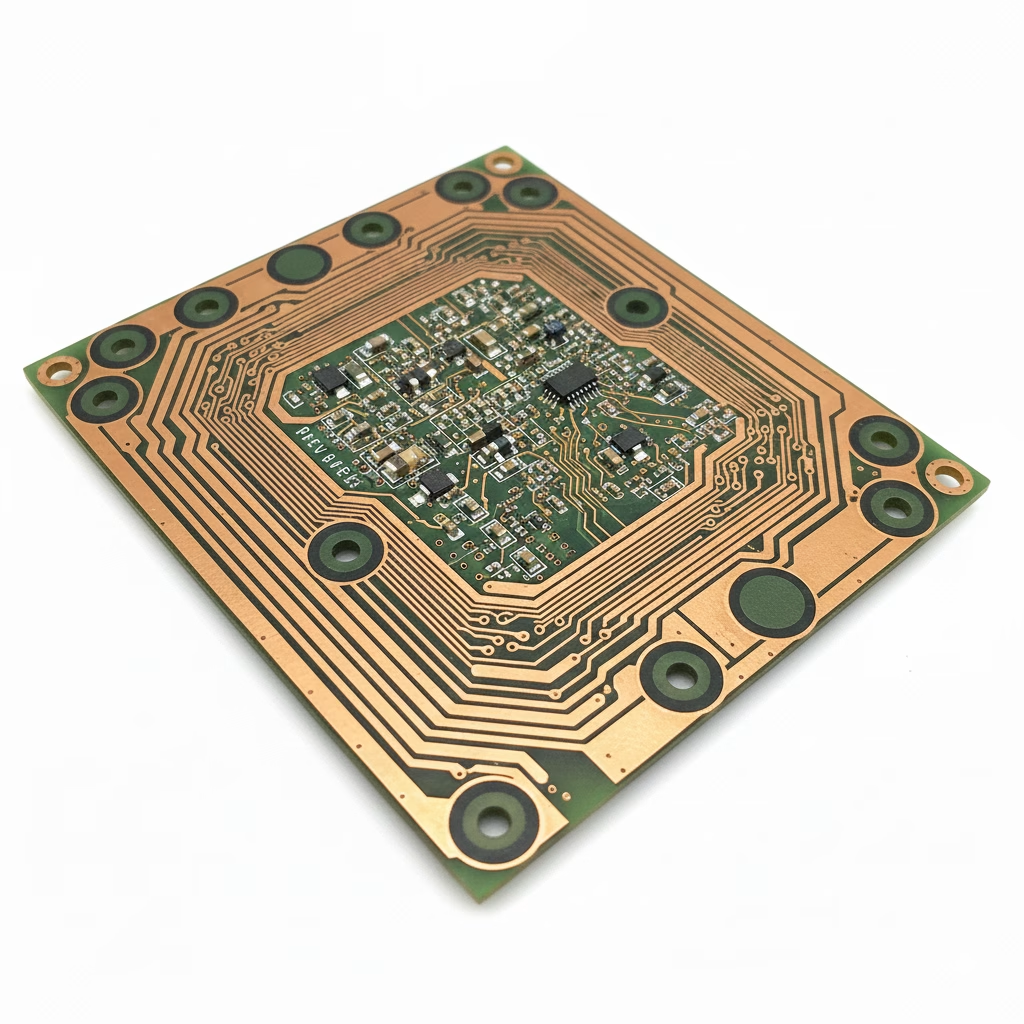

What Is Heavy Copper PCB?

Heavy Copper PCB, as the name suggests, is a printed circuit board with thicker copper layers compared to standard PCBs. Typically, the copper layer thickness in standard PCBs ranges from 1oz to 2oz, while in Heavy Copper PCBs, the copper layer thickness can exceed 3oz. This technology provides improved current-carrying capacity and mechanical strength, making it widely used in high-voltage, high-current, and extreme environment electronic products.

Why Use Heavy Copper PCB?

Copper is a material with high electrical conductivity (58.5 MS/m) and low resistance (1.68 μΩ·cm).

Standard PCBs often fail under high-stress conditions. Engineers choose Heavy Copper primarily to bridge the gap between complex circuitry and extreme power demands.

Advantages of Heavy Copper PCB

Enhanced Reliability of Electronic Components

- High Thermal and Electrical Conductivity: Heavy Copper PCBs offer excellent thermal and electrical conductivity, effectively dissipating and conducting heat to prevent component burnout due to heat concentration.

- Applications: Suitable for power management systems, high-power LEDs, industrial control systems, and automotive electronics where high reliability is required.

Corrosion Resistance

- Protective Layer: Heavy Copper PCBs can form a thin layer of copper oxide in the air, providing additional corrosion protection and extending the PCB’s service life.

- Applications: Ideal for devices exposed to harsh environments, such as outdoor electrical equipment, marine equipment, and chemical equipment.

High Temperature Resistance and Thermal Stability

- Stability: Heavy Copper PCBs maintain their physical and chemical properties in high-temperature environments and are not prone to decomposition or damage.

- Applications: Suitable for applications in high-temperature environments, such as aerospace equipment, electric vehicle battery management systems, and high-power amplifiers.

Efficient Signal Transmission

- Low Resistivity: Using Heavy Copper as the conductive layer provides low resistivity and excellent conductivity, enabling high-speed signal transmission and reducing signal loss.

- Applications: Suitable for high-speed communication equipment, server motherboards, and high-frequency RF applications.

Electromagnetic Shielding

- Superior Shielding Performance: Heavy Copper PCBs have excellent electromagnetic shielding capabilities. Their high conductivity allows them to effectively reflect and absorb electromagnetic waves, reducing electromagnetic interference (EMI).

- Applications: Ideal for devices sensitive to electromagnetic interference, such as medical equipment, communication devices, and precision measurement instruments.

Machinability and High Mechanical Strength

- Ease of Processing: Heavy Copper has good ductility and flexibility, making it easy to process into various shapes and sizes.

- High Mechanical Strength: Heavy Copper PCBs provide sufficient mechanical strength, offering good physical protection and preventing damage during operation and use.

- Applications: Suitable for applications requiring high mechanical strength and complex structures, such as military equipment, heavy machinery, and large industrial equipment.

Copper PCB Manufacturing Capabilities Table

PCBAndAssembly is a highly skilled PCB manufacturer that can develop and produce a superior thick copper PCB product of the highest quality. We offer a thick copper PCB manufacturing service that uses copper weights of up to 15oz (525μm). Check our capabilities in the following table:

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 2 – 24layers |

| Order Quantity | 1pc – 10000+pcs |

| Build Time | 2days – 5weeks |

| Material | FR-4 Standard Tg 140°C, FR4-High Tg 170°C |

| Board Size | Min 6mm x 6mm | Max 457mm x 610mm |

| Board Thickness | 0.6mm – 6.5mm |

| Max Outer Layer Copper Weight (Finished) | 15oz |

| Max Inner Layer Copper Weight | 12oz |

| Min Tracing/Spacing | For External layers: 4oz Cu 9mil/9mil 5oz Cu 11mil/11mil 6oz Cu 13mil/13mil 12oz Cu 20mil/32mil 15oz Cu 32mil/40milFor Internal layers: 4oz Cu 8mil/12mil 5oz Cu 10mil/14mil 6oz Cu 12mil/16mil 12oz Cu 20mil/32mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL – Hot Air Solder Leveling Lead Free HASL – RoHS ENIG – Electroless Nickle/Immersion Gold – RoHS |

| Min Annular Ring | 6mil |

| Min Drilling Hole Diameter | 10mil |

| Other Techniques | Gold fingers Blind/Buried Vias |