Aluminum PCB Guide: Enhanced Thermal Management

Aluminum PCB represents an advancement in printed circuit board technology, specifically addressing the challenge of thermal management in modern electronics.

Get Your PCB Quote!

Table of Contents

In the rapidly evolving world of electronics, components are becoming smaller, more powerful, and consequently, generate more heat. Managing this thermal output is crucial for ensuring the longevity and reliability of electronic devices. This is where the aluminum PCB, or aluminum printed circuit board, emerges as a pivotal technology. Unlike traditional FR-4 boards, aluminum core PCBs leverage the superior thermal conductivity of aluminum to efficiently dissipate heat, making them indispensable for high-power applications.

This comprehensive guide delves into the fundamental aspects of aluminum circuit boards, exploring their unique structure, benefits, various types, and widespread applications, providing insights for anyone looking to understand or implement this robust technology.

1. What are Aluminum PCBs?

An aluminum PCB, also known as a Metal Core PCB (MCPCB) or an aluminum backed PCB, is a type of printed circuit board that incorporates a base metal material, typically aluminum, as part of its substrate . The core function of this aluminum layer is to act as a highly efficient heat sink, drawing heat away from critical components. This characteristic makes them fundamentally different from conventional FR-4 boards, which are primarily designed for electrical insulation rather than thermal dissipation.

The demand for these boards has surged with the proliferation of high-brightness LEDs, power conversion systems, and automotive electronics, all of which require robust thermal management solutions to maintain performance and extend operational life.

2. The Unique Aluminum PCB Stackup

The distinctive thermal capabilities of an aluminum PCB board stem from its unique layered construction. A typical Aluminum PCB stackup comprises four main layers:

1) Circuit Layer (Copper): This is the uppermost layer, typically 1 to 10 ounces of copper foil, etched to form the desired circuit patterns, tracks, and pads. Its thickness determines the current-carrying capacity.

2) Dielectric Layer (Thermal Insulating Layer): This is the most crucial layer for thermal performance. It’s a thin layer (often 50-200 µm thick) of thermally conductive, electrically insulating material, such as ceramic-filled epoxy. It ensures electrical isolation between the copper circuit and the aluminum core while efficiently transferring heat. Its thermal conductivity is far superior to standard FR-4 prepreg.

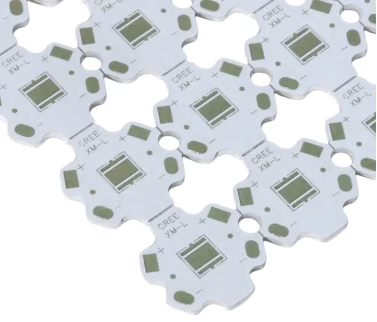

3) Aluminum Base Layer (Metal Core): This is the foundation of the aluminum core PCB. It’s typically an aluminum alloy (e.g., 1100, 3003, 5052 series), chosen for its excellent thermal conductivity, mechanical strength, and relatively low cost. It provides structural integrity, dissipates heat, and can offer electromagnetic shielding.

4) Aluminum Base Membrane (Optional): In some designs, particularly for single-sided boards, an aluminum base membrane may be applied to the bottom side of the aluminum core to protect it from oxidation and provide additional electrical insulation.

3. What are the Key Advantages of Aluminum Circuit Boards?

The architectural advantages of aluminum printed circuit boards translate into several significant benefits:

- Superior Thermal Dissipation:This is the primary benefit. Aluminum can dissipate heat 8 to 9 times faster than FR-4, preventing component overheating and extending product lifespan. This is especially vital for high-power devices like LEDs and power converters.

- Enhanced Durability and Mechanical Strength:The aluminum base provides exceptional rigidity and durability, making the PCBs highly resistant to thermal expansion, vibrations, and mechanical stress, which is crucial for automotive and industrial applications.

- Improved Electrical Performance:Better thermal management leads to more stable electrical parameters, reducing signal distortion and improving overall reliability. The aluminum base also offers effective electromagnetic interference (EMI) shielding.

- Reduced Size and Weight:By efficiently managing heat, designers can often reduce or eliminate bulky external heat sinks, leading to more compact and lighter designs.

- Cost-Effectiveness:While initially slightly more expensive than FR-4 for single-layer designs, the long-term benefits in reliability, reduced need for additional cooling components, and extended product life often make them more cost-effective.

- Environmental Friendliness:Aluminum is non-toxic and easily recyclable, aligning with modern environmental standards.

4. What are the Types of Aluminum PCBs?

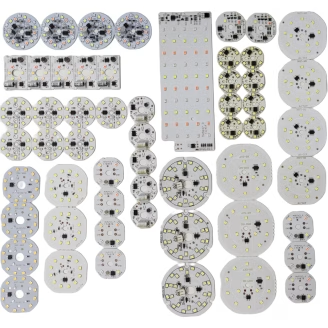

Beyond the standard single-layer design, several specialized Types of Aluminum PCBs cater to diverse application needs:

Standard Aluminum PCBs

These are the most common type, featuring a single copper circuit layer bonded to the dielectric and aluminum base. Ideal for simple, high-power applications.

Flexible Aluminum PCBs

An emerging type, these combine the thermal benefits of aluminum with the flexibility required for certain form factors. They typically use a thin aluminum foil or a specialized dielectric that allows for some degree of bending, suitable for dynamic or irregular shapes where conventional rigid PCBs cannot fit.

Hybrid Aluminum PCBs

These boards integrate an aluminum core with traditional FR-4 layers. For instance, a rigid FR-4 PCB might be bonded to an aluminum base for improved thermal management in specific areas or for cost optimization in designs where not all layers require direct thermal connection to aluminum.

Multi-Layer Aluminum PCBs

While challenging to manufacture due to the difficulty of creating reliable electrical connections through the thick aluminum core, multi-layer aluminum PCBs exist for extremely high-density, high-power applications. These typically involve stacking multiple circuit layers on a thermally conductive dielectric, often with thermal vias connecting to the aluminum base. They are more complex and costly to produce.

Through-Hole Aluminum PCBs

These designs allow components to be mounted with through-hole technology, where the component leads pass through the PCB and are soldered on the opposite side. When combined with an aluminum core, these can provide excellent mechanical stability and direct thermal pathways for heat-generating components.

5. Diverse Applications of Aluminum PCBs

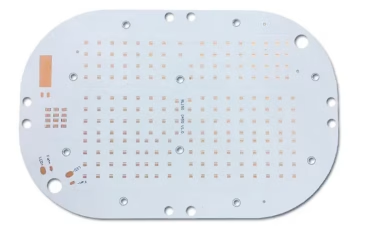

The unique properties of aluminum PCB boards make them ideal for a wide array of applications, particularly where heat dissipation is critical:

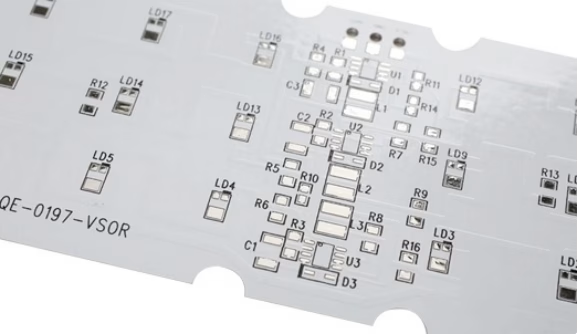

- LED Lighting:The most prominent application. Aluminium LED PCB are essential for high-brightness and high-power LED arrays in street lights, automotive lighting (headlights), general illumination, and display backlighting, preventing thermal runaway and ensuring consistent light output.

- Automotive Industry:Used in power regulators, motor controllers, ignition systems, LED headlights, and hybrid/electric vehicle power management due to their thermal performance and vibration resistance.

- Power Electronics:Critical for power supplies, voltage regulators, DC/DC converters, solid-state relays, and uninterruptible power supplies (UPS) where efficient heat transfer is paramount.

- Consumer Electronics:High-power audio amplifiers, computing devices requiring robust cooling, and other heat-intensive consumer products.

- Medical Devices:High-intensity surgical lighting, diagnostic equipment, and other medical electronics demanding reliability and consistent performance under heat.

- Industrial Equipment:Motor drives, industrial power tools, and automation equipment that operate in high-temperature environments.

6. Design and Manufacturing Considerations for Aluminum PCB

Designing and manufacturing aluminum PCB boards requires specific considerations to leverage their benefits effectively:

- Material Selection:Choosing the right aluminum alloy (e.g., 1100 for high thermal conductivity, 5052 for higher strength) and dielectric material (balancing thermal conductivity with dielectric strength) is critical.

- Thermal Management Design:Incorporating thermal vias to enhance heat transfer, careful component placement to minimize hot spots, and simulations to predict thermal performance are standard practices.

- Etching and Drilling:Aluminum’s properties necessitate specialized etching processes and tooling for drilling compared to FR-4.

- Solder Mask and Surface Finish:Appropriate solder masks and surface finishes are vital for ensuring good solder ability and protecting the copper traces from oxidation and environmental factors.

- Manufacturing Partner:Selecting an experienced aluminum PCB manufacturer is crucial for ensuring quality and reliability, especially for complex designs or high volumes.

7. Comparison between Aluminum PCB and FR-4 PCB

To highlight the distinct advantages of aluminum PCBs, it’s useful to compare them directly with traditional FR-4 boards:

| Feature | Aluminum PCB | FR-4 PCB |

| Primary Advantage | Superior Thermal Management | Cost-Effective Electrical Insulation |

| Thermal Conductivity | Excellent (Typically 1-10 W/m·K for dielectric, base is ~200 W/m·K ) | Poor (Typically 0.2-0.4 W/m·K) |

| Heat Dissipation | Highly efficient, acts as a heat sink | Poor, requires external heat sinks for high power |

| Mechanical Strength | High durability, rigid, resistant to vibration | Good, but less robust than metal core |

| Cost (Single-sided) | Generally higher | Lower |

| EMI Shielding | Good due to metal core | Minimal inherent shielding |

| Applications | LED lighting, automotive, power electronics | General electronics, low-power devices |

| Environmental | Recyclable, non-toxic | Less recyclable, can contain halogenated compounds |

8. Aluminum PCB FAQs

Aluminum PCBs offer vastly superior thermal dissipation, preventing overheating, extending component life, and improving overall system reliability, which FR-4 cannot match in high-power scenarios.

Yes, aluminum is a highly recyclable and non-toxic material, making aluminum PCBs a more eco-friendly choice compared to some other PCB substrates.

The primary layers are the copper circuit layer, the thermally conductive dielectric layer, and the aluminum base layer (or aluminum core).

Yes, but they are more complex and costly to manufacture than single-layer or hybrid aluminum PCBs. Multi-layer designs require specialized techniques for creating electrical connections through the metal core while maintaining thermal performance.

The dielectric layer is critical; it provides electrical insulation between the copper circuit and the conductive aluminum core while simultaneously facilitating efficient heat transfer from the components to the aluminum heat sink.

9. Summary

Aluminum PCBs represent a critical advancement in printed circuit board technology, specifically addressing the growing challenge of thermal management in modern electronics. With their unique Aluminum PCB stackup , they offer unparalleled thermal dissipation, enhanced durability, and improved electrical performance compared to conventional FR-4 boards. From aluminium LED PCB applications to automotive systems and power electronics, the versatility and robustness of aluminum core PCBs make them an indispensable component for high-performance and high-reliability devices. Understanding their various types, advantages, and design considerations is key to harnessing their full potential in contemporary electronic designs.

Key Takeaways

- Aluminum PCBs excel at thermal management, dissipating heat much more efficiently than FR-4 boards.

- Their unique stackup includes a copper circuit layer, a thermally conductive dielectric, and an aluminum base.

- Key benefits include superior thermal dissipation, enhanced durability, EMI shielding, and potential for smaller designs.

- Common types include standard, flexible, hybrid, and multi-layer aluminum PCBs, each suited for specific applications.

- They are widely used in LED lighting, automotive electronics, power supplies, and other high-heat generating devices.

- Careful material selection and design are crucial for optimizing aluminum PCB performance.

Table of Contents

Get Your PCB Quote!