Shenzhen SMT Patch Processing Technology

Get Your PCB Quote!

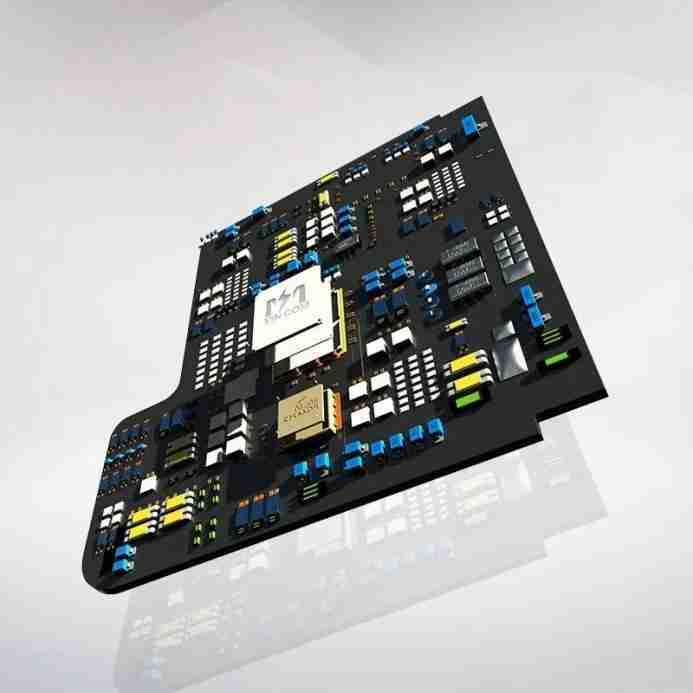

SMT is the most popular processing technology in the current electronic assembly industry. It can save costs and time to a great extent and improve production efficiency. This processing technology has been used in the processing plant of pcbandassembly Technology. SMT can be divided into single-sided and double-sided patch processing technologies, and can also be divided into assembly and mixed assembly. Today, I will show you how to do it.

Single-Sided Assembly:

Incoming material inspection → Screen printing solder paste (apply SMD glue) → SMD → Drying (curing) → Reflow soldering → Cleaning → Inspection → Rework

Double-Sided Assembly:

A: Incoming material inspection → Screen printing solder paste (apply SMD glue) on PCB A side → Screen printing solder paste (apply SMD glue) on PCB B side → SMD → Drying → Reflow soldering (preferably only on B side → Cleaning → Inspection → Rework).

B: Incoming material inspection → Screen printing solder paste (apply SMD glue) on PCB A side → SMD → Drying (curing) → Reflow soldering on A side → Cleaning → Flip board → Apply SMD glue on PCB B side → SMD → Curing → Wave soldering on B side → Cleaning → Inspection → Rework.

This processing technology is suitable for reflow soldering on the PCB A side and wave soldering on the B side. This processing technology is suitable for SMDs assembled on the PCB B side when there are only SOT or SOIC (28) pins or less.

Single-Sided Mixed Assembly:

Incoming material inspection → Screen printing solder paste on PCB A side (applying SMD glue) → SMD → Drying (curing) → Reflow soldering → Cleaning → Insertion → Wave soldering → Cleaning → Inspection → Rework

Double-sided mixed assembly:

A: Incoming material inspection → Apply SMD glue on PCB B side → SMD → Curing → Flip board → Insertion on PCB A side → Wave soldering → Cleaning → Inspection → Rework

Apply first and then insert, suitable for the situation where there are more SMD components than discrete components

B: Incoming material inspection → PCB A Surface plug-in (pin bending) → flip board → PCB B surface SMD glue → SMD → curing → flip board → wave soldering → cleaning → inspection → rework

Plug in first and then stick, suitable for the situation where there are more discrete components than SMD components

C: Incoming material inspection → PCB A surface screen printing solder paste → SMD → drying → reflow soldering → plugin, pin bending → flip board → PCB B surface SMD glue → SMD → curing → flip board → wave soldering → cleaning → inspection → rework A surface mixed, B surface mounting.

D: Incoming material inspection → PCB B surface SMD glue → SMD → curing → flip board → PCB A surface screen printing solder paste → SMD → A surface reflow soldering → plugin → B surface wave soldering → cleaning → inspection → rework A surface mixed, B surface mounting. First, paste SMD on both sides, reflow soldering, then insert and wave soldering

E: Incoming material inspection => PCB B side screen printing solder paste (apply SMD glue) → SMD → drying (curing) → reflow soldering → (local soldering can be used) → plug-in → wave soldering 2 (if there are few insert components, manual soldering can be used) → cleaning → inspection → rework A side mounting, B side mixed assembly.

The above is the single-sided and double-sided patch process of Shenzhen SMT processing. You are welcome to contact pcbandassembly Prototyping at any time and visit the factory for consultation. Pcbandassembly has 6 years of SMT processing experience in Shenzhen, with high product quality and fast delivery.

Shenzhen pcbandassembly, a long-established electronic processing factory in Shenzhen, can provide SMT processing services. It also has rich experience in PCBA processing. PCBA is a one-stop service for you. pcbandassembly can also undertake DIP plug-in processing, PCB production, and electronic circuit board manufacturing services.