How Do You Choose Chip Inductors When Processing SMT Chip?

Get Your PCB Quote!

Table of Contents

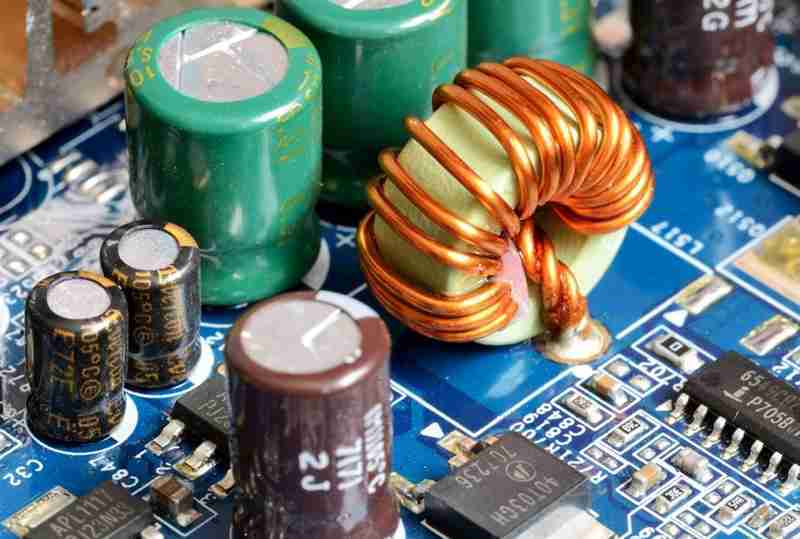

Today we will certainly discuss chip inductors. In SMT chip handling, chip inductors mostly play the role of choke, decoupling, filtering system, and tuning. There are 2 main kinds of chip inductors: winding kind and piled type. So how do you pick an appropriate chip inductor when processing SMT chips? Below are some concepts for selecting chip inductors.

1. The size of the chip inductor ought to be smaller sized than the width of the inductor to prevent extreme solder from generating extreme tensile stress and anxiety during cooling and altering the inductance value.

2. The accuracy of many chip inductors readily available on the marketplace is ± 10%. If the accuracy is called for to be greater than ± 5%, it is needed to position an order beforehand.

3. Some chip inductors can be soldered by reflow soldering and wave soldering, yet some chip inductors can not be soldered by wave soldering.

4. When fixing, you can not change the chip inductor based entirely on the inductance. You additionally require to know the functioning frequency band of the chip inductor to guarantee its working performance.

5. The shape and size of chip inductors are similar, and there are no apparent signs of the form. When by hand soldering or patching, do not make the incorrect placement or take the incorrect parts.

6. There are 3 usual chip inductors today: the initial is high-frequency inductors for microwaves. Ideal for use in regularity bands over 1GHz. The second is high-frequency chip inductors. Suitable for resonant circuits and regularity selection circuits. The third is global inductors. Generally ideal for circuits of tens of megahertz.

7. Different items have different coil diameters. The exact same inductance has various DC resistances. In high-frequency circuits, DC resistance has a great influence on Q worth, so it must be taken notice of during design.

8. The optimum current permitted to pass is likewise an indication of chip inductors. When the circuit needs to birth a large current, this indicator of capacitance have to be taken into consideration.

9. When power inductors are made use of in DC/DC converters, the size of their inductance directly influences the functioning state of the circuit. In practice, the inductance can commonly be altered by increasing or decreasing the coil to get the very best impact.

10. Wire-wound inductors are commonly made use of in interaction equipment operating in the 150 ~ 900MHz regularity band. In frequency circuits above 1GHz, microwave high-frequency inductors must be used.

The above are the leading ten considerations when choosing chip inductors in SMT chip handling. Just by better-selecting chip inductors can the top quality of SMT chip processing be better guaranteed.

Table of Contents

Get Your PCB Quote!