Prepreg and Core: Their Role in PCB Manufacturing

The guide explores the roles of prepreg and core, analyzing their compositions, properties, and how they work in concert to form a robust and functional PCB. At PCBAndAssembly, we translate these complex material synergies into manufacturing excellence, providing world-class multilayer PCB solutions that power today's most demanding innovations.

Get Your PCB Quote!

Table of Contents

- 1. რატომ პრეპრეგ და ძირითადი ნივთიერება PCB-ებში?

- 2. პრეპრეგის გაგება: წებოვანი ფენა

- 3. სტრუქტურული ხერხემალი

- 4. პრეპრეგ vs. ბირთვი

- 5. PCB Stackup-ის შექმნა: ფენა-ფენა მიდგომა

- 6. მასალის შერჩევის კრიტიკული მოსაზრებები

- 7. გავლენა PCB-ის მუშაობასა და საიმედოობაზე

- 8. PCB წინასწარი დაპრეგაცია და PCB ბირთვი კითხვა-პასუხიs

- 9. რეზიუმე

- ძირითადი Takeaways

1. Why Prepreg and Core Matter in PCBs?

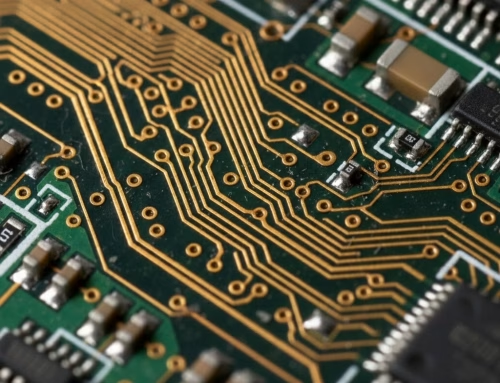

In the intricate world of modern electronics, Printed Circuit Boards(PCBs) serve as the fundamental platforms that connect and support countless components. From the simplest single-layer board to the most complex, high-performance multilayer masterpiece, the choice and understanding of materials are paramount. Among these critical materials, prepreg and core stand out as the foundational elements that dictate a PCB’s performance, reliability, and manufacturability. For engineers and designers, distinguishing between these two isn’t merely a technical detail; it’s the bedrock for creating PCBs that meet stringent electrical, thermal, and mechanical demands. As devices continue to miniaturize and performance expectations soar—driven by advancements like 5G, IoT, and high-speed computing—the significance of selecting the right materials for your PCB stackup has never been greater.

This article dives deep into the roles of prepreg and core, breaking down their compositions, properties, and how they work in concert to form a robust and functional PCB. Understanding these two essential PCB layer stackup materials is crucial for anyone involved in PCB manufacturing, design, or engineering, ensuring the production of high-quality, reliable circuit boards.

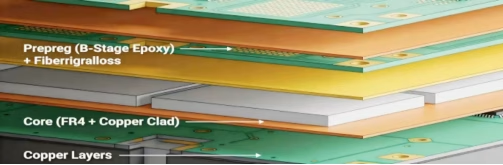

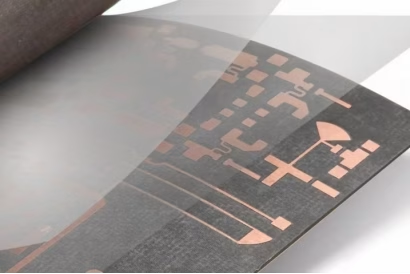

2. Understanding Prepreg: The Adhesive Layer

Prepreg, short for “pre-impregnated”, is a composite material pivotal in PCB manufacturing. It primarily consists of a woven fiberglass cloth that has been pre-coated with a partially cured thermoset resin, typically epoxy. The key characteristic of prepreg is its B-stage curing. This means the resin is only partially cross-linked, leaving it in a semi-solid, tacky state. This unique property allows the prepreg to be flexible and relatively easy to handle during the PCB lamination process.

2.1 Composition and Curing Stage

- Fiberglass Fabric:Provides mechanical strength and dimensional stability. The weave pattern and thickness of the fiberglass can vary, influencing the final dielectric properties and mechanical characteristics of the PCB.

- Resin System:Commonly epoxy, but other resins like polyimide, BT-epoxy, or cyanate ester are used for specific applications(e.g., high-frequency, high-temperature). The resin acts as the dielectric material and the adhesive that bonds layers together.

- B-Stage Curing:The resin is partially cured, making it malleable. When subjected to heat and pressure during lamination, the resin melts, flows, fills voids, and then fully cures(cross-links) to form a solid, rigid dielectric layer, bonding adjacent layers of the PCB.

2.2 Role in PCB Stackup

In a multilayer PCB, prepreg serves multiple vital functions:

- Adhesive:It acts as the “glue” that bonds copper foil layers and core layers together, forming a monolithic structure.

- Dielectric:Once cured, it becomes an insulating layer, providing electrical separation between different conductive layers. Its die lectric properties(like dielectric constant, Dk, and dissipation factor, Df) are crucial for signal integrity, especially in high-speed applications.

- Filling Voids:During lamination, the flowing resin fills any empty spaces, ensuring a solid, void-free structure, which is critical for reliability.

3. The Structural Backbone

The core material, in contrast to prepreg, is a fully cured laminate that forms the primary structural backbone of a PCB. It also consists of a fiberglass fabric impregnated with a resin, but unlike prepreg, it is supplied as a rigid sheet, often with copper foil already clad on one or both sides. This pre-clad copper is where the conductive traces, pads, and planes are etched.

3.1 Composition and Curing Stage

- Fiberglass Fabric:Similar to prepreg, fiberglass provides mechanical strength and stability.

- Resin System:Fully cured, meaning the resin has undergone its complete cross-linking process during manufacturing. This gives the core its rigidity and stable electrical properties.

- Copper Cladding:Cores are typically supplied with copper foil laminated onto one or both surfaces. This copper layer is essential for creating the conductive circuitry of the PCB.

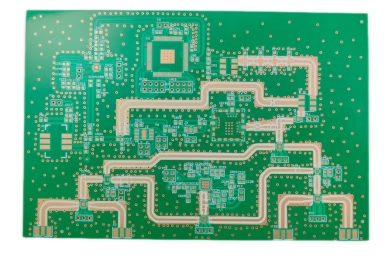

3.2 Role in PCB Stackup

Core materials play several critical roles:

- Structural Support:As a rigid, fully cured material, the core provides the main mechanical integrity and stiffness to the PCB.

- Controlled Impedance:The consistent thickness and dielectric properties of the core material are crucial for maintaining controlled impedance in transmission lines, which is vital for signal integrity in high-frequency designs.

- Ground and Power Planes:Core layers are often used for stable ground and power planes, providing consistent reference voltages and current paths.

- Pre-Etched Layers:For multilayer PCBs, inner copper layers are typically fabricated on core materials. These inner layers are etched with circuitry before being combined with prepreg and other layers in the lamination process.

4. Prepreg vs. Core

While both prepreg and core are fundamental dielectric materials in PCB manufacturing, their distinct characteristics and roles define their usage. Here’s a comparative look:

| Feature | Prepreg | Core |

| Curing Stage | Partially cured(B-stage); resin flows and fully cures during lamination. | Fully cured(C-stage); rigid and stable before lamination. |

| Physical State | Flexible, tacky sheet, often resembling a mat. | Rigid, solid laminate sheet. |

| Copper Cladding | Typically no copper cladding, used to bond copper foil or core layers. | Comes with copper foil already laminated on one or both sides. |

| Primary Role | Acts as an adhesive to bond layers and fill voids; provides dielectric separation. | Provides structural integrity and controlled dielectric thickness for etched circuitry. |

| Usage in Stackup | Used between copper layers, or between core layers and copper foils, to bond them. | Forms the internal layers(with etched copper) and outer layers(before final etching) of a multilayer PCB. |

| Thickness Control | Thickness varies slightly as resin flows during pressing. | Precise, consistent thickness is manufactured prior to lamination. |

| Material Cost | Generally less expensive per unit thickness than core. | Often more expensive due to copper cladding and manufacturing process. |

5. Crafting the PCB Stackup: A Layer-by-Layer Approach

The combination of prepreg and core materials is what allows for the creation of multilayer PCBs. A PCB stackup refers to the arrangement of copper layers and insulating dielectric layers(prepreg and core) that make up the board. The design of this stackup is a critical engineering task, directly impacting the board’s electrical performance, thermal management, and mechanical robustness.

Consider a typical 4-layer PCB. It usually begins with a central core layer, copper-clad on both sides. This core provides the initial structural integrity and holds the inner signal or power/ground layers. On top and bottom of this central core, layers of prepreg are placed, followed by outer copper foil layers. During lamination, heat and pressure cause the prepreg to melt, flow, and then cure, permanently bonding the copper foils to the central core.

For more complex PCBs with 6, 8, or even more layers, the pattern repeats: core layers with etched circuitry are interleaved with prepreg layers, which then bond to additional copper foils or other core layers. This careful layering and lamination process results in a unified, multi-layered board capable of routing complex signals without interference.

The precise arrangement and thickness of prepreg and core layers are engineered to achieve specific dielectric properties and maintain strict controlled impedance for high-speed signals. A poorly designed stackup can lead to signal loss, crosstalk, and electromagnetic interference(EMI) issues, while an optimized stackup enhances signal integrity and overall performance.

6. Critical Considerations for Material Selection

Choosing the right prepreg and core materials is crucial for meeting the performance requirements of a PCB. Several factors influence this decision:

- Dielectric Constant(Dk):Also known as εr, Dk impacts signal propagation speed and controlled impedance. Lower Dk values generally lead to faster signals. Materials with stable Dk across frequency and temperature are preferred for high-frequency applications.

- Dissipation Factor(Df):Also known as loss tangent, Df measures the energy loss in the dielectric material. Lower Df values are critical for high-speed and RF designs to minimize signal attenuation.

- Glass Transition Temperature(Tg):This is the temperature at which the resin changes from a rigid, glassy state to a softer, rubbery state. A higher Tg is important for boards operating in high-temperature environments or undergoing multiple reflow cycles.

- Decomposition Temperature(Td):The temperature at which the material starts to decompose. A higher Td indicates better thermal stability.

- Coefficient of Thermal Expansion(CTE):The rate at which a material expands or contracts with temperature changes. Matching CTEs between different materials in the stackup is important to prevent delamination or warping, especially in components like BGAs.

- Thermal Conductivity:The ability of a material to conduct heat . Materials with higher thermal conductivity can assist in thermal management, dissipating heat away from active components.

- Moisture Absorption:High moisture absorption can degrade dielectric properties and lead to reliability issues.

- Cost:Performance often correlates with cost. Balancing technical requirements with budget constraints is always a consideration.

- Manufacturability:The ease with which a material can be processed(drilled, etched, laminated) without issues.

For high-speed digital and RF applications, specialized low-loss prepreg and core materials(e.g., those with modified epoxy, polyimide, or hydrocarbon-ceramic resins) are often chosen over standard FR-4 to preserve signal integrity and minimize loss.

7. Impact on PCB Performance and Reliability

The meticulous selection and proper layering of prepreg and core materials directly influence several key aspects of PCB performance and long -term reliability:

- Signal Integrity and Impedance Control:The precise thickness and consistent dielectric properties(Dk and Df) of the prepreg and core layers are critical for maintaining controlled impedance in transmission lines. Any deviation can cause signal reflections, degradation, and crosstalk, especially in high-speed digital circuits. Proper material selection ensures clean signal propagation.

- Thermal Management:The thermal properties of the dielectric materials, such as Tg, Td, and thermal conductivity, affect how effectively heat is dissipated from active components. Materials with superior thermal performance help prevent hot spots, improve component lifespan, and ensure stable operation under various thermal loads.

- Mechanical Robustness and Reliability:The strength of the bond created by the prepreg and the inherent rigidity of the core contribute to the overall mechanical stability of the PCB. Well-matched CTEs prevent issues like delamination, warping, and solder joint stress, which can lead to premature board failure over its operational life. The consistent thickness and uniformity of the dielectric layers also contribute to the board’s structural integrity against mechanical stress and vibration.

- Electromagnetic Compatibility (EMC):A well-designed stackup using appropriate prepreg and core materials can help contain electromagnetic fields within the board, reducing unwanted radiation and susceptibility to external interference. This is crucial for meeting regulatory standards and ensuring reliable operation in crowded electromagnetic environments.

8. PCB Prepreg and PCB Core FAQs

No, they serve distinct roles. Prepreg is designed to be adhesive and fill voids during lamination, while core provides structural rigidity and pre-defined dielectric thickness, often with copper already present. Trying to interchange them would result in a non-functional or unreliable PCB.

Different applications require specific electrical, thermal, and mechanical properties. Standard FR-4(Flame Retardant type 4) is common for general-purpose boards. High Tg materials are for high-temperature applications. Low loss(low Df) materials are essential for high-frequency and high-speed designs to minimize signal attenuation and improve signal integrity.

Material thickness directly influences trace impedance, capacitance, and signal propagation delay. Thinner dielectric layers can increase capacitance and lower impedance, while thicker layers do the opposite. Precise thickness control of both prepreg and core is vital for achieving desired electrical characteristics and controlled impedance.

9. Summary

Prepreg and core materials are the fundamental building blocks of Printed Circuit Boards, each contributing uniquely to the final product. Prepreg, a partially cured composite of fiberglass and resin, acts as the adhesive and dielectric filler, bonding layers together during the lamination process. Core, a fully cured, rigid laminate often with pre-clad copper, provides the structural backbone and forms the primary dielectric layers for circuitry. Their combined use in a carefully designed PCB stackup is essential for achieving the required electrical, thermal, and mechanical performance. Understanding their differences and selecting the appropriate types based on dielectric properties, thermal characteristics, and cost is critical for producing high-quality, reliable, and high-performing PCBs in today’s demanding electronics landscape.

Key Takeaways

- Prepreg is the “glue”:Partially cured(B-stage) resin + fiberglass, used for bonding and dielectric separation in multilayer PCBs.

- Core is the “backbone”:Fully cured(C-stage) laminate + fiberglass, usually copper-clad, providing structural rigidity and stable dielectric properties.

- Stackup is crucial:The arrangement of prepreg and core layers directly impacts signal integrity, controlled impedance, and thermal management.

- Material selection matters:Factors like Dk, Df, Tg , and CTE must align with application requirements(e.g., high-speed, high-temp) to ensure reliability.

- Not interchangeable:Prepreg and core have distinct roles and cannot be swapped without compromising board functionality and performance.

Table of Contents

- 1. რატომ პრეპრეგ და ძირითადი ნივთიერება PCB-ებში?

- 2. პრეპრეგის გაგება: წებოვანი ფენა

- 3. სტრუქტურული ხერხემალი

- 4. პრეპრეგ vs. ბირთვი

- 5. PCB Stackup-ის შექმნა: ფენა-ფენა მიდგომა

- 6. მასალის შერჩევის კრიტიკული მოსაზრებები

- 7. გავლენა PCB-ის მუშაობასა და საიმედოობაზე

- 8. PCB წინასწარი დაპრეგაცია და PCB ბირთვი კითხვა-პასუხიs

- 9. რეზიუმე

- ძირითადი Takeaways

Get Your PCB Quote!