Flexible PCB Design and Manufacturing: A Guide to PCB Circuit Board Creation

Get Your PCB Quote!

Table of Contents

The rapid evolution of the world in which we live has given birth to flexible PCBs as the modern frontrunner in the creative trend. These flexible circuits constitute future modern essentials, versatility offerings, and reliability standards for the applications of technology. They have revolutionized the design and implementation of circuits from smartphones to medical devices.

Understanding Flexible PCB Technology

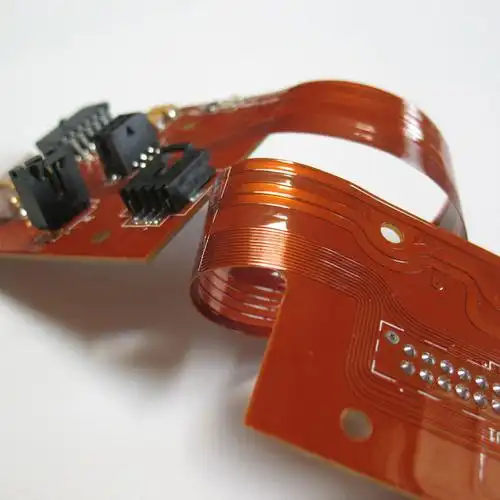

These PCBs or flex circuits are made of materials that last bending and twisting. They are made from flexible substrates like polyimide or polyester as opposed to rigid boards. Thus, here morphs a new horizon of compact yet unusual designs. These flexible wonders allow manufacturers to produce electronic gadgets that are lighter, smaller, and more efficient than ever.

These PCBs are, by and large, found in industries other than one. They are found in aerospace, automotive systems, consumer electronics, and even wearable technologies. There are simply innumerable uses for them due to their changing shapes and movements.

The Importance of PCB Circuit Board Design

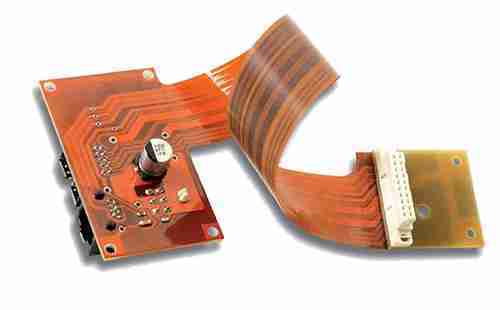

This is the first indispensable step in the manufacturing process, designing effective PCB circuit board designs. The performance and behavior of circuits to a device depend on the way in which it is designed. Flexible PCB circuits are to be designed by special techniques to take care of bending and movement.

The components and routing must be arranged so carefully that they don’t get damaged from stress. In addition, thermal and electrical integrity are the other key consideration factors in design. Software advancement was by precision and efficiency, enabling flexibility circuit manufacturers to meet most critical requirements for efficient designs.

Challenges in Manufacturing Flexible PCBs

Manufacturing these PCBs is embroiled in challenges. The materials tend to be delicate and hence the processes involved require much precision. To be able to work on thin substrates without causing tears and defects is a task that calls for great expertise.

Ensuring consistent quality becomes another big challenge. Most of the circuits have critical applications such as those in medical devices, and thus any possible defects can have dire consequences. Therefore, PCB manufacturers have to ensure that stringent quality control measures are laid down to ensure reliability in the performance of such circuits.

Choosing the Right PCB Manufacturer

The right manufacturer would be critical in the production of great flexible PCB. Such frameworks are certainly not available as a capability to every manufacturer because they may lack experience in handling such circuits’ phenomenal requests. Therefore, it’s important to find a manufacturer who understands the nuances in the design and production.

Quality manufacturers would bring the whole process from the beginning to end, from the first designs to the parts where these PCBs end. They will use advanced technology equipment and material to make sure that circuits are durable and its functions become almost perfect. Working with an experienced team could make a difference between the success and failure of your project.

Applications of Flexible PCBs

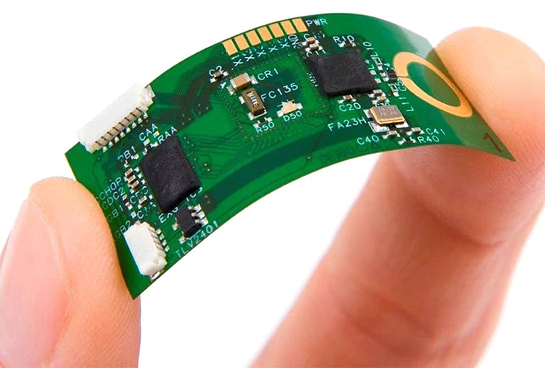

These PCBs have the same flexibility in application as rigid ones. In medicine, they enable small diagnostic devices and smaller wearable health monitors. Tight spaces in a car are used for sensors and control units.

From a foldable smartphone to a gaming device, flexible printed circuit boards are used in consumer electronics. These PCBs are required in industrial equipment where durability and restructuring are required. Their ability to maintain performance under extreme conditions sets them apart from traditional rigid boards.

Trends in PCB Circuit Board Creation

The PCB designing and manufacturing sector is ever-emerging nowadays. One of the material trends is to have some additional features integrated with advanced materials, making circuits more flexible and reliable. Automation technology is now being looked into for simplifying production and thus incurring lesser costs and more efficiency.

Sustainability has now become a priority; the search for greener materials and processes is on its way. Another trend would be the use of artificial intelligence in design and testing, which will allow faster development cycles and improved performance.

Future Prospects for Flexible PCBs

With the pace of advancement in technology, the future holds many opportunities for the flexible circuit board. It is being synonymized with the requirement of such circuits for new classes of applications and systems such as smart sensors and concept-to-market robotics, resulting from continuous modernization in production practices. The role of these circuits in next-generation devices will only continue to grow with time, cementing them as one of the defining elements of long-lasting electronics.

The Core Advantage of Flexible PCB Technology

This PCB technology gives a high degree of adaptability to today’s electronics that allows an innovator to design solutions that traditional rigid boards cannot achieve. Light, and flexible enough to bend, it is most suited to small-dimension and dynamic applications, such as foldable smartphones and medical implants, which use the aforementioned technology to maximize utility while utilizing minimum space. Examples of reinforcement, such as using polyimide materials to ensure durability while remaining flexible, provide further evidence of a future in which these circuits become the incumbent in innovation-driven industries.

Precision in PCB Circuit Board Design

There is more to precision in PCB circuit design. Designing a PCB circuit board is all about enhancing its flexibility. It is a perfect case in which every approach to designing a circuit board is applicable. Stress distribution and electrical integrity in boards must be accounted for by engineers throughout the entire course of designing a circuit. Apart from advanced software tools, which have now made it very easy for the designer to refine and test configurations digitally before manufacturing any tangible products, that patience will minimize the risk of failure and maximize efficiency.

Final Thoughts

Creating a flexible PCB circuit board from design to manufacture is quite complicated but very interesting. It has this quality because flexibility has helped to change the way circuits are built into devices, making them dynamically flexible. The right manufacturer can help assure that your project meets the highest standards in terms of quality and innovation. For companies and engineers planning to tap the potential of these PCBs, this is the right time because it is no longer looking at reality but at the future.

You are ready to ride the new wave of technology in electronics, not just for meeting today’s requirements, but for the future itself.

Table of Contents

Get Your PCB Quote!