SMT Stencils Acceptance and Storage Management Instructions

Get Your PCB Quote!

Table of Contents

1. The acceptance of new stencils shall be the responsibility of engineering and technical personnel, and shall be carefully checked according to the standards of the photolithography files and inspection reports provided by the supplier.

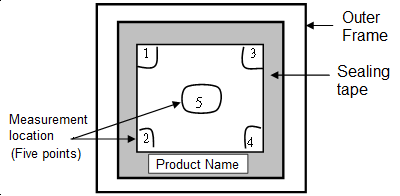

2. Before the acceptance of new stencils and their use in production, the stencils must be tension tested. The test shall comply with the following requirements: five test points shall be selected for confirmation, four of which are located at the four corners of the mesh cabinet, and the midpoint of the distance from the center of the stencils to the edge of the stencils shall be used as the test point; the central test point shall be based on the exact center of the stencils.

The tension standard of the new stencils should meet the following requirements: When the size is 55*65, it should not be less than 40 Newtons per centimeter; When the size is 42*52, it should not be less than 35 Newtons per centimeter. During use, the tension standard of the SMT stencils should meet the following requirements: when the size is 55*65, it should not be less than 30 Newtons per centimeter; when the size is 42*52, it should not be less than 25 Newtons per centimeter. In addition, the maximum difference between the tension test results should be controlled within 10 Newtons per centimeter.

3. After the new stencils are accepted by the engineering staff, the stencils administrator will be notified to paste the stencils label. If the acceptance is unqualified, it must be returned to the supplier for processing.

4. The stencils provided by the customer need to be confirmed by the engineer for appearance, and the administrator is responsible for testing the tension of the stencils and recording the test results in detail. If any problems are found, feedback should be given to the customer immediately.

5. The production department will uniformly number and register the qualified stencils and properly store them in the designated location of the stencils rack. To ensure the distinction, different customers’ stencils are placed in separate areas with clear markings.

Shenzhen SMT processing factory: Each compartment of the stencil frame can only accommodate one stencil, and it must be ensured that the stencils can be accessed without hindrance.

Table of Contents

Get Your PCB Quote!