Choosing a Printed Circuit Manufacturer for Seamless PCB Assembly Manufacturing

Key factors for choosing a PCB manufacturer: technical expertise, quality control, supply chain, scalability, communication, and cost-value balance.

Get Your PCB Quote!

Manufacturing an electronic device requires a smart vision, but the mission completely based on certain components, such as the printed circuit board (PCB). It is an essential part that acts as the foundational platform for your modern electronic gadgets. It connects significant components that ensure proper device performance. You need to connect with a reputable printed circuit manufacturer to achieve reliable and durable PCBs that match your quality requirements. The development of effective printed circuit boards represents only one component of the broader challenge.

Your project’s success depends on selecting the right manufacturer so we need to explore crucial factors for choosing a manufacturer together with practical tips for the selection process.

The Significance of PCB Assembly Manufacturing

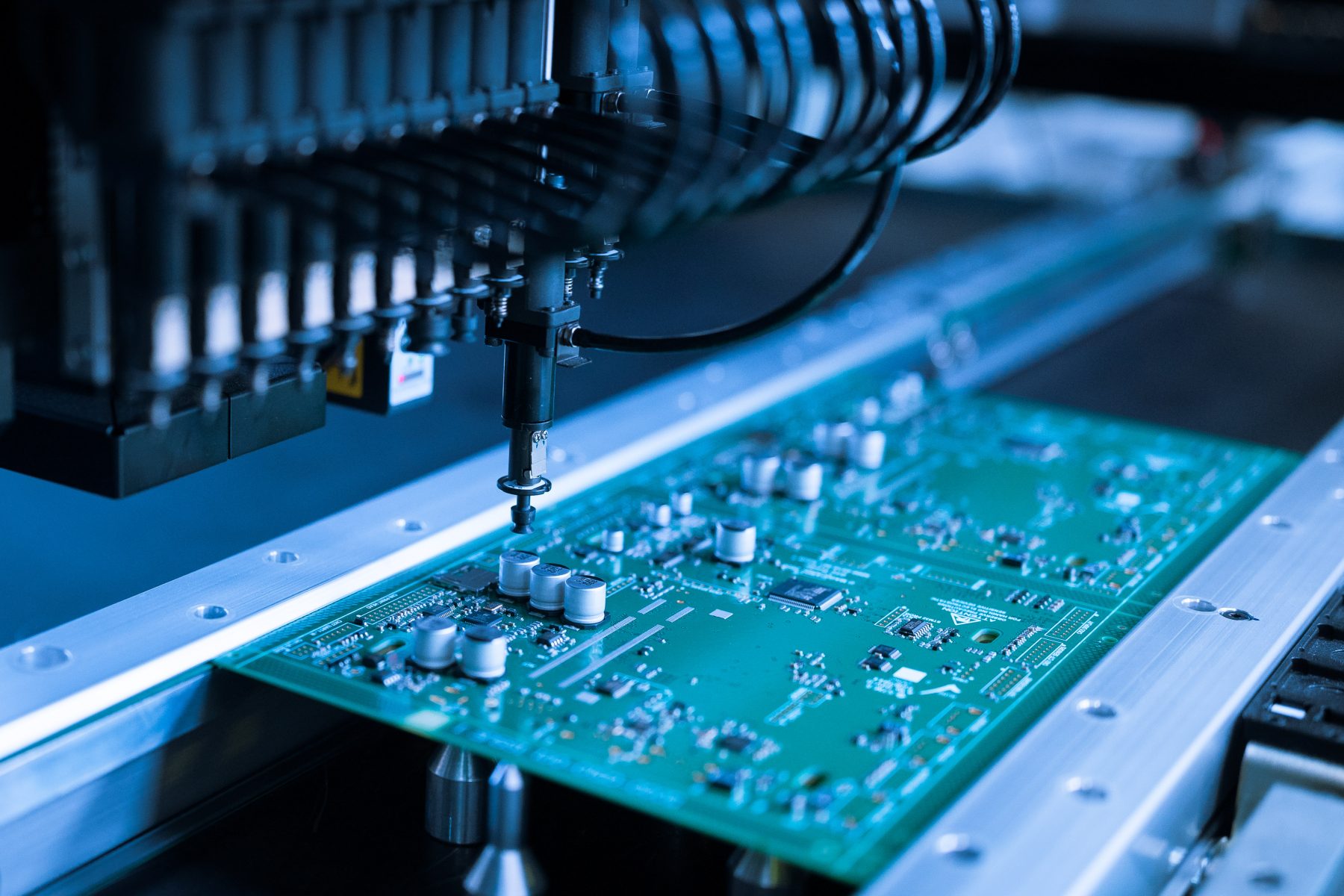

Understanding the importance of PCB assembly manufacturing is essential before you start searching for the right manufacturer. Electronic components are situated on a printed circuit board during assembly which leads to soldering that creates a working board. Advanced equipment and specialized expertise together with precise assembly techniques ensure that the board functions dependably during real-world use.

Choosing a suitable PCB manufacturing assembly designer goes beyond finding a company capable of placing components on a board.

Let’s reveal.

1.Assess Their Technical Expertise and Capabilities

The primary step in selecting a manufacturer requires assessing their technical capabilities. Different manufacturers have specific capabilities which limit them from producing every kind of PCB project. Certain manufacturers focus exclusively on basic single-layer boards whereas others demonstrate expertise in advanced multi-layer PCBs with precise tolerances.

Ask yourself: Your project needs surface-mount technology (SMT) assembly, through-hole assembly or both methods combined? Do your design specifications call for dense interconnect points or particular material requirements?

The latest PCB assembly utilizes automated SMT lines together with pick-and-place machines and reflow ovens to ensure precise production. Reputable manufacturers maintain modern equipment and employ teams skilled in working with complex design patterns. When your design requires fine-pitch components or ball grid arrays (BGAs) ensure that your manufacturer possesses the necessary expertise with these technologies. Ask for some samples of their pervious projects for your security

2.Prioritize Quality Control and Certifications

One manufacturing flaw can cause product breakdowns and customer complaints as well as potential safety risks. Manufacturers producing reliable printed circuits establish comprehensive quality control systems. Seek ISO 9001 certification which demonstrates quality management dedication or IPC standards for electronic assembly such as IPC-A-610. These certifications demonstrate manufacturer compliance with industry best practice standards.

Beyond certifications, ask about their testing procedures. A quality manufacturer will conduct board tests at various production phases to identify problems early on. The AOI method can identify soldering defects but X-ray inspection remains essential for examining concealed BGA connections.

3.Evaluate Their Supply Chain and Component Sourcing

The success of PCB manufacturing assembly depends significantly on having access to necessary components. Manufacturers who maintain a robust supply chain network procure top-grade components quickly which helps to minimize both production timelines and expenses. Manufacturers who fail to anticipate supply chain disruptions—similar to those experienced recently—face production delays.

During your manufacturer evaluation process you should inquire about their component sourcing procedures. Manufacturers either work with reliable suppliers directly or depend on third-party brokers for their component sourcing. Manufacturers should build partnerships with reputable distributors to confirm component authenticity and specification compliance.

4.Consider Scalability and Production Capacity

The level of production your project requires should guide your selection of a manufacturing partner. Are your production plans focused on creating a limited number of prototype PCBs or preparing for extensive high-volume manufacturing? Certain manufacturers focus on low-volume production which involves diverse project types while other manufacturers specifically target large-scale mass production. Verify that the manufacturer’s production capabilities meet your project requirements.

Creating prototypes is a beginning step for startups and mid-sized businesses. Identify manufacturers who provide rapid prototyping services at affordable prices. The ability to test your design and make refinements exists before entering large-scale production.

When you prepare for high-volume production operations you must validate that the manufacturer can expand output while maintaining both quality standards and delivery schedules.

5.Communication and Customer Support

Technical capabilities of a manufacturer become effective through their communication proficiency. Design modifications and problem-solving require clear communication to respond effectively and clarify requirements.

During manufacturer evaluations keep track of their initial interaction style. Are they quick to respond to inquiries? Is your project subject to thorough questioning by the manufacturer so they can fully grasp your requirements?

The manufacturer should assign an individual contact like an account manager or engineer to provide guidance throughout the process. The appointed individual will assist with issue resolution and production updates while keeping your project on schedule.

6.Cost vs. Value: Striking the Right Balance

While cost remains an important consideration, selecting the least expensive manufacturer can lead to negative outcomes. Providers that focus on minimizing expenses may reduce spending on materials, testing procedures, or workforce which results in quality problems that will require expensive solutions later on.

Evaluate the full range of benefits provided by the manufacturer instead of just looking at their price point. If you choose a slightly higher initial cost you will avoid problems when it results in higher quality products along with quicker delivery and fewer defects.

7.Location and Logistics

The location of a manufacturer influences logistical aspects such as lead times and shipping expenses and determines how easily you can work together. Manufacturers based domestically provide quicker results and simpler communication channels particularly when you share the same time zone. Overseas manufacturers in regions like Asia usually present cost benefits for high-volume production runs.

Evaluate your project timeline and budget before selecting between domestic and international manufacturers. When opting for an overseas partner you need to take into account shipping duration and customs rules along with potential communication challenges.

Final Thoughts

The selection process for a PCB manufacturing partner calls for thorough evaluation and investigative work. Examining technical expertise alongside quality control, supply chain reliability, scalability, communication capabilities and costs and reputation will help you identify a manufacturer who meets your project objectives. A reliable printed circuit manufacturer goes beyond PCB assembly to become a key partner who helps realize your product.

Get Your PCB Quote!