How SMT Circuit Boards Are Revolutionizing Surface Mount PCB Assembly

With the capacity for higher density, better performance, lower costs, and shorter turnaround times, SMT Circuit Board is widely used in electronics.

Get Your PCB Quote!

Table of Contents

In electronics, the competition to create smaller, faster, and more efficient devices is endless. The traditional, through-hole assembly method never gave us problems, but now fails in the face of modern electronics demands. Enter the world of SMT Circuit Board Technology. This method works great for placing parts right onto the board’s surface. Compact layouts, faster rates of production, and reliability are all possible with this approach, whereas the older techniques are lacking. This change is shaping the industry.

1. What Makes SMT Different?

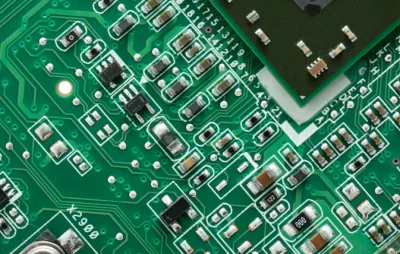

Surface mount technology places components on pads on the board without drilling holes through the board. This difference provides several huge benefits. The smaller the component, the more one can fit in a limited space. This itself leads to smaller designs, lighter weight, and less power consumption. The production times also get shortened. A machine places and solders within a much shorter time, thus improving consistency also. On the other hand, through-hole placements were much slower and manual, thus limiting flexibility.

2. Better Design Possibilities

The densities of circuits are much better with SMT. Engineers can even place components on both sides, depending on the design. Being flexible opens up some ideas, especially for multi-layer designs and complex circuitries. Devices today strongly demand high-density packaging to support such features as WI-FI, Bluetooth, sensors, and more. SMT enables these intricate assemblies without sacrificing size or performance. Consumers benefit from advanced technology packed into sleek form factors.

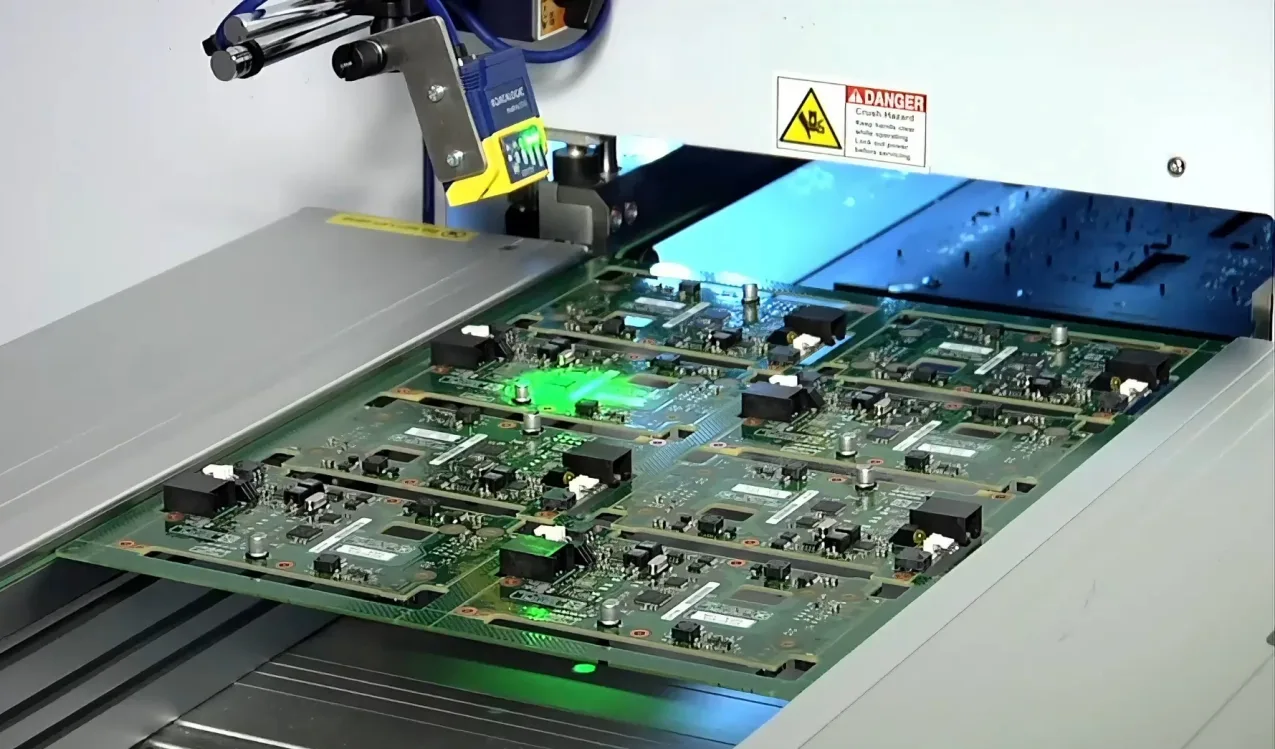

3. Faster and More Reliable Production

In manufacturing, assembling PCB Assembly lines establishes a high-speed environment to operate in. High-speed pick-and-place machines handle thousands of parts every hour with precision. The board is then taken to a reflow oven post placement so that all the connections are soldered together simultaneously. This kind of automation leads to perfect alignment and uniform solder joints. This translates to greater yield and fewer defective boards. SMT drastically increases the efficiency when compared with hand-soldering or wave soldering.

4. Cost Saving Over Time

An expensive upfront investment is needed in setting up the machinery of SMT. However, after development, the procedure results in enormous cost savings. The cost per unit becomes lower due to decreased labour and throughput increases. Smaller component sizes practically mean inexpensive logistics and cheap material usage. Fewer defective parts make returns less frequent, thereby keeping customers happy. This investment in SMT pays some healthy dividends over time, in terms of efficiency and expansion.

5. Support for Advanced Component Types

SMT provides support for advanced component packaging such as QFNs, BGAs, and micro-BGAs that have no through-hole counterpart. Such advanced packages provide an enhancement to electrical performance and thermal properties. They suit high-frequency applications, such as cellular radios and fast processors. Without SMT, integrating such parts would be impractical. The shift to SMT has enabled a new era of high-performance electronics.

6. Enhanced Quality Control

In this way, automated processes translate into good quality per board. Optical systems instantly inspect placement and soldering defects. X-rays help spot hidden issues like solder voids under BGA chips, making sure everything connects just the way it should. Defective boards get fixed before they leave the production line, thereby improving reliability and reducing failures in the field of the finished product.

7. Ideal for High Volume and Low-cost Products

SMT is a must for a product that will ship millions of units. The cost-effectiveness and speed allow for the reliable fulfilment of demand. Economies of scale also push component cost per unit down. Automated lines, being unattended, can run at a steady pace of throughput per minute. All of consumer electronics, wearables, and IoT rely on SMT for their performance, size, and cost tradeoffs.

8. Flexibility for Prototyping and Low Volume Runs

Mass production is, of course, the main beneficiary, but the newer variant of SMT also lends itself well to rapid prototyping. Flexible lines or shared services can, therefore, facilitate low-volume runs with very short turnaround. It helps designers to try new design ideas without investing in custom tooling. A prototype board can be assembled quickly into a working device ready to be tested. Such flexibility motivates innovation and shortens the development cycle of products.

9. Difficulties and Solutions in Manufacturing

SMT, as an assembly technique, does encounter some challenges. Components with ultra-fine pitch require precise placement. Even tiny misalignments will cause shorts or opens. Such assembly-induced mechanisms do become procured when there exists no inspection system. Ensure the reflow profile is properly considered to obviate problems like board warp and sallow defects. This calls for the best equipment, stringent process controls, and well-trained operators. Engineers and technicians solve these problems based on refined solder paste formulas and automated handling techniques.

10. Environmental Benefits

SMT also adds an environmental benefit. Less solder waste and the associated lower energy consumption are obvious advantages. A less insignificant component and an ion board would lessen the conversion impact. Reflow soldering consumes much less energy than wave soldering. Also, nearly 80% of SMT shops today comply with environmental regulations for lead-free solder and minimal chemical waste. With increasing green regulations, the environmental impact is diminished further with SMT being able to keep abreast with those regulations.

11. Growth Factors Behind Increasing SMT Adoption

Many factors continue to fuel the growth of SMT. The demand for smaller consumer gadgets, medical wearables, and smart sensors is on the rise, and automotive electronics are increasingly dependent on microcontrollers and sensor networks. Every industry seeks smaller and more efficient assemblies. SMT provides a clear path forward.

12. Summary

The SMT Circuit Board assembly phenomenon is far more than just a method change: it is a revolution in the general engineering field. With the capacity for higher density, better performance, lower costs, and shorter turnaround times, SMT has grown into the main assembly technology used. It manifests its utmost clear effect in prototypes or mass-based production. Therefore, with industries all eyeing to fabrication of small, smart, and green devices, SMT stands at the core of innovations.

The way forward is obvious. Unlock new frontiers of design, greater efficiencies, and walk the path of assured and predictable quality with SMT. Surface mount technology is the answer as electronics manufacturers who dare to push the envelope presently speed towards the digital world.

Table of Contents

Get Your PCB Quote!