How PC Board Assembly and PCBA Circuit Board Technology are Revolutionizing Devices

PCB assembly and PCBA circuit board technology simultaneously change the way electronics are built, work, and interact with the world.

Get Your PCB Quote!

Table of Contents

Technology changes faster than what one realizes. The days are gone when patients had to carry a heavy box around wherever they went. Today, the small tablet cases or health watches can weigh an ounce, yet pack a bigger punch than force-feed clunky machines. At the heart of these things is the evolution of PCB assembly and PCBA circuit board technology. These two simultaneously change the way electronics are built, work, and interact with the world.

As we look towards the future direction of electronics, it must be borne in mind that such a trend is changing the environment around us in both the digital and physical realms.

1. The Rise of Compact Intelligence

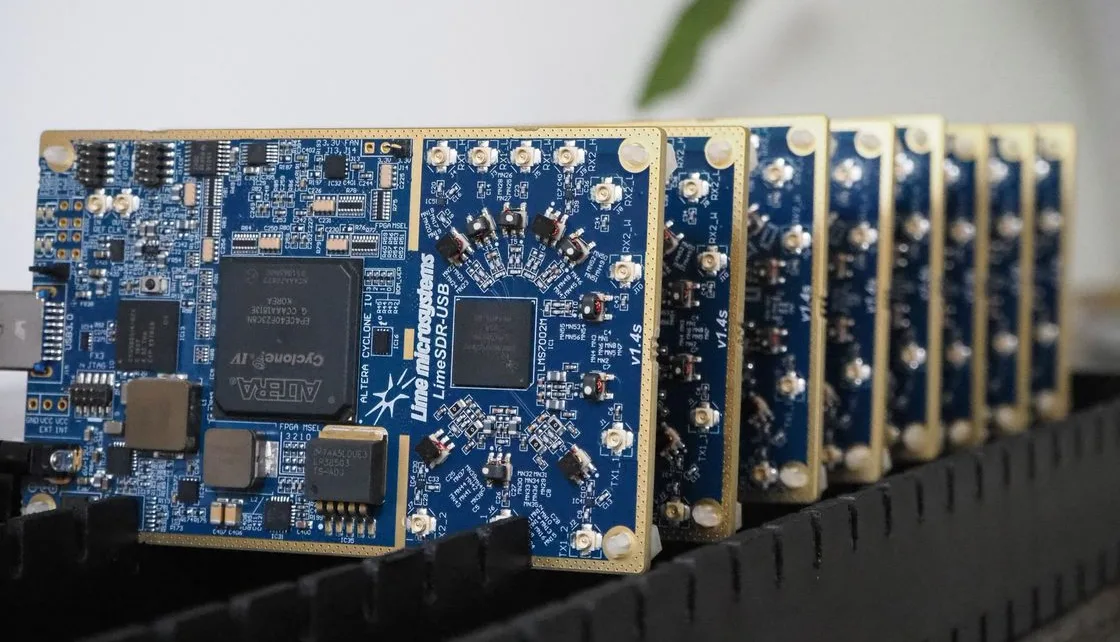

If today’s devices could be small, then they could also pack more punch. Think of your smartphones, drones, or medical implants. Their potency comes from a density of components, all tightly interlinked on extremely small circuit boards.

Such precision was impossible a few decades ago. But advances in the assembly of printed circuit boards now allow complex designs to be produced at scale. Automation, precision, and smarter workflows have opened doors to electronics that perhaps were considered impossible before.

Gone are the days when these devices needed big-wires or components to operate. Everything today is embedded within and optimized for space, performance, and durability.

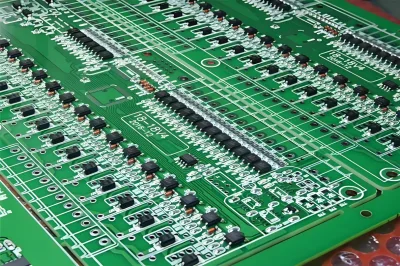

2. Improving Reliability at the Core

Dependable performance has to be the base for every electronic device. From a smartwatch that monitors your health to control systems of an aircraft, failure is not an option.

Here, modern circuit technology really makes the difference. The newer soldering methods, surface mount technology, and better board materials have created levels of reliability heretofore unattained. Each component is placed with high precision. Each and every connection goes through performance check-whether the connection stubbornly refuses.

The boards maintain their integrity even under abnormally high temperature or mechanical stress. Such stability ensures longer durability to the devices, better operational condition, and serving critical applications with confidence.

3. Streamlining Manufacturing Processes

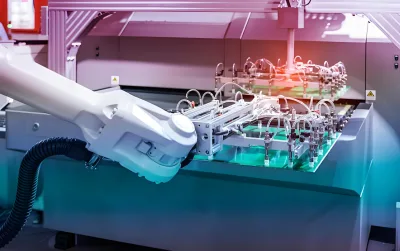

In times past, manufacturing electronic equipment was slow and very manual.

Through automation of assembly processes, boards have become manufactured consistently. When assisted by machines, the scope of human errors can be minimized. The prototyping speed has increased, allowing innovations to happen at faster intervals.

Test and quality control eliminate issues real-time, thus reducing waste and increasing yields. In effect, everything is being done to create better electronics faster and with fewer defects.

The PCBA circuit board powers the devices and makes processes efficient.

4. Supporting Innovation in Wearables and Healthcare

Health, with fit in all, changes into something wearable-device-conscious. It measures heart rate, sleep patterns, and even falls.

All these functions are possible because of miniaturised, flexible electronics. Boards can be designed to fit within curved surfaces or along with soft materials. Sensors and communication modules are embedded with great precision.

At the medical level, the same evolution is even more crucial. Life-saving implants, diagnostic tools, and remote monitoring systems rely on small boards that are highly reliable.

An advanced example of PC board assembly combines innovation in technology and careful construction oversight in the production so that the instruments can retain a greater amount of accuracy, response time, and safety in the most delicate environments.

5. Driving the Growth of Electric Vehicles and Automation

Electric Vehicle (EV) and driverless technologies have become an area of ever-growing appeal. Beneath their sleek exteriors is a world of highly sophisticated electronics.

Control units of battery management systems and driver assistance require circuits with great durability and efficiency. The systems are, most of the time, subjected to harsh environments – heat, vibration, and continuous movement.

6. Meeting Environmental and Energy Challenges

Sustainability is no longer optional. Today, devices must be excellent in their performance, consuming least power and putting forth a small footprint.

Advanced boards have given support to energy-efficient designs. They minimize power loss, maximize heat dissipation, and elongate battery life. The same is agreed to be crucial for both portable devices and big installations.

Manufacturers, on the other hand, embrace greener options; that entails something like: lead-free solder, recyclable materials, and waste-reducing methods.

Given the status quo, the role of the circuit board has also expanded. The new role does not embrace technology alone; rather, it embraces responsible creativity.

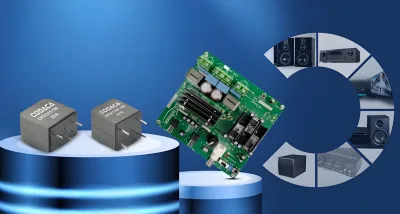

7. Supporting Customisation Across Industries

Not all devices suit the one-size-fits-all model. Different industries require different specialised functions, forms, and features.

Customised board design has never been easier. Tools now enable you to make all requirements, whether it is a rugged board for mining applications or a flexible one for wearables.

Engineers can now modify layouts; opt for customised connectors; define and optimise for expected outcomes. The assembly of printed circuit boards carves these ideas into implementable realities.

This flexibility is why we see tech entering spaces we never imagined a decade ago.

8. Empowering Education and Innovation

Besides the commercial applications, this technology further finds applications in fields of education and research.

With components being cheap, design platforms accessible, and assembly services fast, experimentation has become easy. This translates to learning, designing, and further discoveries.

Never has the journey been shorter than from conception to prototype-building. That bodes extremely well for the future of technology.

9. Redefining the Limits of What’s Possible

In the twilight of the present, everything heralds just the dawn of another epoch of innovation.

Ideas are getting closer to reality-they include flexible boards that bend like paper, circuits embedded into fabric, and self-healing. Today’s work actually sets the stage for what is to be invented tomorrow.

From smart-home applications to space technologies, the lowly circuit board is right in the heart of everything. Its progression holds the key to the digital future.

10. Final Thoughts

In an era increasingly defined by smart devices and the interconnectivity of systems, these developments in PC board assembly and PCBA circuit board technology hold the utmost importance.

They were not only forcing the good into electronics; they were redefining what electronics are capable of.

The assembly of printed circuit boards lead a secular change in industries through innovations in design, manufacture, and materials. So, for a techie or a business leader, every aspect of modern life is being touched by this technology. The next chapter of innovation starts here-small in size, but infinite in possibilities.

Table of Contents

Get Your PCB Quote!