A Complete Guide to medical PCB assembly

Learn everything about medical PCB assembly, its processes, components, and applications in healthcare devices.

Get Your PCB Quote!

Table of Contents

- 1. Comprendre les PCB médicaux

- 2. Principales caractéristiques du PCBA médical

- 3. Applications dans les dispositifs médicaux

- 4. Le processus d'assemblage des dispositifs médicaux

- 5. Défis de l'industrie

- 6. PCBA dans les appareils de luminothérapie rouge

- 7. PCBA dans les dispositifs d'alerte médicale

- 8. Choisir le bon partenaire

- 9. Innovation et avenir

- 10. Assemblage de circuits imprimés médicaux Questions fréquentes

- 11. Résumé

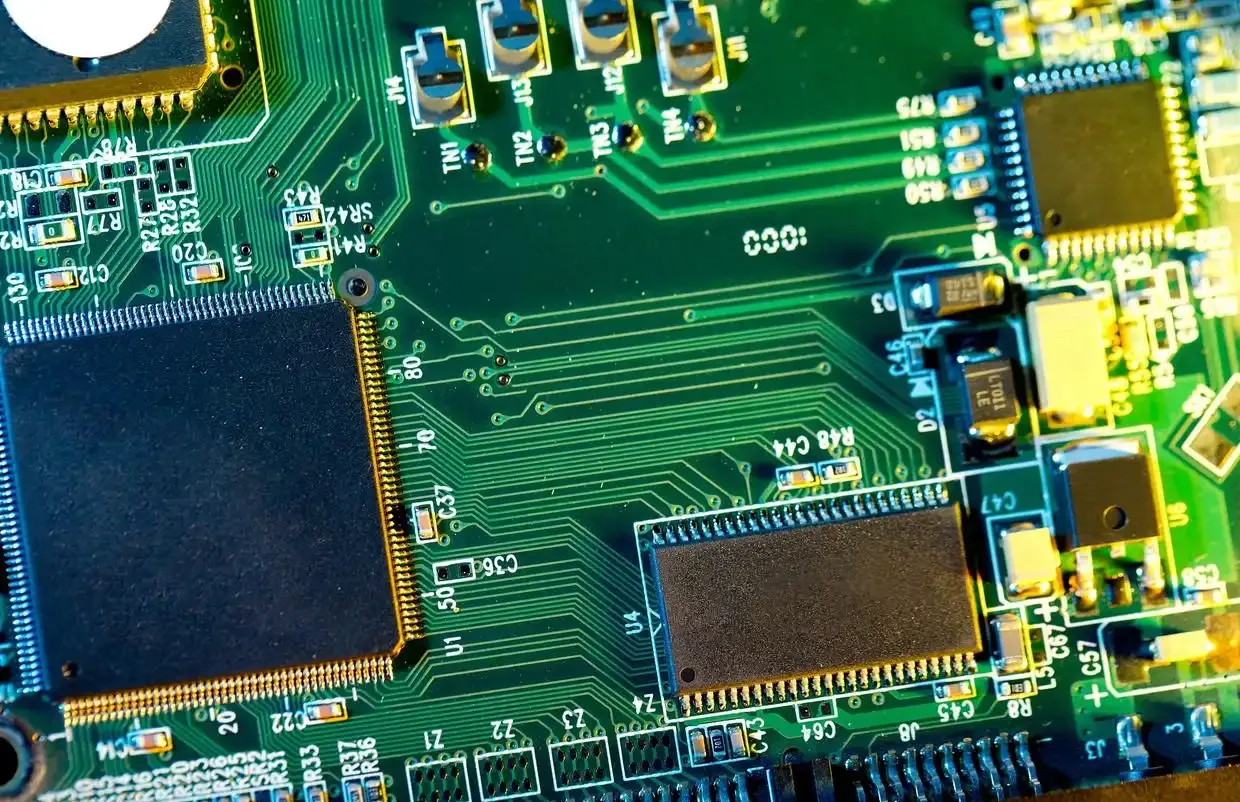

Today, modern healthcare needs the utmost precision, speed, and safety. All are made possible through solid electronic systems. In the middle of these innovations lies medical PCB assembly. From diagnostic instruments to wearable sensors, printed circuit boards provide the function across the board in medical treatment.

1. Understanding Medical PCBs

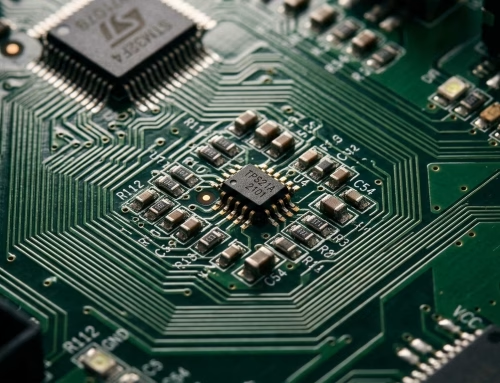

Printed circuit boards in medicine demand higher standards than can be expected from regular electronics. Failure of any medical PCBA may prove life-threatening. The components and layout are designed for very sensitive use with extra-high levels of quality control at the production stage.

These boards run everything from surgical instruments to personal monitoring systems. The trusted medical PCB manufacturer works under strict regulations, ensuring every circuit functions without any fault.

2. Key Features of Medical PCBA

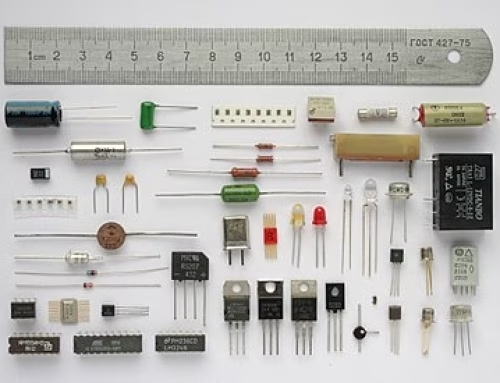

These circuit boards are distinguished by their reliability in critical situations. Smaller size, thermal resistance, and electromagnetic compatibility are among the required features of a PCBA medical machine. High-end ceramics or composites usually come into play to ensure zero interference of any kind.

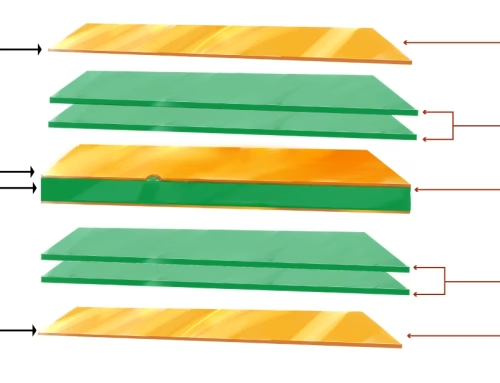

Due to arrays of dense interconnections and multilayer designs, the boards remain compact, with high performance retained. Therefore, the healthcare technology being very dynamic, a key requirement is flexibility for upgrades and integration.

3. Applications Across Medical Devices

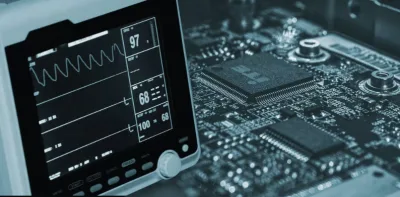

The application field is quite broad. As one example in PCBA in medical device technology, it powers heart monitors, MRIs, and infusion pumps. Ultrasensitive sensors collect and process real-time data for diagnostic imaging.

Recent changes have spearheaded the rise of portable and home-use instruments. With this, smaller but efficient PCBs are needed. Medical electronics assembly nowadays leans towards miniaturized, battery-efficient units equipped with wireless connectivity.

4. The Process of Medical Device Assembly

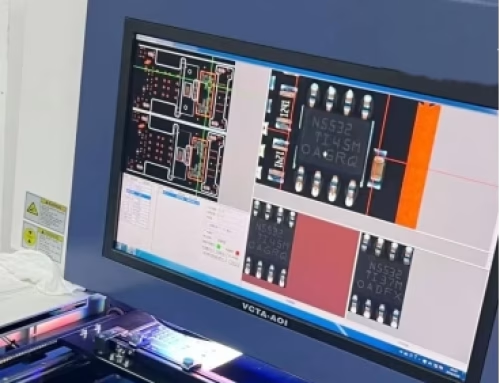

The assembly of medical electronics covers a vast terrain of several stages. It begins with design and layout. Engineers must see that the function of the board aligns with the regulatory compliance. With prototyping approved, the sourcing of components for mounting commences using automated machines.

Soldering, coating, and the like all need to be completed within cleanroom environments. A series of thermal testing, inspection, and software integration follows. Smooth medical device assembly guarantees both functionality and safety.

5. Challenges in the Industry

Several obstacles confront this industry. An entirely new chapter to be handled in the changing regulations. Such standards, too, can differ across countries. The second would be that designs frequently require micro-components. The presence of these materials increases errors.

Testing protocols for medical PCB assembly services are indeed more stringent than those for consumer electronics. There are no shortcuts. No shortcuts. One must test dirt for durability, biocompatibility, and sterilization purposes.

6. PCBA in Red Light Therapy Devices

An emerging application is that of PCBA in red light therapy devices. Usage involves skin care, pain alleviation, and wound repair. Embedded PCBs regulate light wavelengths and treatment cycles. Any deviation in timing or light intensity may frustrate the entire treatment.

Here, reliable boards are not simply part of the technical specification; they are a matter of patient safety. Manufacturers should thus ensure thermal stability and uninterrupted power delivery.

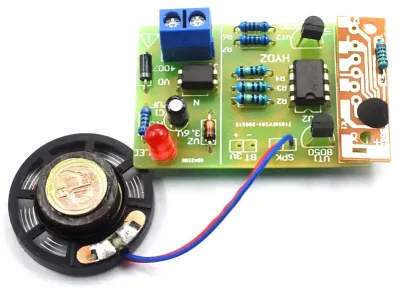

7. PCBA in Medical Alert Devices

Another important application is PCBA in medical alert devices. These devices act as life insurance for the elderly and vulnerable. Their PCBAs provide GPS tracking and emergency alerting, and in some instances, fall detection.

The devices must work in real-time, under varied environmental conditions. Sturdy circuit construction and dependable battery performance are essential. Integration with wireless networks is also a must.

8. Choosing the Right Partner

Trust and experience in a medical PCBA service provider selection matter. Look for those services offering end-to-end solutions, from design to post-production testing. Always ask for certifications and projects done in the healthcare field.

A quality medical PCB assembly service is not just about delivering hardware. It works to lessen time to market and contribute to the longer lifespan of the medical PCBA product. It is not a question of the establishment in price; it’s a genuine consideration of peace of mind.

9. Innovation and the Future

The inner workings must grow smarter by virtue of the intelligence of the devices. Here, next for board demand will be AI-powered diagnostics, robotic surgery, and remote patient care. Hence, the medical PCB assembly manufacturer who acts proactively should keep pace with such technologies.

Flexible PCBs, embedded sensors, and data-encryption layers become a standard. Interlaced with their assembly techniques are also evolving, ranging from 3D component placement to advanced conformal coatings.

10. Medical PCB Assembly FAQs

It is a specialized process of fabricating circuit boards for medical devices, which, unlike the usual industrial PCBA, observes strict health and safety standards.

They are found in MRI machines, wearable monitors, surgical instruments, and home diagnostics tools.

Higher quality control, special materials, and adherence to health regulations are the differences.

To protect from contamination and keep sensitive devices sterile and safe.

Yes. It has been on the test bench long and hard to ensure its reliability, safety, and performance for the long term.

To ensure that light output is well-modulated so that treatments can safely, accurately, and effectively take place.

Manufacturers provide customised solutions based on device requirements and certifications.

Considerations include former experience, relevant certifications, and support for the entire process.

11. Summary

In healthcare, small parts play a big role. Precision in medical PCB assembly directly affects patient safety, device performance, and innovation speed. The choice of the process and the collaborators is a matter of high reliability.

Further research will bring more compact and intelligent solutions. But trusted PCBAs will be the very foundation deep down.

Table of Contents

- 1. Comprendre les PCB médicaux

- 2. Principales caractéristiques du PCBA médical

- 3. Applications dans les dispositifs médicaux

- 4. Le processus d'assemblage des dispositifs médicaux

- 5. Défis de l'industrie

- 6. PCBA dans les appareils de luminothérapie rouge

- 7. PCBA dans les dispositifs d'alerte médicale

- 8. Choisir le bon partenaire

- 9. Innovation et avenir

- 10. Assemblage de circuits imprimés médicaux Questions fréquentes

- 11. Résumé

Get Your PCB Quote!