Teflon PCB: Why PTFE Is Essential for High-Frequency Electronics

Teflon PCBs are specialized boards with PTFE as the dielectric material, designed for high-frequency, high-temperature and chemically challenging applications.

Get Your PCB Quote!

Table of Contents

- 1. PCB phủ Teflon là gì?

- 2. Các đặc tính vượt trội của bảng mạch PTFE

- 3. Những ưu điểm và nhược điểm chính của mạch in Teflon

- 4. Các ứng dụng đa dạng của mạch in Teflon

- 5. Những điểm phức tạp trong quá trình chế tạo và sản xuất PCB Teflon

- 6. Teflon so với FR-4: So sánh các vật liệu

- 7. PCB Teflon FAQs

- 8. Tổng kết

In the dynamic world of electronics, the pursuit of higher speeds, greater miniaturization, and enhanced reliability places immense demands on printed circuit boards (PCBs). These silent workhorses form the backbone of virtually all electronic devices, dictating performance and longevity. While various materials serve as substrates for PCB, one stands out for its superior properties in demanding applications: Teflon. This guide delves into the intricate details of Teflon PCB, exploring their unique characteristics, myriad advantages, and critical applications that make them indispensable for cutting-edge technology.

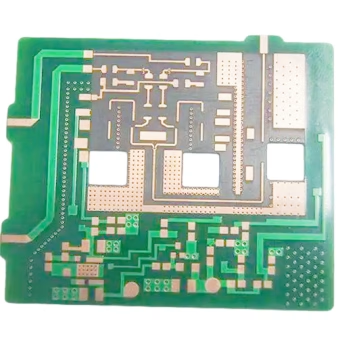

1. What is a Teflon PCB?

The choice of PCB material is paramount in modern electronics, especially for the high-frequency applications. Among the various substrates available, the Teflon PCB stands out as a superior solution for demanding environments. Often referred to as PTFE PCB or Teflon printed circuit board, these boards utilize polytetrafluoroethylene (PTFE) as their primary dielectric material.

Teflon, a fluoropolymer renowned for its exceptional non-stick properties in kitchenware, possesses an equally impressive set of electrical, thermal, and chemical characteristics that make it ideal for advanced electronics. Unlike conventional PCB materials like FR-4, Teflon PCB boards are engineered to excel in scenarios where signal integrity, minimal loss, and environmental stability are non-negotiable.

2. Unrivaled Properties of PTFE Circuit Boards

The widespread adoption of PTFE circuit boards in critical applications is primarily due to their exceptional material properties. These characteristics enable superior performance, particularly at high frequencies and in harsh operating conditions.

1) Electrical Properties

- Low Dielectric Constant (Dk):PTFE boasts an exceptionally low Dk, typically ranging from 2.0 to 2.2. This property is crucial for high-frequency circuits as it allows for faster signal propagation speeds and reduced signal delay. Lower Dk also contributes to better impedance control, a vital aspect for maintaining signal integrity in sensitive designs.

- Low Dissipation Factor (Df)/Loss Tangent:The Df of PTFE is remarkably low, often below 0.002. This minimizes signal loss, making it an ideal choice for RF , microwave, and millimeter-wave applications where signal attenuation can severely impact performance. High-frequency signals lose less energy as heat, ensuring more efficient power transmission.

- Stable Dk and Df Across Frequencies and Temperatures: One of PTFE’s most significant advantages is the stability of its Dk and Df across a wide range of frequencies and temperatures. This ensures consistent electrical performance, preventing signal degradation or impedance shifts under varying operational conditions.

2) Thermal and Mechanical Properties

- High-Temperature Resistance:PTFE can withstand very high operating temperatures, typically up to 260°C (500°F), without significant degradation. This makes Teflon PCBs suitable for applications exposed to extreme heat.

- Excellent Thermal Stability:Its thermal stability ensures that the board dimensions and electrical properties remain consistent across varying temperatures, which is critical for reliability.

- Low Moisture Absorption:PTFE exhibits extremely low moisture absorption, typically less than 0.01%. This prevents changes in electrical properties due to humidity, ensuring stable performance in moist or humid environments.

- Chemical Inertness:Teflon is largely chemically inert, making it highly resistant to a wide array of chemicals, solvents, and corrosive agents. This enhances the durability and lifespan of the Teflon printed circuit board in harsh chemical environments.

- Dimensional Stability:While pure PTFE can be soft, laminates often incorporate fillers (like woven fiberglass or ceramic particles) to enhance mechanical rigidity and dimensional stability, making them more suitable for PCB manufacturing processes.

3. Key Advantages and Disadvantages of Teflon PCBs

Understanding the pros and cons helps in deciding if a Teflon PCB is the right choice for a given project.

1) Advantages

- Superior High-Frequency Performance:Unmatched signal integrity and minimal loss for RF, microwave, and high-speed digital circuits.

- Excellent Thermal Management:Ability to operate reliably in high-temperature environments.

- High Reliability:Stable electrical properties across wide frequency and temperature ranges, coupled with chemical resistance and low moisture absorption, lead to highly reliable boards.

- Reduced Signal Distortion:Low Dk and Df minimize crosstalk and signal dispersion, crucial for high-speed data transmission.

- Long Lifespan:Resistance to environmental factors ensures a longer operational life.

2) Disadvantages

- Higher Cost:Teflon PCB manufacturing is generally more expensive than producing standard FR-4 boards due to the specialized materials and fabrication processes required.

- Fabrication Challenges:PTFE is a soft material, making drilling, plating, and etching more challenging. Specialized equipment and expertise are needed.

- Mechanical Properties:Pure PTFE can be mechanically less rigid than other substrates, necessitating the use of fillers or specialized construction techniques to improve rigidity and handle ability.

- Limited Availability:Not all PCB manufacturers have the capability or experience to produce high-quality PTFE circuit boards, leading to a smaller pool of specialized Teflon PCB suppliers.

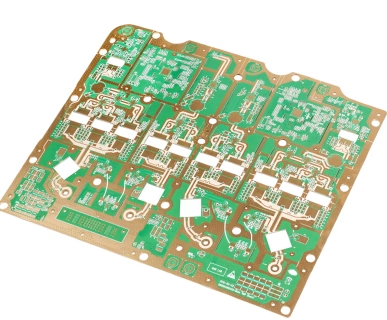

4. Diverse Applications of Teflon Printed Circuit Boards

The unique properties of Teflon printed circuit boards make them indispensable in industries where performance cannot be compromised. Their ability to handle high frequencies and harsh conditions opens up a wide array of applications:

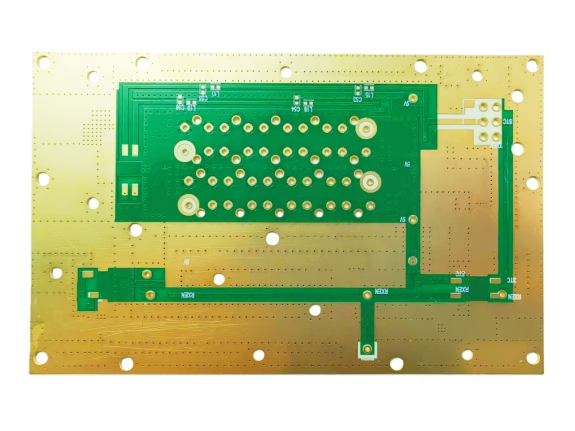

1) RF and Microwave Communications: This is the primary domain for Teflon PCBs. They are crucial for antennas, power amplifiers, filters, mixers , and oscillators in radar systems, satellite communication, cellular base stations, and wireless infrastructure.

2) High-Speed Digital Circuits: For very high-speed data transmission lines where signal integrity and minimal signal loss are critical, such as in advanced computing, telecommunications backplanes, and data centers.

3) Aerospace and Defense: Used extensively in avionics, missile guidance systems, military radar, and electronic warfare systems due to their reliability, temperature stability, and resistance to harsh environments.

4) Medical Equipment: In high-frequency diagnostic equipment, imaging systems, and precise instrumentation where consistent electrical performance is vital.

5) Test and Measurement Equipment: For high- precision testing apparatus that requires stable impedance and low signal loss to accurately characterize devices and systems.

6) Automotive Radar: As advanced driver-assistance systems (ADAS) become more sophisticated, PTFE PCBs are used in automotive radar modules.

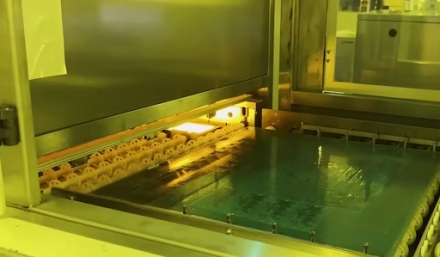

5. The Intricacies of Teflon PCB Fabrication and Manufacturing

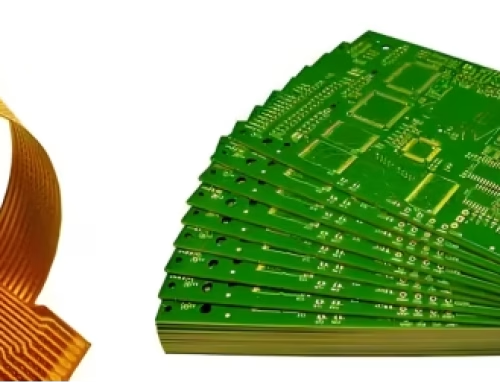

The manufacturing process for a Teflon PCB is significantly more complex and specialized than that for conventional FR-4 boards. Teflon PCB fabrication requires meticulous attention to detail and specialized techniques to overcome the inherent challenges presented by the PTFE material.

Key Fabrication Challenges:

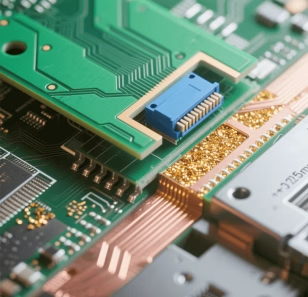

1) Drilling: PTFE is soft and tends to smear during drilling, which can contaminate hole walls and impede subsequent plating processes. Specialized drill bits, drilling parameters (speed, feed rate), and desmear processes are essential to ensure clean, plateable holes.

2) Plating: Achieving strong adhesion between copper and the non-stick PTFE surface is difficult. Chemical etching processes are often used to create microscopic roughness on the PTFE surface, improving copper adhesion. Plasma treatment can also be employed to enhance surface wettability and adhesion.

3) Etching: While etching the copper layers is similar, careful control is needed to prevent over-etching or undercutting, which can be exacerbated by the material’s properties.

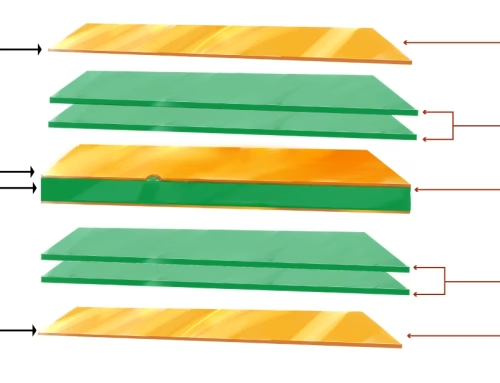

4) Lamination: Multi-layer PTFE circuit boards require precise lamination processes. The low softening point of some PTFE laminates and their specific thermal expansion characteristics necessitate specialized pressing cycles. Fillers, such as woven glass or ceramics , are often incorporated into PTFE laminates to improve mechanical stability and reduce z-axis expansion.

5) Material Handling: Due to the softness of pure PTFE, careful handling is required throughout the Teflon PCB production process to prevent damage or deformation.

Many Teflon PCB suppliers invest in advanced machinery and highly skilled technicians dedicated solely to high-frequency and PTFE-based PCB manufacturing to address these challenges. The selection of specific PTFE laminates, which often contain ceramic fillers, woven fiberglass, or combinations thereof, is crucial as these fillers significantly impact the mechanical properties, Dk stability, and manufacturability of the final board.

6. Teflon vs. FR-4: A Material Comparison

To fully appreciate the role of Teflon PCB, it’s beneficial to compare it with FR-4, the most common PCB material.

| Feature | Teflon PCB (PTFE) | FR-4 PCB (Epoxy/Glass) |

| Dielectric Constant (Dk) | Low (2.0-2.2), stable across frequencies | Medium (4.2-4.7), varies with frequency |

| Dissipation Factor (Df) | Very Low (typically < 0.002) | Medium (typically 0.015-0.025) |

| Frequency Range | Excellent for RF, Microwave, Millimeter-wave (>1 GHz) | Good for general purpose, low-to-mid frequency (<1 GHz) |

| Temperature Resistance | High (up to 260°C), excellent thermal stability | Moderate (up to 130°C-180°C Tg) |

| Moisture Absorption | Extremely Low (< 0.01%) | Moderate (0.1-0.2%) |

| Chemical Resistance | Excellent | Good |

| Mechanical Strength | Can be soft (improved with fillers) | High, rigid |

| Cost | High | Low |

| Fabrication Complexity | High, specialized processes required | Standard, widely available |

| Typical Applications | Radar, Satellite, 5G, High-speed Digital, Test & Measurement | Consumer Electronics, Industrial Controls, General Computing |

While FR-4 is cost-effective and suitable for a vast majority of electronic devices, its electrical performance degrades significantly at higher frequencies due to increased Dk and Df. For applications demanding precision, high frequency, and reliability in extreme conditions, the superior properties of Teflon printed circuit board justify its higher cost and manufacturing complexity.

7. Teflon PCB FAQs

The primary advantage is its superior electrical performance at high frequencies, characterized by a very low dielectric constant (Dk) and dissipation factor (Df), which minimizes signal loss and ensures excellent signal integrity.

Not typically. While PTFE is the base material, most PTFE circuit boards incorporate fillers like woven fiberglass or ceramic particles to enhance mechanical strength, dimensional stability, and improve manufacturability.

The softness of PTFE can lead to drilling smear, and its non-stick nature makes achieving reliable copper adhesion difficult during plating. Specialized equipment, chemical treatments, and precise process controls are required.

They are predominantly used in RF and microwave communications, aerospace and defense (radar, avionics), high-speed digital computing, and advanced test and measurement equipment.

Teflon PCBs exhibit excellent thermal stability and can withstand much higher operating temperatures (up to 260°C) without significant degradation or changes in electrical properties, unlike many other PCB materials which might show performance shifts.

8. Summary

The Teflon PCB, also known as PTFE PCB, represents a pinnacle in PCB materials, offering unparalleled performance for high-frequency, high-temperature, and chemically challenging applications. Its core strength lies in its exceptionally low and stable dielectric constant and dissipation factor, coupled with high-temperature resistance, minimal moisture absorption, and chemical inertness. These properties make it the material of choice for critical components in RF communications, radar systems, aerospace electronics, and high-speed digital infrastructure.

While Teflon PCB manufacturing presents significant challenges in terms of drilling, plating, and lamination due to the unique characteristics of PTFE, the investment in specialized processes and expert Teflon PCB suppliers is justified by the superior reliability and performance these boards deliver. When compared to conventional FR-4, PTFE circuit boards excel where signal integrity and environmental robustness are paramount, positioning them as essential components in the advancement of cutting-edge electronic technologies.

Table of Contents

- 1. PCB phủ Teflon là gì?

- 2. Các đặc tính vượt trội của bảng mạch PTFE

- 3. Những ưu điểm và nhược điểm chính của mạch in Teflon

- 4. Các ứng dụng đa dạng của mạch in Teflon

- 5. Những điểm phức tạp trong quá trình chế tạo và sản xuất PCB Teflon

- 6. Teflon so với FR-4: So sánh các vật liệu

- 7. PCB Teflon FAQs

- 8. Tổng kết

Get Your PCB Quote!