Robotics PCBA and Industrial Control PCBA Guide

Robotics PCBA and industrial control PCBA are the foundational electronic components that enable the sophisticated functionality of modern advanced technology.

Get Your PCB Quote!

Table of Contents

1. Introduction: The Foundation of Modern Automation

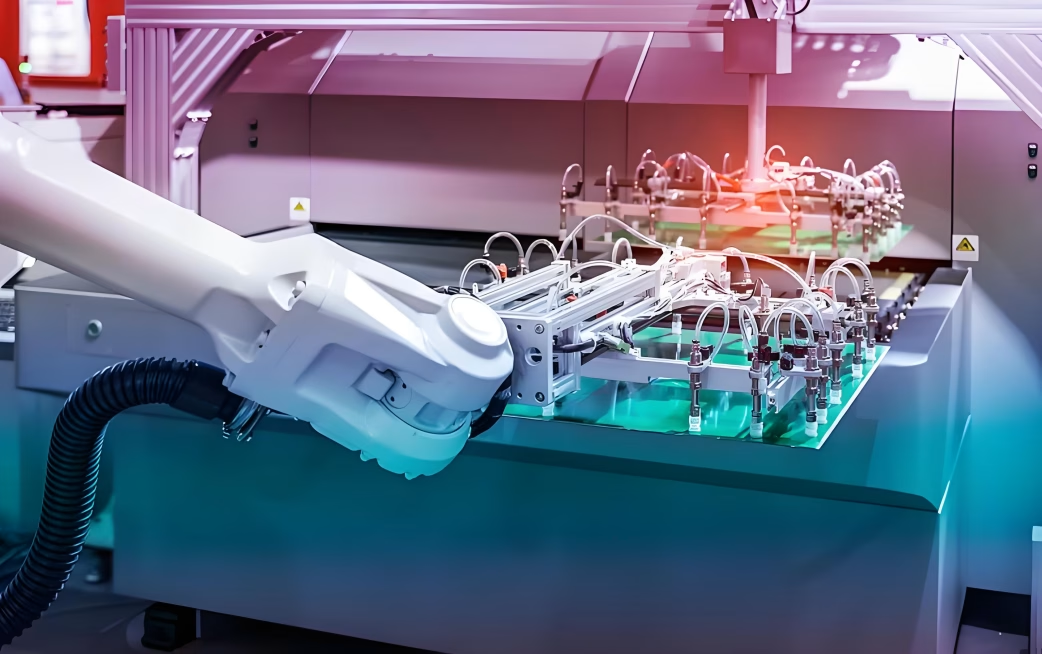

In the rapidly advancing world of automation, robotics, and industrial control, the Printed Circuit Board Assembly (PCBA) stands as the silent hero, the intricate brain behind every precise movement and intelligent decision. From the collaborative robots on manufacturing lines to the sophisticated control systems managing vast industrial processes, reliable and high-performance PCBAs are absolutely critical. As industries embrace Industry 4.0 and integrate Artificial Intelligence (AI) into their operations, the demand for increasingly complex, robust, and miniaturized PCB assembly grows exponentially. This article delves into the pivotal role of robotics PCBA and industrial control PCBA, exploring the unique challenges, technological advancements, and the transformative impact of AI on these essential components.

2. The Indispensable Role of Robotics PCBA

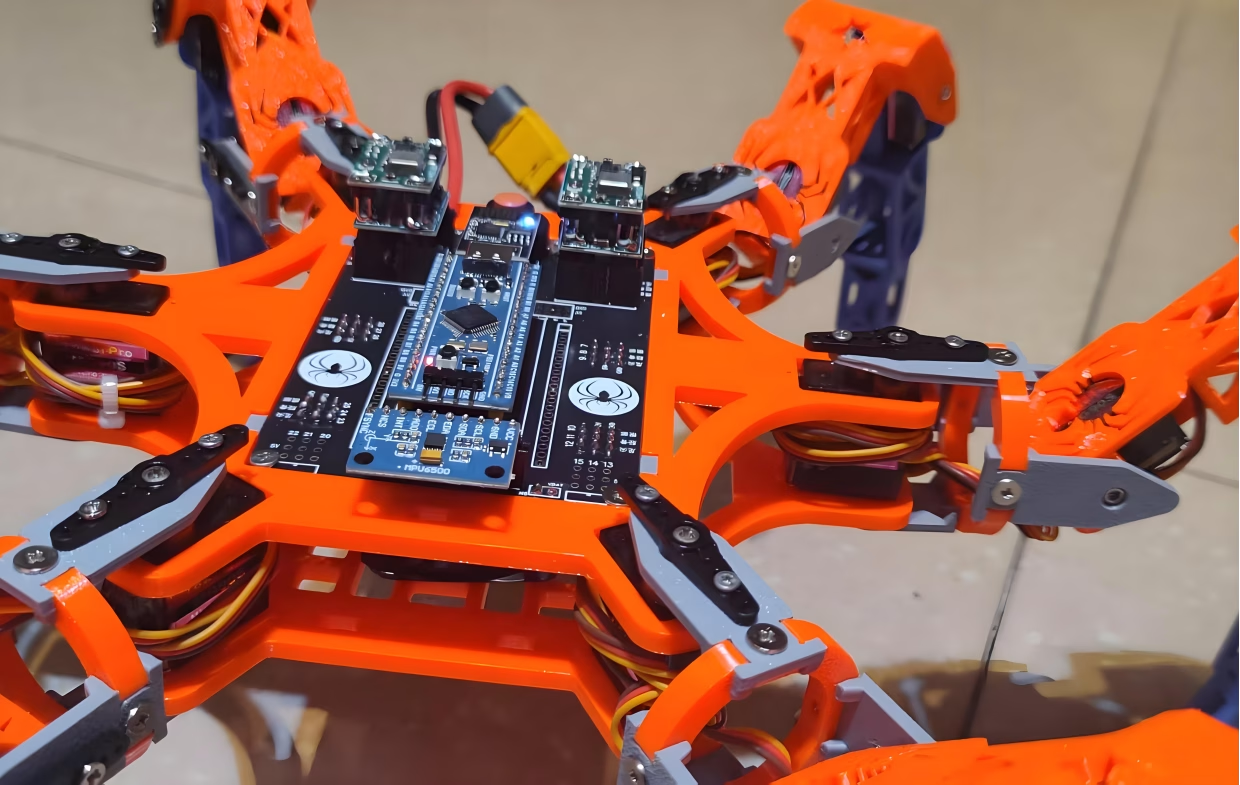

Robots, whether industrial manipulators, autonomous mobile robots (AMRs), or highly specialized service robots, are essentially complex electronic systems housed in mechanical structures. Their ability to perceive, process, and act hinges entirely on the sophisticated PCBAs that govern their every function. These assemblies are responsible for everything from motor control and sensor data acquisition to complex computations for navigation and decision-making.

Types of Robotics PCBA Applications:

- Motor Control Units (MCUs):High-current, high-precision control for robot joints and movement. These require robust power planes and careful thermal management.

- Sensor Integration Boards:Connecting and processing data from cameras, lidar, ultrasonic, and force sensors, often requiring high-speed data transfer and signal integrity.

- Central Processing Units (CPUs) / AI Inference Engines:The “brain” of the robot, executing complex algorithms, machine learning models, and real-time path planning. AI PCB assembly in this context demands high-density interconnect (HDI) and advanced packaging.

- Communication Modules:Enabling wireless (Wi-Fi, Bluetooth, 5G) and wired ( Ethernet, EtherCAT) communication for connectivity within a robotic system and with external networks.

- Power Management Boards:Ensuring stable and efficient power distribution across all components.

The performance of a robot —its speed, accuracy, reliability, and intelligence—is directly linked to the quality and design of its robotics PCBA. Manufacturers specializing in PCB assembly Robotics understand these demanding requirements.

3. PCBA’s Core Function in Industrial Control Systems

Industrial control systems are the backbone of modern factories, utilities, and infrastructure. They manage everything from discrete manufacturing processes to continuous process control in industries like chemicals, oil & gas, and energy. Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, and Human -Machine Interfaces (HMIs) all rely heavily on advanced PCBAs.

Key Areas for Industrial Control PCBA:

- PLCs and RTUs (Remote Terminal Units):The core logic controllers requiring extreme reliability, long lifecycles, and often, resistance to harsh environments.

- Sensors and Actuators:Interface boards for connecting myriad sensors (temperature, pressure, flow) and actuators (valves, motors), demanding precise analog and digital signal processing.

- Communication Gateways:Enabling secure and robust communication between different parts of a factory network, often using industrial protocols like Modbus, Profibus, or Ethernet/IP.

- Power Supplies and Conditioning:Providing stable, clean power in often noisy electrical environments.

- Edge Computing Devices:Performing data aggregation and preliminary analysis close to the source, supporting the Industrial Internet of Things ( IIoT). This is where industrial control PCBA meets the demands of modern data processing.

Reliability is paramount in PCBA in industrial control. Failures can lead to significant downtime, safety hazards, and financial losses. Therefore, industrial control PCB assembly demands stringent quality control and robust component selection.

4. Unique Challenges and Requirements for Robotics PCBA & Industrial Control PCBA

While general PCBA focuses on functionality, the specialized domains of robotics and industrial control introduce a unique set of challenges:

- Harsh Environments:Exposure to extreme temperatures, humidity, vibrations, dust, chemicals, and electromagnetic interference (EMI) requires robust materials, conformal coatings, and shielding.

- High Reliability & Long Lifespan:Components must operate flawlessly for extended periods, often 24/7, without maintenance. This necessitates rigorous testing, high-quality components, and robust design practices.

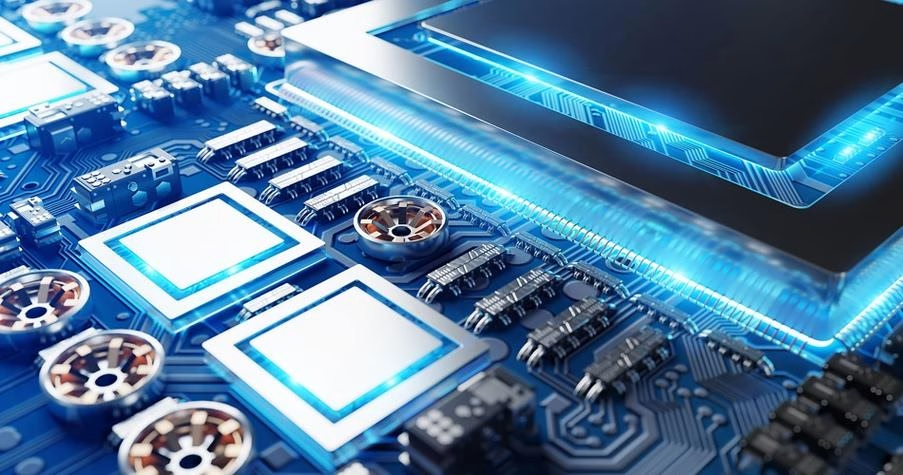

- Miniaturization & High Density:As robots become more compact and industrial control cabinets shrink, PCBAs need to pack more functionality into smaller footprints, driving the use of HDI, microvias, and advanced component packaging (e.g., B GA, QFN).

- Power Management:Robotics, in particular, often involve high current draw for motors and actuators, requiring efficient power delivery and effective thermal management solutions like heavy copper layers and heat sinks.

- High-Speed Data Processing:The increasing integration of AI, machine vision, and complex sensor arrays demands PCBAs capable of handling vast amounts of data at high speeds, preserving signal integrity across multiple layers.

- Cost-Effectiveness:While reliability is key, mass production of robots and industrial modules also requires cost-effective manufacturing without compromising quality.

- Traceability:Full traceability of components and manufacturing processes is often a regulatory or quality requirement, especially in safety-critical applications.

Meeting these challenges requires specialized expertise in design, component sourcing, assembly processes, and testing.

5. How AI and Advanced Technologies Are Transforming PCBA

The very systems that rely on advanced PCBAs are now also leveraging AI to enhance the PCBA process itself. This symbiotic relationship is pushing the boundaries of what’s possible in manufacturing and quality control.

AI ‘s Impact on PCB Assembly:

- Automated Optical Inspection (AOI):AI-powered AOI systems are far more accurate and faster at detecting defects (e.g., solder joint issues, missing components, polarity errors) than traditional methods, learning from vast datasets of good and bad assemblies.

- Predictive Maintenance:AI analyzes data from assembly line equipment to predict potential failures, allowing for proactive maintenance and reducing downtime.

- Process Optimization:Machine learning algorithms can optimize pick-and-place routes, reflow oven profiles, and other manufacturing parameters to improve efficiency and yield.

- Design for Manufacturability (DFM) Feedback :AI tools can analyze PCB designs for potential manufacturing issues before production even begins, saving significant time and cost. This is a crucial aspect for PCB Assembly service in AI, enhancing the overall process.

- Robotic Assembly:Advanced robotics PCB assembly systems themselves are becoming more intelligent, utilizing vision systems and force sensors to handle delicate components and perform precise operations with greater autonomy.

Beyond AI, other advanced technologies like 3D printing for prototypes, advanced materials for improved thermal or electrical performance, and sophisticated testing methodologies (e.g ., X-ray inspection, flying probe testing) are continually refining the PCBA landscape.

6. Key Considerations When Choosing a PCBA Partner

For companies developing robotics or industrial control systems, selecting the right PCB Assembly service in robotics is paramount. Here are critical factors to consider:

| Factor | Description | Benefit |

| Experience & Expertise | Proven track record in robotics or industrial-grade PCBAs. | Ensures understanding of unique challenges and requirements. |

| Technology & Equipment | State-of-the-art assembly lines, AOI, X-ray, and testing capabilities. | Guarantees precision , quality, and ability to handle complex designs (e.g., HDI). |

| Quality Control & Certifications | Adherence to ISO 9001, IPC standards , and industry-specific certifications. | Provides assurance of consistent quality and reliability. |

| Supply Chain Management | Robust processes for sourcing authentic, high-quality components. | Minimizes risk of counterfeit parts and ensures timely delivery. |

| Testing & Validation | Comprehensive functional testing, environmental stress screening, and burn-in testing. | Verifies performance under specified conditions and increases product lifespan. |

| Design for Manufacturability (DFM) Support | Ability to provide feedback on designs to optimize for production. | Reduces design iterations, costs, and time-to-market. |

| Scalability & Flexibility | Capacity to handle both prototyping and high-volume production efficiently. | Supports product lifecycle from development to mass deployment. |

A true partner will not only assemble boards but also provide valuable insights and support throughout the product development cycle, acting as an extension of your engineering team.

7. Robotics PCBA & Industrial Control PCBA FAQs

Robotics and industrial control PCBAs typically require higher reliability, ruggedness for harsh environments (vibration, temperature, EMI), enhanced thermal management, and often higher density or specialized components for high-speed processing and power delivery.

AI significantly enhances automated optical inspection (AOI) for defect detection, optimizes manufacturing parameters, predicts equipment maintenance needs, and helps in design for manufacturability (DFM) analysis , leading to higher quality, efficiency, and reduced costs.

Multi-layer rigid PCBs are standard for complexity and signal integrity. High-Density Interconnect (HDI) PCBs are crucial for miniaturization. Flex and rigid-flex PCBs are increasingly used in robotics for space constraints and dynamic applications.

Robotics PCBAs often deal with high power consumption from motors and processors, generating significant heat. Effective thermal management prevents overheating, which can degrade performance, reduce component lifespan, and lead to system failure.

8. Summary

Robotics PCBA and industrial control PCBA are the foundational electronic components that enable the sophisticated functionality of modern advanced technology. From handling complex sensor data and precise motor control in robots to ensuring the unwavering reliability of industrial automation infrastructure, the demands placed on these assemblies are incredibly high. These sectors require PCBAs that can withstand harsh environments, provide exceptional performance, ensure long lifespans, and pack immense processing power into increasingly compact forms. The integration of Artificial Intelligence is not only being embedded within these advanced systems but is also revolutionizing the PCBA manufacturing process itself, driving unprecedented levels of quality, efficiency, and intelligence.

Key Takeaways

- PCBA is indispensable for the functionality and performance of robotics and industrial control systems, acting as their electronic brain and nervous system.

- Key challenges include harsh environment resilience, high reliability, miniaturization, efficient power management, and high-speed data processing.

- AI is transforming PCBA by enhancing automated inspection, optimizing manufacturing processes, enabling predictive maintenance, and improving DFM.

- Choosing a PCBA partner with specialized expertise, advanced technology, stringent quality control, and robust testing capabilities is crucial for success in these demanding fields.

- The future of robotics and industrial control will continue to push the boundaries of PCBA technology, driving innovation in materials, design, and manufacturing processes.

Table of Contents

Get Your PCB Quote!