PCB Assembly Manufacturing In The Medical Industry

Get Your PCB Quote!

PCB assembly manufacturing will become increasingly important in the medical business as the population ages. PCB circuit boards, for instance, are essential components of cardiac monitoring equipment like pacemakers and medical imaging units like MRI. Even responsive neurostimulators and body temperature monitoring devices can use the most cutting-edge PCB components and technology. Thus, the importance of PCB assembly manufacturing in the medical sector will be the topic of discussion today.

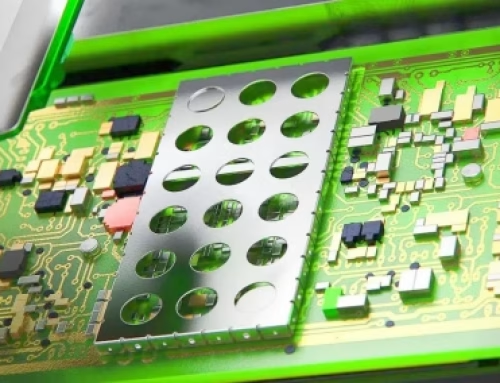

1. Characteristics of Medical PCB Boards

Biological tests, medical devices, and equipment like ventilators, hemodialysis machines, sphygmomanometers, electronic gastroscopes, electrocardiographs, and medical monitors all commonly employ medical PCB boards. Because medical devices have high requirements for precision, stability, safety, dependability, and other circuit board qualities, medical PCB boards must follow strict quality control and safety standards throughout the design and manufacturing processes.

High reliability: Medical PCB boards need to be highly reliable in order to meet the long-term stable functioning requirements of medical equipment.

High precision: To guarantee the accuracy and zero error of medical equipment, the internal structure of medical PCB boards needs to be constructed properly.

High safety: Medical PCB boards should be able to effectively avoid circuit overheating, excessive current, and excessive voltage issues.

High degree of customization: Medical PCB board engineers need to be very flexible to meet the requirements of different medical equipment.

Sterility or antibacterial: Medical PCB boards must possess sterile or antibacterial qualities in order to successfully stop bacterial transmission and cross-infection.

Environmental protection: Environmentally acceptable materials and a pollution-free manufacturing method are essential for medical PCB boards.

2. Application of PCB in the Medical Industry

Advanced medical technology is like a beacon in the current medical profession, illuminating the path for disease diagnosis, treatment, and rehabilitation. The printed circuit board, or PCB, that is concealed inside these medical devices functions as a precise cornerstone, discreetly carrying intricate circuit systems, guaranteeing the steady operation of medical equipment with great accuracy and dependability, and playing a crucial part in preserving life and health.

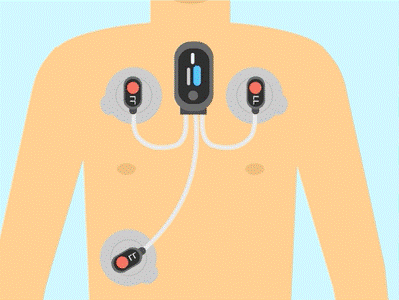

1) Wearable Medical Devices

The market for wearable medical technology is now expanding at a rate of over sixteen percent annually. Furthermore, without sacrificing precision or robustness, medical gadgets become lighter, more compact, and more comfortable to wear. Online motion sensors are used by many of these gadgets to gather pertinent data, which is subsequently sent to the proper medical specialists. The best medical devices available already have incredibly strong functions, and some of them can even tell when a patient’s wound is infected. The realization of these functions is precisely the design innovation of the scientific researchers behind them and the technical support of the PCB manufacturing industry.

The market for senior care will continue to expand as the population’s aging trend intensifies. As a result, as the population ages, wearable medical technology will become increasingly popular in the home and senior care sectors in addition to the traditional medical industry.

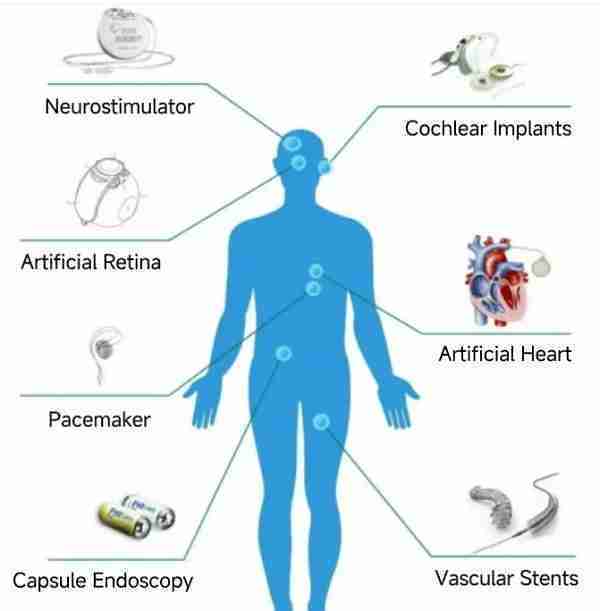

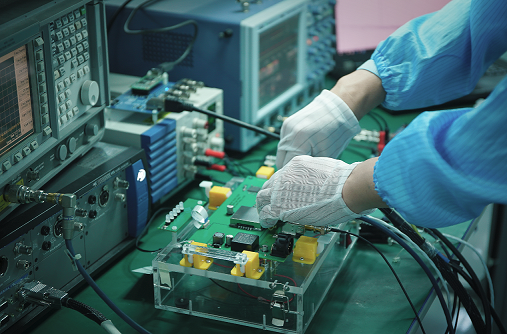

2) Implantable Medical Devices

Since there isn’t a single standard that all PCB assemblies must follow, using PCB assembly in implanted medical devices becomes more difficult. In other words, different implants will accomplish different objectives for various medical conditions, and the design and production of PCB boards will be impacted by the unstable nature of implants.

For instance, cochlear implants enable the deaf and mute to hear thanks to the production of precise PCB circuit boards. Additionally, implanted defibrillators and other devices can help those with advanced cardiovascular disease. So in this area, the PCB manufacturing industry has higher efficiency to be developed.

3) Cardiovascular Health Medical Devices

In the past, many electronic records lacked any kind of connectivity, and cardiac health record device integration was extremely subpar. Rather, each system operated independently, managing documents, orders, and other duties uniquely. These systems have been combined over time to create a more complete interface, which has further increased productivity by allowing the medical sector to examine patient medical care status more quickly.

4) Medical Sterilization Equipment

The epidemic has gradually eased in 2022, and many public places have begun to reopen. People are returning to work after a long period of isolation and embargo. As a result, it is crucial to clean and sanitize the surroundings in which people live, not just in hospitals but also in other sizable public areas like businesses, schools, and subway stations. People’s risk of contracting infections and viruses will also rise due to the extensive cross-contact of people in these areas. The development and manufacture of sterilization equipment and systems can solve these problems well. Advanced disinfection robots can perform multiple disinfections for 24 hours, purify the air, and comprehensively improve work efficiency. At the same time, they can also strengthen epidemic prevention measures in public places.

5) Mobile Medical Facilities

Conventional cables and cords have rapidly become obsolete due to the development of PCB assembly technology. While wires and cords were frequently plugged into and unplugged from conventional power outlets in the past, contemporary medical advancements enable physicians to provide patient care at any time and from any location. Given that smartphones, iPads, and other such devices make it simple for healthcare providers to acquire and transmit critical medical information when needed, the mobile health market was actually valued at over $20 billion a few years ago. With only a few mouse clicks, patients may now acquire equipment and drugs, fill out paperwork, and study-specific symptoms or disorders, all made possible by advancements in mobile health.

3. Summary

The medical industry has a very close connection with PCB assembly production. It is impossible to separate PCB manufacturing technology and design solutions from essential medical instruments and equipment. The high-quality standards observed by the medical market have also indirectly promoted the technological development of the PCB manufacturing industry.

Pcbandassembly provides a one-stop PCB assembly service. We are one professional company from PCB manufacturing to Electronic Components Sourcing to PCB Assembly for more than 12 years! Our Printed circuit boards are widely built into robotics, medical, automobile, communication, industry and consumer electronics, and so on. We also offer top-notch hardware production and processing services to smart hardware companies worldwide!

Get Your PCB Quote!