boards. This complexity can lead to longer production times and increased costs. - High Design Requirements

Designing a rigid-flex PCB requires precise planning, especially when considering flexible section bending radii, stress concentrations, and thermal management. Poor design can lead to reduced board performance or failure.

Design Issues and Considerations for Rigid-Flex PCB

- Design Specifications and Requirements

It is essential to adhere to strict design specifications when creating a rigid-flex PCB. Ensure that the bending radius of the flexible sections meets manufacturing requirements to prevent material damage or board failure. - Stress Concentration and Thermal Management

Special attention should be paid to stress concentration issues in the design. Use appropriate transition areas and reinforcement structures in bending regions to minimize stress concentrations. Additionally, consider thermal management to ensure effective heat dissipation, preventing board failure due to overheating. - Circuit Layout and Routing

When laying out the circuit, carefully plan the routing for both rigid and flexible areas. Avoid high-frequency signals and high-power circuits in flexible sections to minimize electromagnetic interference and signal integrity issues. - Connections and Soldering Techniques

The connection and soldering techniques for rigid-flex PCBs are critical. Use suitable soldering technologies to ensure reliable connections between rigid and flexible parts. Consider potential damage to flexible sections during soldering and choose appropriate materials and processes. - Material Selection

Selecting the right materials is crucial for the performance of rigid-flex PCBs. Typically, rigid sections use traditional FR-4 materials, while flexible sections use high-performance polyimide (PI) materials or other flexible circuit board materials. Ensure material compatibility to guarantee overall board stability and reliability.

Disadvantages of Rigid-Flex PCB

Despite its advantages, rigid-flex PCB also has some drawbacks:

- High Production Complexity

The process of combining flexible and rigid materials is more complex than manufacturing purely rigid or flexible boards. This complexity can lead to longer production times and increased costs. - High Design Requirements

Designing a rigid-flex PCB requires precise planning, especially when considering flexible section bending radii, stress concentrations, and thermal management. Poor design can lead to reduced board performance or failure.

PCBAndAssembly provides high-quality rigid-flex PCB manufacturing and assembly services. Rigid-flex PCBs combine flexible and rigid layers, offering durability and space efficiency for complex electronic designs. We ensure precision engineering, strict quality control, and fast turnaround times to meet your requirements.