How to Choose a PCB Board Maker for Your Circuit Board Prototype and Product Launch

Guide to choosing the right PCB manufacturer—focus on expertise, prototyping, materials, scalability, and testing for quality production.

Get Your PCB Quote!

Table of Contents

Every electronic device is dependent on the printed circuit boards (PCB) that serves as the primary component of devices that are primarily used for basic equipment as well as sophisticated industrial equipment. The progression of your venture relies on selecting the correct PCB board maker to develop either a new product or a design enhancement. Achieving better device performance depends heavily on the quality of circuit boards which also improves product longevity and accelerates time-to-market.

This guide delivers all the necessary information you need to pick the best PCB manufacturer for your prototype development and product launch.

The Role of a PCB Board Maker

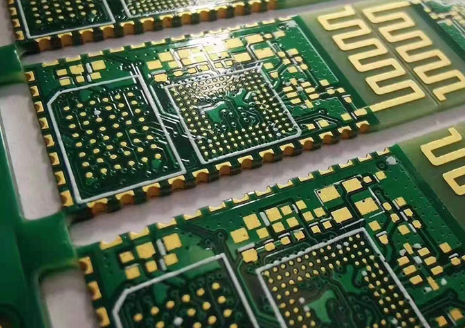

A maker represents a specialized manufacturer whose function is to construct printed circuit boards using your supplied design specifications. The process encompasses multiple stages which involve substrate preparation followed by copper layering and etching before drilling then plating and solder masking and finishing with testing.

A suitable partner will manufacture boards according to your specifications while providing technical knowledge and ensuring dependable communication along with prompt delivery. The partnership gains additional importance during the PCB prototype stage as it represents the first iteration of your circuit board intended for testing and validation before large-scale production.

When selecting the PCB manufacturer, you should take into consideration a variety of important aspect:

- Experience and Expertise

Choose a PCB manufacturer that has proven experience in the creation of circuit boards that are compatible with the complexity of your design. The manufacturers with a lot of experience are able to work with multilayer PCBs as as flexible PCBs as well as rigid-flex PCBs. They also have high-frequency boards. The expert know-how of the manufacturer can help to minimize mistakes in production while making sure that the design is optimised to make it more efficient in manufacturing.

- Prototyping Capabilities

Prototyping is an essential stage in the development process. A skilled manufacturer must deliver precise high-grade circuit board prototypes within fast turnaround times. With the help of rapid prototyping technology designers are able to quickly evaluate their ideas, find the issues and rectify them and then refine their designs in a timely manner, thereby saving time and money, without long delays.

Find out about their production schedules along with their minimum order requirements as well as the availability of expedited or quick-turn services. Quick iteration speeds can greatly enhance your development cycle effectiveness.

Knowing their capabilities for testing like electrical tests, both AOI and Xray inspections is vital to ensure the PCBs are free of defects.

- Material and Technology Options

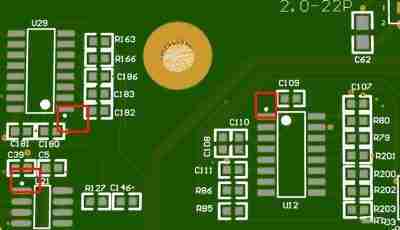

Your circuit design dictates which substrate materials (such as FR4, polyimide) or surface finishes (such as HASL, ENIG, OSP) you will require. The PCB provider must present multiple material selections and maintain expertise in cutting-edge production methods.

High-performance boards require specialized manufacturing techniques such as laser drilling or controlled impedance routing together with blind/buried vias. The manufacturer must possess adequate technical capabilities to carry out these particular processes.

- Production Flexibility and Growth Potential

Assess your current production needs while determining your capability to expand operations when market demand rises. PCB manufacturing companies often focus exclusively on large volume production or specialize in low-volume prototyping. Select a PCB manufacturer that supports prototype requirements and adjusts production capacity for your product launch.

Selecting a partner that manages small prototype runs alongside large production batches streamlines your process and sustains product consistency throughout its lifecycle.

- Pricing and Lead Times

Although cost plays a significant role, choosing the cheapest provider may lead to quality compromises. When comparing quotes from multiple makers make sure to consider what is included in each price such as testing services shipping fees and support options.

The duration it takes to complete processes becomes crucial during prototyping phases because design changes occur often. Select a maker that offers fair prices while delivering dependable delivery schedules to prevent setbacks in your development timeline.

- Customer Support and Communication

You must maintain strong communication with your PCB manufacturer to ensure a successful partnership. A good manufacturer needs to respond quickly to communications and discuss technical matters while actively working to resolve potential problems.

Online portals from some manufacturers enable customers to track orders and upload design files which enhance transparency and process efficiency. Effective customer service helps avoid misunderstandings which could result in expensive errors.

The Importance of Testing in

The physical proof of concept for your design comes in the form of a PCB prototype. At this point theoretical concepts transition into practical applications. Rigorous testing throughout the prototyping phase must be performed to uncover electrical faults and mechanical fit issues along with thermal problems.

Tips for Working with Your PCB Manufacturer

To get the most from your collaboration:

- Provide clear and complete design files: Your PCB manufacturer requires design files in standard formats like Gerber files that come with comprehensive fabrication instructions.

- Communicate your requirements: Your design specifications should include material choices and mechanical tolerances along with testing requirements from the start.

- Request samples: Request sample boards from the manufacturer to assess quality before you place sizeable orders.

- Plan for iteration: The prototype development process will involve multiple refinement stages with the help of a cooperative manufacturer.

Preparing for Product Launch

After your prototype passes testing and validation you must start planning for full-scale production. Your choice of maker needs to demonstrate seamless capabilities in moving from prototype development to large-scale production.

Validate their production capabilities along with supply chain dependability and quality standards before ordering large quantities. Evaluate production run lead times and shipping logistics to prevent launch phase bottlenecks.

Conclusion

When you evaluate experience together with prototyping abilities, quality standards, materials, pricing and support your design will transform into a high-quality reliable product with ease.

The collaboration with your PCB manufacturer throughout every step from initial prototyping to final production will determine whether your project stays on schedule and within budget.

Seek out experienced professionals who provide comprehensive PCB manufacturing expertise and prototype services when you need a dependable partner throughout your entire manufacturing process.

Table of Contents

Get Your PCB Quote!