A Complete Guide to Aluminum PCB

Explore the complete guide to aluminum PCB, including types, benefits, and top applications for aluminum circuit boards in modern electronics.

Get Your PCB Quote!

Table of Contents

Many sectors are now implementing this strategy with a strong emphasis on resilience and effective heat management. These circuit boards are a great choice for high-power electronics, especially when keeping heat under control is a top priority. They help keep components cool and running safely. This guide divides aluminium PCB into topics like construction and typical applications.

1. What Makes Aluminum PCBs Different?

In comparison with the conventional fiberglass-based boards, aluminum circuit board designs contain a metal base. This foundation is generally made of aluminum alloy and serves as a heat sink, useful for environments wherein components generate considerable heat.

Their structure includes a special thermal layer between the copper circuit and an aluminium base, built to move heat away quickly. Its primary function is to enhance heat transfer so components can operate efficiently for a longer period.

2. Why Choose Aluminum-Based Boards?

In terms of high-powered applications, the aluminum pcb board type has a definite edge. It achieves this by conductively transferring the heat away, so sensitive devices, such as LED lighting and power converters, do not overheat.

Another benefit is mechanical stability. Their physical stress resisting ability is enhanced as compared to traditional FR4 boards. Hence these are useful for harsh environments such as industrial machines or outdoor systems, which have their share of vibrations and shocks.

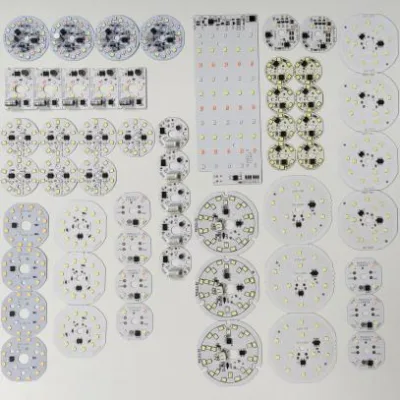

3. Types of Aluminum Circuit Boards

Several aluminium circuit board structures exist depending on the needs. Some are flexible and are considered for curved surfaces; while some are multi-layered for more complicated usages. Some common types include single-layer, double-layer, and multi-layer.

Every type of PCB has the brief of potentialities. The single-layer PCB is a cheap type and simple to apply, whereas the multilayer PCBs are used in more advanced electronic assemblies.

4. Manufacturing Process

There are few unique steps in making aluminum printed circuit boards. The process starts with the etching of the copper layer to fabricate circuit paths. A dielectric layer is laid onto the aluminum core, and this is followed by solder masking and surface finishing.

Being thermally sensitive, the choice of materials for manufacturing and the manufacturing process becomes very important. Proper process control ensures that the board’s heat resistance and electrical performance are maintained.

5. Common Applications

In the lighting area, demand for PCB aluminium led systems is high. Rejection of heat becomes paramount for the LEDs to maintain brightness and life. This is where these boards shine.

Other use cases include power supplies, automotive systems, audio devices, and communication equipment. These are areas where both thermal efficiency and reliability are crucial.

6. Advantages Over Traditional PCBs

This clearly explains why centres for engineers select aluminium LED PCB solutions under high-stress conditions. Thermal management is still the most important one, followed by increased durability and reduced rate of component failures.

The concept of aluminum also weighs less compared to other materials, which helps reduce total product weight in automotive and aerospace industries.

7. Aluminum Core PCB and Its Role

An aluminum core PCB increases rigidity and conduction. The core finds its application in multilayer circuits that require a solid thermal mass on one side. It offers a good trade-off between system complexity and cooling efficiency.

The core serves as a mechanical support structure of the PCB while heat is conducted away from hotspots by the aluminium material. It is found in applications in telecom and industrial automation sectors.

8. What to Look for in a Manufacturer

Finding a dependable aluminum PCB manufacturer is of prime importance. Good Aluminum PCB integrates acceptable materials and fabrication processes with quality and rigorous testing of the product in each step.

Pick a partner mindful of technical requirements and compliance standards. These are essentially the criteria for performance and safety, whether consumer gadgets or heavy equipment are being procured.

Customisation and Support: Owing to technical expertise, the choice ought to be done with flexibility in design and tailored production offered. Every project has its own requirements-whether in size, layer count, or thermal performance-which means the partner should be in a position to adapt.

9. Exploring Backed PCB Options

Since aluminum backed PCB designs dissipate heat more efficiently, an increasing number of engineers are going for this option. The boards have a full aluminum layer under the circuitry, which serves as an integral heat sink preventing heat buildup.

Additional backing effectively strengthens the board too, thereby enabling greater performance from the electronic device. It becomes even more apparent with high-power LED modules and power electronics.

10. Aluminium PCB FAQs

They’re typically used in areas where devices generate a lot of heat – think LED lights, power converters, or automotive parts.

It’s all about how well they manage heat. Whether it’s stronger materials, tighter design tolerances, or extra capabilities, it goes beyond what a typical PCB can do.

Yes. However, from the manufacturing point of view, multilayer ones are quite complicated, and they are used mostly for highly advanced electronics.

Yes, many manufacturers use them for end-user products like LED bulb, audio amplifiers, and even laptop adaptors.

The manufacturing, as well as material cost, may raise their cost a bit. But the long durability is a plus when it comes to cost-effectiveness.

Yes. All these boards are SMT, meaning that they are installed on modern automated assembly lines.

Given proper use and proper quality of manufacture, they would simply go on for times greater than usual boards, especially under the effect of higher temperatures.

Flexible PCB aluminum is available, though they are quite less common. They are mainly used in bendable design requirements.

11. Summary

Aluminum PCB technology is advancing and providing smart solutions for industries that need heat control and rugged design. Lighting, automotive, high-power electronics-the circuit boards produce lasting enhancements. With the increasing demand for efficiency, the need for reliable board materials is growing, and aluminum-the most viable candidate-is at the forefront of this shift.

Table of Contents

Get Your PCB Quote!