Boosting SMT Yield: 2D vs 3D AOI Technology & Best Practices

AOI technology is a step in modern PCB assembly, crucial for ensuring product quality, improving production efficiency, and enabling intelligent manufacturing.

Get Your PCB Quote!

Table of Contents

In the highly automated PCB assembly process, a motherboard transforms from a bare board into a fully functional PCBA product through multiple precision steps, including solder paste printing, component placement, and reflow soldering. During this process, even the slightest defect—such as missed placement, incorrect components, misalignment, solder bridging, or missing parts—can cause the entire product to fail. How can these defects be swiftly and accurately detected during mass production? This is where the “quality guardian” on the production line comes into play— AOI technology.

1. What is AOI?

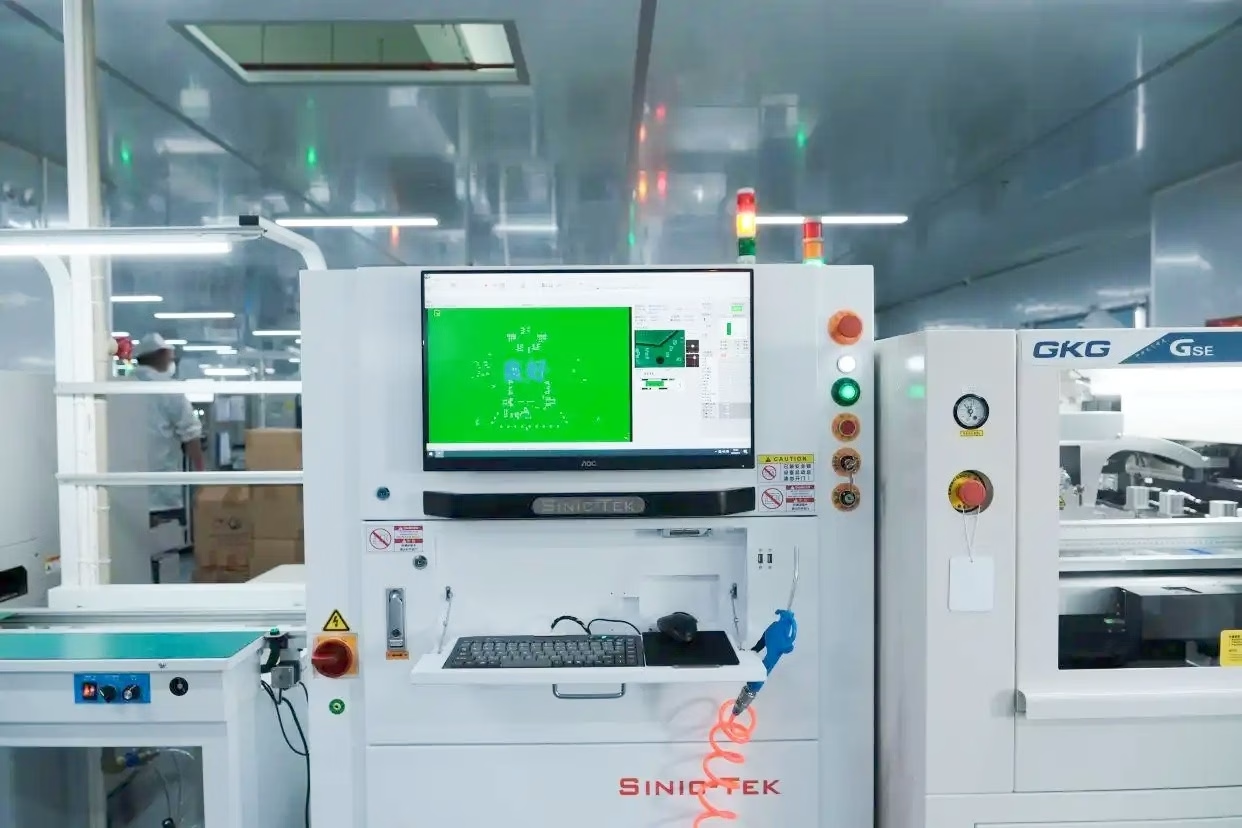

AOI (Automated Optical Inspection) is a critical step in the printed circuit board assembly (PCBA) process. This non-contact inspection method utilizes high-resolution cameras and advanced image processing software to detect and identify defects on PCBA. At PCBAndAssembly, we employ AOI systems to inspect circuit boards at various stages of the assembly process, including post-component placement and post-reflow soldering.

AOI Working Principle:

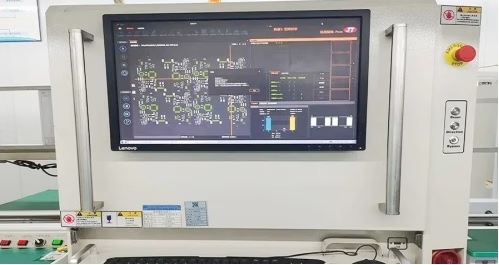

The core principle of AOI involves comparing captured PCBA solder joint images against preset standards through optical imaging and image processing technology to identify defects. Its workflow consists of four steps:

First, the AOI equipment illuminates the PCBA with RGB light sources from multiple angles, while cameras capture reflected light images. Next, the computer processes the images through noise reduction, enhancement, and other techniques. Then, solder joint quality is determined through color ratio comparison (analyzing red, green, and blue light proportions) or template matching (comparing against standard images). Finally, defects are marked and a report is generated.

Compared to traditional manual inspection, AOI offers the advantages of high speed, reliability, and continuous operation. 3D AOI technology can also effectively detect issues like PCB warping and cold solder joints—blind spots for conventional 2D inspection.

2. Why Choose AOI Technology?

AOI technology serves as an indispensable “quality gatekeeper” in PCB assembly. Through high-precision optical imaging and intelligent algorithms, it rapidly and accurately detects minute defects invisible to the human eye—such as solder joint defects, missing or misplaced components, or component misalignment. This significantly enhances inspection efficiency and product yield while reducing labor costs and rework waste.

AOI Core Advantages:

1) High Efficiency & Precision: Inspection speeds are 5-15 times faster than manual methods, identifying defects as small as 0.01mm.

2) Full Process Coverage: Spanning from pre-solder checks to post-soldering final inspections, it ensures quality control throughout the entire production flow.

3) Data-Driven Optimization: Automatically records defect data and generates reports, helping engineers quickly pinpoint process issues and transition from “post-inspection” to “process prevention.”

In short, AOI is a critical tool for ensuring PCB assembly quality, boosting production efficiency, and reducing costs.

3. What are the Types of AOI Systems?

AOI inspection machines in PCB assembly are primarily categorized as follows:

1) By production line position:

Post-Solder AOI: Installed after the screen printer. Specifically detects solder paste printing quality issues such as paste presence/absence, offset, area, thickness, and short circuits.

Pre-Reflow AOI: Installed after the placement machine and before the reflow oven. Primarily detects defects after component placement, including missing components, misalignment, tombstoning, incorrect part types, physical damage, and polarity errors.

Post-Reflow AOI: This is the most widely used AOI type. It is capable of simultaneously detecting multiple defects arising from the placement and soldering processes. These defects include solder joint shorts, cold solder joints, insufficient solder bridging.

2) By Camera Structure:

Vertical Camera AOI: Camera lens positioned perpendicular to the PCBA board surface.

Tilted Camera AOI: The camera lens is angled to facilitate inspection of component sides and solder joints.

3) By Light Source Type:

Color Lens AOI: Utilizes red, green, and blue light sources with computer-processed color ratios.

Black-and-White Lens AOI: Uses monochromatic light sources with computer-processed grayscale ratios.

4) By Equipment Operation Mode:

In-line AOI: Equipment directly integrated with the production line. PCBA flows continuously through the line, automatically diverted or advanced after inspection. This method offers high efficiency, suits mass production, and enables fully automated end-to-end inspection.

Off-line AOI: Equipment operates independently. Manual loading of PCBA for inspection is required, followed by manual unloading after inspection. This method offers high flexibility, facilitating focused inspection of specific board types or repaired boards, but efficiency is relatively lower.

5) Classification by Inspection Principle:

2D AOI: Primarily identifies defects through two-dimensional image comparison. This is the most widely used technology, effectively detecting the most common placement and soldering defects.

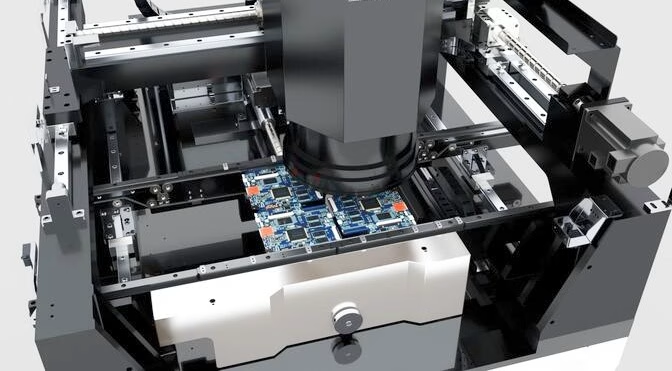

3D AOI: Combines optical imaging with blue-light laser 3D contour measurement technology to provide volumetric information about solder joints. It offers higher coverage and accuracy for micro-components (e.g., 01005) and complex packages (e.g., BGA), excelling particularly in detecting three-dimensional parameters like joint volume and height.

Laser AOI: It is capable of detecting height information, but it features complex programming and slower speeds. It is currently the most expensive AOI system, but offers the highest reliability and precision, even detecting voids within solder joints.

4. Comparison of AOI with Other Inspection Methods

Currently, inspection technologies applicable to PCB assembly can be primarily categorized into: Automated Optical Inspection (AOI), Automated X-ray Inspection (AXI), In-Circuit Testing (ICT), Flying Probe Testing, and Functional Testing (FT). Among these, AOI is the only technology capable of real-time, inline application while simultaneously reflecting trends in SMT process variations. While AOI dominates PCB assembly, each inspection method has distinct advantages, making the choice dependent on specific requirements.

AOI vs. Manual Visual Inspection

AOI operates 5–15 times faster than manual inspection, detecting defects on a board in 10–30 seconds compared to 3–5 minutes for manual inspection. In terms of precision, AOI can detect defects as small as 0.01 mm — ten times finer than manual inspection (0.1 mm) — with a significantly lower error rate. AOI is also more consistent, as it follows pre-set algorithms to ensure uniform standards. Human inspectors, on the other hand, are susceptible to mood and fatigue. However, manual inspection retains cost advantages for small batches and simple PCBA.

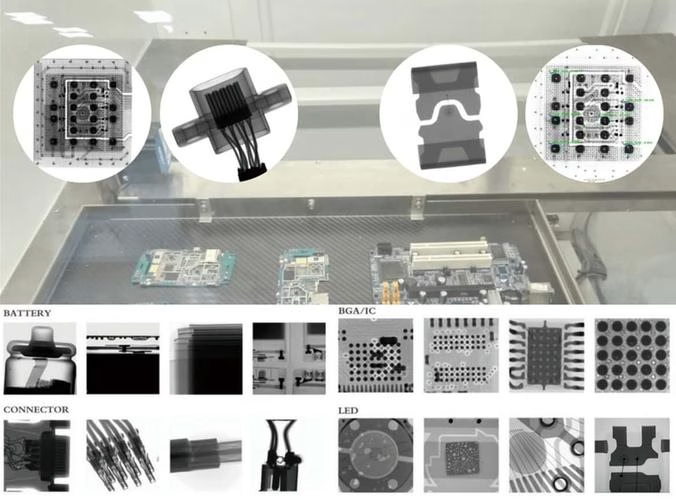

AOI vs. X-Ray Inspection

AOI can only detect surface-visible solder joints and is ineffective for joints beneath packages like BGAs or QFPs. X-ray inspection penetrates packaging to reveal internal joint conditions, making it the core technology for detecting internal defects in high-density PCBA (e.g., IC carrier boards). However, X-ray equipment is more costly and operates at relatively slower speeds.

AOI vs. Flying Probe Testing

AOI excels at detecting visual defects like open circuits, short circuits, and component misalignment. Flying probe testing focuses on electrical performance verification, confirming whether an AOI-detected “break” is truly open or a “short” is genuinely conductive. In terms of efficiency, AOI is faster (10-30 seconds per board), while flying probe testing requires 1-2 minutes per board. Typically, AOI is used for rapid screening in mass production, while flying probe testing is employed for sample verification or secondary confirmation of suspected defects identified by AOI.

In a word, AOI technology is merely a tool for fault detection and quality monitoring—not a universal solution for enhancing product quality. One should not expect automatic quality improvement simply by adopting AOI. Only by organically integrating the AOI system into the PCB assembly production and management workflow can the true benefits of this technology be effectively realized.

5. The Importance of AOI in PCB Assembly

AOI plays a critical role in PCB assembly. By leveraging high-speed imaging and intelligent algorithms, it replaces manual labor for high-precision, high-efficiency defect detection. This core technology ensures product quality, enhances production efficiency, and reduces costs.

1) Enhance inspection efficiency and reduce labor costs

Traditional manual inspection relies on visual observation, which is susceptible to fatigue, experience variations, and other factors, leading to increased missed defect rates and low efficiency. AOI equipment rapidly scans PCBA using high-resolution cameras and compares them against preset standard images. It enables 24/7 continuous operation, achieving inspection speeds far exceeding manual capabilities. This makes it particularly suitable for mass production of high-density, miniaturized PCBA (e.g., mobile phone motherboards, industrial control equipment).

2) Precisely identify defects to reduce rework waste

Through optical imaging and algorithmic analysis, AOI technology detects microscopic defects invisible to the naked eye, including but not limited to:

Soldering Defects: cold solder joints, bridging, cold solder balls, voids, etc.

Component Issues: misplacement, missing components, polarity errors, tombstoning, sideways placement, etc.

Solder Paste Printing Problems: uneven thickness, positional shifts, printing omissions, etc.

3) Optimize production processes to enhance overall efficiency

AOI equipment serves not only for final inspection but can also be integrated into production lines for real-time monitoring, ensuring quality control at every stage:

Post-Solder Inspection: Checks solder paste volume and offset to prevent bridging or cold solder joints;

Pre-Reflow Inspection: Monitors reflow oven temperature zone parameters to guarantee soldering quality;

Post-Reflow Inspection: Identifies complex defects like missing components or incorrect polarity.

4) Support quality traceability to meet high-reliability demands

During AOI inspection, data for each PCBA board (e.g., images, defect types) is archived to meet quality traceability requirements in high-reliability industries like medical and aerospace. The AOI system automatically records defect types, locations, and frequencies, generating SPC (Statistical Process Control) reports. This helps engineers quickly identify process weaknesses (e.g., insufficient placement machine accuracy, abnormal reflow oven temperature zones) to prevent defects rather than address them after the fact.

6. What are the Inspection Precautions for AOI?

In PCB assembly, AOI inspection is a critical step for quality assurance. Pay special attention to the following points during operation:

1) Pre-Startup Preparation

Ensure the power cord is securely connected and the work surface is clean. Always wear an anti-static wrist strap before operation to prevent static damage to circuit boards. After powering on, wait for the system self-test to complete and verify all indicator lights are functioning normally.

2) Equipment Calibration and Adjustment

Select the appropriate inspection program based on the product type. Enter the calibration interface. Place the standard sample in the inspection area and click the auto-calibration button. The equipment will automatically adjust light intensity and camera focus. After calibration, save the parameters and name the file for future reference.

3) Key Parameter Settings

Set detection sensitivity according to specific product process standards. For example, the sensitivity of solder joint inspections should be set to between 75% and 85% in order to balance the risks of missed defects and false positives. When using the region selection tool, make sure that the detection area covers all critical component leads and leaves a 0.5 mm buffer zone at the edges.

4) Inspection Process Operations

Place the PCBA steadily onto the conveyor track, ensuring alignment holes are properly positioned. After initiating the inspection program, closely monitor the real-time imaging display for any stuttering. If the equipment triggers an alarm, immediately pause the process. Use the magnifier function to locate the defect position and manually record the defect type and coordinates.

5) Result Handling and Standards

Passed products should be moved to the green-marked area, while non-conforming (NG) items should be placed in the red isolation box. When exporting inspection reports from the system, name files by batch number and include the inspector’s name and date. If three consecutive defects occur at the same location, immediately notify the production line technician to adjust the pick-and-place machine parameters.

6) Shutdown and Maintenance

After closing the inspection program, wait until the fan has completely stopped before disconnecting the main power supply. Use a lint-free cloth dipped in a dedicated cleaning agent to wipe the camera lens and light source module. Clean debris from the track gaps using cotton swabs. Calibrate equipment accuracy weekly using a calibration plate. Contact the manufacturer for maintenance if the error exceeds 0.02mm.

7) Safety Precautions

Never open protective covers or insert hands into the inspection area while the equipment is operating. If smoke or unusual noises are detected, immediately press the emergency stop button and disconnect the main power switch. When cleaning with alcohol, operate at least 3 meters away from the equipment to prevent liquid splashing onto circuit boards.

8) Common Issues and Solutions

If character detection yields excessive false positives, continuously update component library parameters and reduce the number of key characters for detection. When detection blind spots occur, optimize PCB layout by prioritizing surface-mount devices and ensuring at least 3mm of process margin between components and PCB edges.

7. Future Development Trends of AOI Technology

AOI is evolving toward greater intelligence and efficiency, such as through AI-driven smart inspection, predictive maintenance, and flexible inspection technologies to further optimize production processes. For electronics manufacturers, selecting AOI applications suited to their production models—such as pre-solder inspection for high-volume production and post-solder inspection for low-volume, high-mix production—is crucial.

8. PCB Assembly AOI Technology FAQs

Automated optical inspection (AOI) is a machine-based technique used to test and check PCBAs for potential errors, such as surface defects, dimensional defects, and component placement defects.

AOI is based on automated image processing, supported by optical sensors and machine evaluation algorithms. The goal is to automate quality assurance, accelerate processes, and detect errors with the highest accuracy.

AOI is exceptionally useful in maintaining quality standards, especially in high-speed manufacturing lines where manual inspection is impractical.

The core of an AOI system is to acquire high-definition images of the object under inspection using an optical system, and then use image processing algorithms to compare these images with a standard template to identify defects.

9. Summary

AOI technology serves as the “quality guardian” for PCB assembly. Through high-speed, high-precision optical scanning and intelligent algorithms, it detects minute defects such as component misalignment and solder bridging 24/7. This enhances efficiency while reducing missed defect rates, enabling a leap from manual sampling to fully automated process prevention. It safeguards the manufacturing of smart electronic products. With continuous technological advancements, AOI will propel the PCB assembly industry toward higher quality and greater efficiency.

Table of Contents

Get Your PCB Quote!