What Are the Advantages and Disadvantages of Single-Layer PCBs?

Get Your PCB Quote!

Table of Contents

PCBs are used to sustain and link electric elements in electronic products. They are generally made from copper, material, and substratum. The efficiency and strength of a PCB are straight related to its size and number of layers. Including even more layers to a PCB raises its capability. This has substantial advantages in the electronics industry.

1. Single Layer PCB

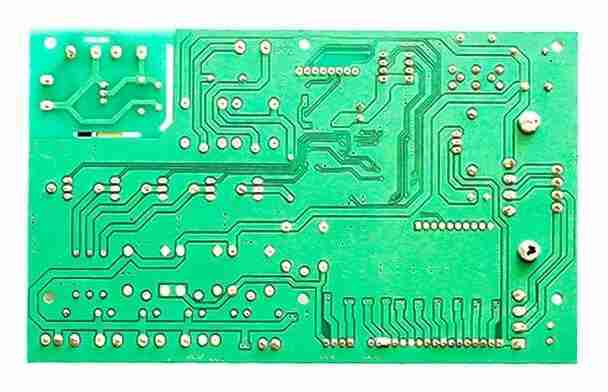

A single-layer published circuit board (PCB) is a kind of motherboard that has only a slim covering of conductive product (generally copper) on one portion of the board. The various other portion functions as a connection factor for various electronic components.

Consequently, electric borders, fills, ports, parts, cables, placing holes, vias, and pads are all manufactured utilizing a single-layer PCB substrate, a conductive metal layer, a silk screen, and a protective solder mask.

Regardless of the introduction of advanced innovations, the electronics industry still relies heavily on single-layer PCBs.

2. Advantages of Single Layer PCB

Inexpensive of SMT manufacturing

Less complicated to establish and less prone to mistakes

Since there is only one layer, soldering, placing, and electronic boring elements are easy.

Excellent selection for minimal layouts

Cost-effective for automation of consumer electronics

Finest selection for quick, automation.

3. Downsides of Single Layer PCB

The benefits of single-layer PCBs are that they are straightforward and low-cost to produce. But they additionally have some disadvantages that customers ought to know.

Absence of room and pins for links on published motherboard where numerous parts are needed.

Reduced speed and efficiency.

As capability increases, weight and size additionally increase, reducing the portability of the gadget.

Table of Contents

Get Your PCB Quote!