Polyimide vs. LCP: Best Substrate for Your Flex PCB?

Compare Polyimide and LCP for flex PCB substrate. Discover which one excels in high-frequency, thermal stability, and cost for your flexible circuit design.

Get Your PCB Quote!

Table of Contents

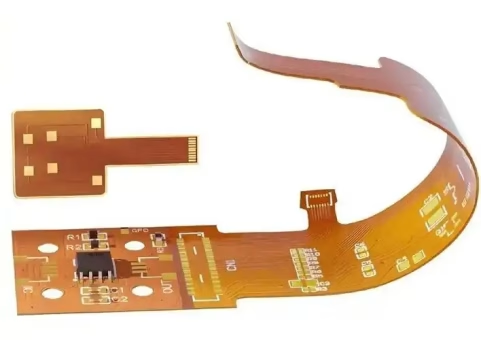

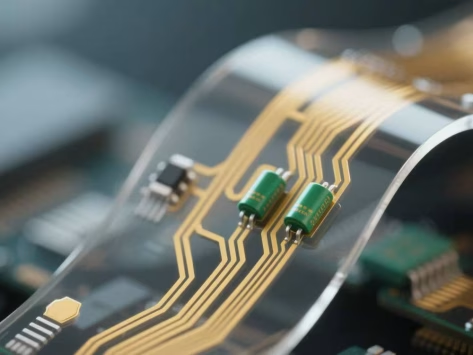

In the rapidly evolving landscape of modern electronics, flexible printed circuit boards(flex PCBs) have become indispensable. Their ability to bend, twist, and conform to intricate designs allows for smaller, lighter, and more versatile devices, from smartphones and wearables to advanced medical implants and aerospace components. However, the performance and reliability of these flexible circuits hinge critically on one fundamental decision: the choice of substrate material.

Two prominent materials dominate this crucial selection process: Polyimide(PI) and Liquid Crystal Polymer(LCP). Both offer distinct advantages and a unique set of properties, making them suitable for different applications. While Polyimide has long been the workhorse of the flex PCB industry, LCP is gaining attention, particularly for high-frequency applications. This comprehensive guide will delve into the characteristics, advantages, and limitations of Polyimide and LCP, helping engineers and designers make an informed choice for their next project.

1. The Rise of Flexible PCBs

Flexible PCBs represent a significant advancement over traditional rigid circuit boards. They utilize thin, flexible dielectric materials as a base, allowing circuits to be integrated into three-dimensional spaces, reducing overall size and weight, and improving reliability by eliminating connectors. This adaptability is critical in today’s compact and high-performance electronic devices.

The core of any flex PCB is its substrate material, which provides mechanical support, electrical insulation, and determines the board’s flexibility, thermal characteristics, and high-frequency performance. The right substrate ensures optimal functionality and longevity under various operating conditions. Choosing between materials like Polyimide and LCP becomes paramount, especially when balancing factors such as durability, signal integrity, and cost-effectiveness.

2. Polyimide(PI)

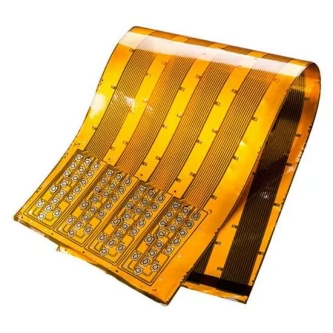

(Polyimide)

Polyimide, often recognized by brand names like Kapton, is a well-established and widely used material in flexible circuit manufacturing. Its popularity stems from an excellent balance of properties that make it highly versatile and reliable for a broad range of applications. PI films typically range in thickness from 12.5 to 125 micrometers(µm), offering various levels of flexibility and mechanical support.

2.1 Key Characteristics and Advantages of Polyimide:

- Exceptional Thermal Stability:Polyimide boasts a high glass transition temperature (Tg) and remains stable across a wide temperature range, making it suitable for applications that endure extreme heat or require high-temperature processing. This thermal stability ensures consistent performance in demanding environments.

- Superior Mechanical Strength:PI offers excellent tensile strength and tear resistance, contributing to its durability and ability to withstand repeated bending cycles without degradation. This mechanical strength is crucial for flex PCBs that undergo dynamic flexing.

- Excellent Electrical Insulation:Polyimide provides robust dielectric properties, ensuring effective insulation between circuit layers and minimizing signal loss.

- Chemical Resistance:It exhibits good resistance to many chemicals, oils, and solvents, enhancing its lifespan in challenging industrial or environmental conditions.

- Cost-Effectiveness:Compared to some other high-performance materials, Polyimide is generally more cost-effective, making it a preferred choice for applications requiring moderate durability and performance without breaking the budget.

- Mature Manufacturing Processes:The industry has extensive experience and established processes for fabricating Polyimide-based flex PCBs, which often translates to higher yields and faster production times.

2.2 Typical Applications of Polyimide Flex PCBs:

- Consumer electronics (smartphones, cameras, laptops)

- Automotive electronics

- Medical devices

- Industrial controls

- Aerospace and defense (where high reliability and endurance are paramount)

While Polyimide excels in many areas, its moisture absorption can be a drawback for extremely sensitive high-frequency applications, where water molecules can increase the dielectric constant and loss tangent, potentially degrading signal integrity.

3. Liquid Crystal Polymer(LCP)

Liquid Crystal Polymer (LCP) has emerged as a high-performance material, carving out a niche in specific applications, particularly those demanding superior high-frequency performance and environmental stability. LCP is characterized by its unique molecular structure, which combines properties typically found in both plastics and liquid crystals.

3.1 Key Characteristics and Advantages of LCP:

- Exceptional Low Dielectric Constant (Dk) and Loss Tangent (Df):This is LCP’s standout feature. Its stable and low Dk and Df across a broad frequency range (up to 100 GHz) make it an ideal material for high-frequency and millimeter-wave applications where signal integrity is critical. This minimizes signal attenuation and distortion, crucial for 5G, radar, and satellite communication systems.

- Superior Moisture Resistance:LCP exhibits extremely low moisture absorption, significantly outperforming Polyimide. This property is vital in harsh, humid environments, as moisture can negatively impact the electrical properties of the substrate. Low moisture absorption also contributes to excellent dimensional stability.

- Excellent Dimensional Stability:LCP maintains its shape and size very well under varying temperature and humidity conditions, which is crucial for precise circuit fabrication and long-term reliability. Its coefficient of thermal expansion (CTE) is closely matched to copper, further enhancing dimensional stability and reducing stress on solder joints during thermal cycling.

- Chemical Resistance:LCP offers superior chemical resistance, making it suitable for applications exposed to aggressive chemicals or solvents.

- Radiation Resistance:It demonstrates good resistance to radiation, broadening its utility in specialized environments.

- Mechanical Strength:LCP also possesses good mechanical strength, contributing to the durability of the flex circuit.

3.2 Typical Applications of LCP Flex PCBs:

- High-speed data communication (e.g., 5G antennas, servers)

- RF/Microwave modules

- Automotive radar sensors

- Medical imaging and diagnostic equipment

- Wearable electronics requiring low profile and high performance

- Satellite communication systems

While LCP offers compelling advantages for high-frequency applications, it can be more expensive than Polyimide and may have limitations in terms of processability for certain complex designs due to its rigid chain structure.

4. Polyimide vs. LCP

To summarize the key differences and help in decision-making, let’s look at a direct comparison of Polyimide and LCP across several critical parameters:

| Feature | Polyimide (PI) | Liquid Crystal Polymer (LCP) | Implication for Design |

| Dielectric Constant (Dk) | ~3.2 – 3.5 | ~2.9 – 3.1 | Lower Dk in LCP translates to faster signal propagation and better signal integrity, especially at higher frequencies. |

| Loss Tangent (Df) | ~0.002 – 0.009 | ~0.00 2 – 0.003 | LCP has a consistently lower Df across a wide frequency range, minimizing signal loss for high-frequency applications. |

| Moisture Absorption | Moderate (0.8 – 3.0%) | Extremely Low (<0.04%) | LCP maintains electrical stability better in humid environments; PI’s Dk/Df can vary with moisture. |

| Thermal Stability | Excellent (Tg >250°C) | Excellent (Melting Point ~280-315°C) | Both handle high temperatures well, but PI’s general thermal resistance is a key advantage. |

| Coefficient of Thermal Expansion (CTE) | Higher (12-20 ppm/°C) | Lower, matches copper (10-17 ppm/°C) | LCP’s CTE match to copper reduces stress and improves reliability, especially in thermal cycling. |

| Flexibility | Excellent, high flex endurance | Good, but can be more brittle at very low temperatures; excellent dynamic flexing. | Both are flexible, PI is traditionally known for high flex endurance. |

| Cost-Effectiveness | Generally more cost-effective | Higher cost | PI is preferred for budget-conscious projects; LCP for performance-critical applications. |

| High-Frequency Performance | Good, but Dk/Df can increase with frequency/moisture | Superior, stable Dk/Df up to 100 GHz | LCP is the material of choice for demanding RF/microwave applications. |

5. Choosing the Right Flexible PCB Substrate

The decision between Polyimide and LCP ultimately boils down to the specific requirements of your application:

- For General-Purpose & Cost-Sensitive Applications:If your design requires good flexibility, high thermal stability, moderate electrical performance, and cost-effectiveness, Polyimide is likely the best choice. It’s suitable for a vast array of consumer, industrial, and medical devices that do not operate at extremely high frequencies or in severely humid conditions.

- For High-Frequency & Harsh Environment Applications:If your design demands superior signal integrity at high frequencies (e.g., 5G, radar, RF modules), extreme moisture resistance, excellent dimensional stability, and a close CTE match to copper, LCP is the preferred material. Its premium performance justifies the higher cost in mission-critical applications where performance cannot be compromised.

Engineers must carefully weigh the trade-offs between performance, reliability, manufacturing complexity, and budget. While Polyimide continues to be a dominant and versatile option, LCP offers a compelling solution for the most challenging flexible circuit designs, particularly as devices push the boundaries of high-speed data transmission and miniaturization.

6. Polyimide and LCP FAQs

The primary advantage of LCP is its superior high-frequency performance, characterized by a very stable and low dielectric constant and loss tangent across a wide frequency range. Additionally, its extremely low moisture absorption is critical for maintaining electrical stability in humid environments.

Generally, yes. Polyimide is typically more cost-effective due to its widespread use, mature manufacturing processes, and lower raw material cost compared to LCP. However, for specialized, high-performance applications where LCP’s properties are essential, the overall cost-benefit might favor LCP due to enhanced reliability and performance.

Yes, LCP offers good flexibility and dynamic flexing capabilities, making it suitable for applications requiring bending. While Polyimide is often highlighted for its high flex endurance, LCP is also very capable in flexible applications, particularly those where maintaining signal integrity during motion is crucial.

While typically used as primary substrates, they are generally not mixed within the same flexible layer due to differing processing requirements and material properties. However, hybrid structures with different materials on different layers or parts of a board can exist, though this is complex.

Both can support HDI, but LCP’s superior dimensional stability and low CTE make it particularly advantageous for ultra-fine pitch and high-density applications where precise alignment is crucial, especially in high-frequency contexts.

Neither is generally considered a strong thermal conductor. Heat dissipation largely depends on the PCB design, copper thickness, and thermal vias. However, LCP’s excellent thermal stability means it maintains its electrical and mechanical properties better at elevated temperatures.

Both materials are generally stable and safe once manufactured. However, LCP can be more difficult to recycle due to its complex polymer structure compared to some other plastics. Manufacturers are continually working on more sustainable processing methods for both.

7. Summary

The choice between Polyimide and Liquid Crystal Polymer(LCP) for flexible PCB substrates is a critical design decision influenced by application requirements. Polyimide, the industry stalwart, offers an excellent balance of thermal stability, mechanical strength, and cost-effectiveness, making it suitable for a wide range of general-purpose and moderately demanding applications. LCP, on the other hand, excels in high-frequency environments, boasting superior low dielectric constant, low loss tangent, and exceptional moisture resistance, ideal for cutting-edge communication and radar systems. Understanding the distinct advantages of each material allows engineers to select the optimal substrate, ensuring both performance and reliability in the compact, flexible electronics of tomorrow.

Key Takeaways

- Polyimide (PI) offers thermal stability, mechanical strength, and is cost-effective for general flexible PCB applications.

- Liquid Crystal Polymer (LCP) is superior for high-frequency performance due to low, stable Dk/Df and excellent moisture resistance.

- LCP’s close Coefficient of Thermal Expansion (CTE) to copper enhances reliability in thermal cycling.

- Consider Polyimide for budget-conscious, moderate-performance flex PCBs.

- Opt for LCP when designing high-speed, RF, or moisture-sensitive flexible circuits.

Table of Contents

Get Your PCB Quote!