Why Are Circuit Boards Green?

Circuit boards are typically green due to the green solder mask, which aids in visual inspection and was popularized by U.S. military standards. This color remains the industry standard because it offers excellent contrast during manufacturing and inspection processes, though other colors are available. PCBAndAssembly provides expert PCB manufacturing services, offering both traditional green boards and custom color options. Trust our experience to deliver high-quality boards that meet your specific needs.

Get Your PCB Quote!

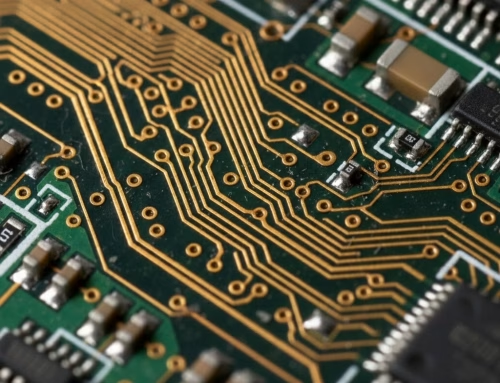

Open almost any electronic device today – a smartphone, a computer , a remote control – and you’re highly likely to find a familiar sight: a printed circuit board (PCB) with a distinctive green hue. This isn’t a mere aesthetic preference or a random design choice; the dominance of green in the world of circuit boards is a fascinating story deeply rooted in practical advantages, historical precedent, and technological evolution. Far from being arbitrary, the iconic green color is the result of a deliberate blend of factors that have made it the enduring industry standard.

But why exactly is this the case? What specific characteristics make green the preferred color for PCBs, and how did this tradition solidify in modern electronics manufacturing?

1. The Solder Mask: The True Source of Green

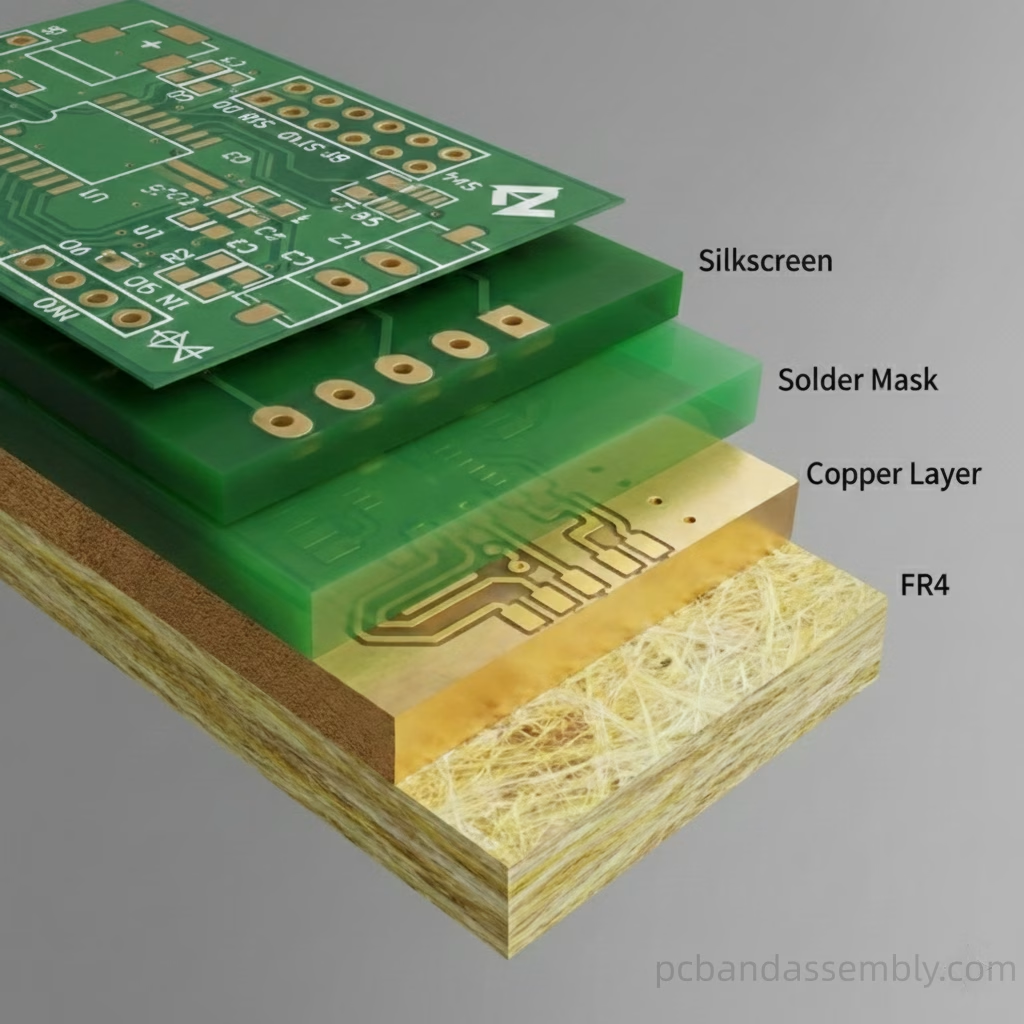

To truly understand why circuit boards are green, we must first understand the role of the solder mask. A PCB fundamentally starts as a tan or yellowish fiberglass sheet, onto which conductive copper traces are etched to connect various electronic components. However, bare copper is susceptible to corrosion, accidental short circuits, and damage during the manufacturing process, particularly during soldering.

This is where the solder mask comes in. It’s a protective layer, typically a polymer coating, that is applied over the copper traces but leaves exposed pads where components will be soldered. This layer acts as an “armor” for the delicate circuitry underneath, preventing dirt, moisture, and accidental metal contact from causing issues. It also plays a crucial role during the automated soldering process, preventing solder bridges (unwanted electrical connections) between closely spaced pads.

The green color that we associate with PCBs actually comes from this solder mask layer, not the underlying fiberglass or copper. “The green color mainly comes from the solder mask, which helps protect the delicate copper circuits underneath from air and errors during soldering.” Early protection experiments involved various coatings, but the specific chemical compounds used in the green solder mask proved to be incredibly tough, able to withstand high soldering temperatures and harsh manufacturing chemicals. This established green as a reliable and effective protective coating.

2. Historical Reasons

The choice of green as the predominant PCB color wasn’t a sudden mandate but rather an evolution driven by several historical factors that contributed to it becoming an industry standard:

- Early Adoption and Consistency:In the nascent days of electronics, manufacturers experimented with various colors for solder masks. However, one specific green pigment likely emerged as the most stable, reliable, and cost- effective option for the protective resin. As one successful company adopted it, others followed suit, leading to a de facto standard. This consistency allowed for streamlined manufacturing processes and material sourcing across the industry.

- Military Influence (Limited):While not the sole reason, there’s a theory that military standards in the mid-20th century may have played a minor role. Green is a color often associated with military equipment due to its cam ouflaging properties and historical use in various applications. Some early military specifications might have subtly influenced the preference, though its primary drivers were more broadly practical.

- Supplier Consolidation:Over time, as fewer chemical suppliers dominated the market for solder mask resins, the most popular and readily available option was often green. This further cemented its status, as it became the easiest and most economical material to acquire for PCB manufacturing.

The cumulative effect of these factors meant that green wasn’t just a color; it was a proven solution that worked consistently across diverse applications and manufacturing environments.

3. The Ergonomic Advantage

Beyond history and protection , green offers significant ergonomic and practical advantages, particularly for human operators involved in PCB assembly and inspection. These benefits contribute greatly to efficiency and accuracy:

Enhanced Visibility and Contrast

Green solder mask provides an excellent balance of contrast. The bright white silkscreen legends (text and symbols), the silver-colored solder pads, and the various component colors (black, grey, tan) all stand out prominently against a green background. This high contrast makes it easier for technicians to:

- Identify Components:Quickly read part numbers, polarity markings, and orientation guides printed on the board.

- Trace Pathways:Vis ually follow the copper traces, which often have a slightly different sheen or shade under the translucent solder mask, aiding in debugging and inspection.

- Spot Defects:Crucially, green offers superior defect detection. Manufacturing flaws like stray copper, solder bridges, cold solder joints, or missing components are much more apparent against a neutral green backdrop compared to other colors.

This clear distinction is vital in the intricate world of electronics, where even microscopic errors can lead to device failure.

Reduced Eye Strain and Improved Eye Comfort

Human eyes are most sensitive to the green spectrum of light. This means that green is perceived brightly and clearly without causing undue strain. When technicians spend hours examining PCBs under microscopes or with magnifying lamps, working with a color that is easy on the eyes becomes incredibly important. Red or blue boards, for example, might be visually striking but can lead to faster eye fatigue, reduced productivity, and an increased likelihood of errors. The soothing nature of green helps maintain focus and reduce visual stress over long periods.

4. The Economic Edge

Cost-effectiveness is another paramount reason why green remains king. In mass production, even minor cost differences per unit can lead to significant savings when scaled across millions of devices. The green solder mask is typically the most affordable option for several reasons:

- Volume Manufacturing:Because green is the most common color, it is produced in the largest quantities by chemical manufacturers. This high volume drives down the per-unit cost of the raw materials (the resin and pigment).

- Standardization:Manufacturing facilities often have their equipment and processes optimized for green solder mask. Switching to other colors might require changes in curing times, exposure levels, or cleaning agents, potentially increasing setup costs and production time.

- Material Availability:Green solder mask is always readily available. For PCB manufacturers, this means shorter lead times, fewer inventory headaches , and less risk of production delays due to material shortages. This reliability contributes to overall lower manufacturing costs.

For high-volume electronics, where profit margins can be razor-thin, choosing the most economical and efficient option is a business imperative, and green consistently delivers on this front.

5. A Spectrum of Solder Mask Colors

While green dominates, it’s important to note that other solder mask colors are available and are used for specific applications or aesthetic preferences. Common alternatives include red, blue, black, white, and even yellow:

| Color | Pros | Cons | Typical Use Cases |

| Red | Good contrast with traces, visually distinct. | Can be harder to read silkscreen; hides some defects. | Prototyping, hobbyist boards, brand differentiation. |

| Blue | Popular for specific types of boards (e.g., Arduino); good contrast. | Less contrast for traces than green; shows dust. | Educational kits, certain niche products. |

| Black | Sleek, premium look; good for high-end devices. | Difficult to see traces/defects; poor contrast for silkscreen. | High-end consumer electronics (often with gold /silver finish). |

| White | Excellent contrast for black silkscreen. | Very difficult to see traces and some defects. | LED lighting products (reflects light). |

| Yellow | Good for antique/retro look. | Less common, similar issues to white/red for inspection. | Specialty, aesthetic purposes. |

Each color has its trade -offs. Black and white, for instance, are notoriously difficult for optical inspection systems and human eyes to pick out fine details or spotting problems, making them less ideal for complex, high-reliability boards. Red and blue offer decent contrast but typically don’t match green’s overall balance of visibility, eye comfort, and cost.

6.FAQs on Why are Circuit Boards Green?

The base material (fiberglass, FR-4) is typically tan or yellowish. The green color comes from the protective solder mask applied over the copper traces.

Generally, yes. Due to high volume production and standardization, green solder mask materials are typically the most cost-effective option for PCB manufacturing.

While green, red, blue, black, and white are common, custom colors are possible, though they may incur higher costs and longer lead times due to less common pigments and specialized production runs.

No, the color of the solder mask has no impact on the electrical performance or functionality of the circuit board itself. It’s purely for protection, visibility, and aesthetics.

7. Summary

The green color of most printed circuit boards is far from a random choice. It’s a testament to the confluence of historical development, practical manufacturing advantages, ergonomic benefits for human inspection, and undeniable cost-effectiveness. The green solder mask acts as a vital protective layer, shields delicate components, facilitates easy visual inspection of PCB boards, and minimizes eye strain for technicians. As an established industry standard, green continues to be the logical choice for the vast majority of electronic devices, blending functionality with efficiency in the intricate world of electronics manufacturing.

Key Takeaways

- The green color of circuit boards comes from the protective solder masklayer, not the base material.

- Green became the industry standarddue to a mix of historical reasons, including early reliability and mass adoption.

- Its primary benefit is ergonomic, offering excellent contrast for components and traces, reducing eye strainfor inspectors.

- Green facilitates superior defect detection, making manufacturing flaws more visible.

- It is consistently the most cost-effectiveoption due to high-volume production and standardization .

While other PCB colors exist (red, blue, black), they often present trade-offs in visibility or cost compared to green.

Get Your PCB Quote!