SMT & THT PCB Assembly: Prototype to Low Volume Selection

One-stop PCBA services: Full Turnkey, SMT pick-and-place, and wave soldering. Specialized in flexible/wearable devices with 24h quotes for prototypes.

Get Your PCB Quote!

The journey from a circuit design concept to a functional electronic device hinges significantly on one crucial stage: PCB Assembly. More than just soldering components onto a board, PCB assembly is a meticulous process that combines precision engineering, advanced manufacturing techniques, and rigorous quality control to bring electronic circuits to life. It’s where the bare bones of a PCB transform into the beating heart of countless gadgets, from simple consumer electronics to complex industrial systems and innovative wearable technology.

This comprehensive guide delves into every facet of PCB assembly, offering insights into the core processes, various service models, considerations for different production volumes, and the unique demands of specialized applications like flexible and wearable devices. Whether you’re a product designer, an engineer, or simply curious about how electronics are made, understanding PCB assembly is essential for appreciating the intricate world of modern technology.

1. What is PCB Assembly?

PCB assembly, often referred to as PCBA, is the process of populating a bare printed circuit board with electronic components to create a functional electronic assembly. This involves attaching components such as Integrated Circuits (ICs), resistors, capacitors, and connectors to the designated pads or holes on the PCB using various soldering techniques. The goal is to establish precise electrical connections that allow the circuit to operate as designed, converting a mere substrate into a functional electronic module.

2. The PCB Assembly Process : A Step-by-Step Guide

The PCB assembly process is a sophisticated sequence of steps, primarily divided between Surface Mount Technology (SMT) and Through Hole Technology (THT) components. Most modern PCBs utilize a combination of both.

2.1 Solder Paste Application

For Surface Mount Devices (SMDs), the first step involves applying solder paste—a mixture of tiny metal solder particles and flux—to the component pads on the PCB. This is typically done using a stencil and a solder paste printer, ensuring precise deposition of paste only where components will be placed.

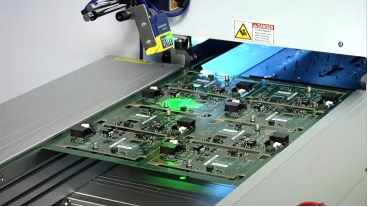

2.2 Automated SMT Component Placement (Pick and Place Process)

Once solder paste is applied, high-speed automated pick-and-place machines precisely position SMDs onto their respective pads . These machines are programmed with exact coordinates and can place thousands of components per hour with incredible accuracy.

2.3 Reflow Soldering

After component placement, the PCB moves through a reflow oven. This oven has several temperature zones that gradually heat the board, melt the solder paste, and then cool it to solidify the solder joints, forming strong electrical and mechanical connections between components and the PCB.

2.4 Through-Hole Component Insertion

Components with leads that pass through holes (THT components) in the PCB are typically inserted after SMT processing. This can be done manually or with automated insertion machines for high-volume production.

2.5 Wave Soldering

For THT components, wave soldering is a common method. The PCB passes over a “wave” of molten solder. First, flux is applied, then the board is preheated, and finally, the exposed leads and pads on the bottom of the board are soldered by the wave, creating reliable connections.

2.6 Inspection and Testing

Quality control is paramount. Various inspection and testing methods are employed:

- Automated Optical Inspection (AOI):Uses cameras to scan the board for defects like missing components, incorrect polarity, or poor solder joints.

- X-Ray Inspection:Used to inspect solder joints under components that cannot be seen with AOI (e.g., Ball Grid Arrays – BGAs).

- In-Circuit Test (ICT):Checks for shorts, opens, resistance, capacitance, and other basic electrical properties of components on the assembled board.

- Functional Test (FCT):Simulates the operational environment to verify if the board performs its intended functions.

2.7 Cleaning and Finishing

Finally, residual flux is often cleaned off the board to prevent corrosion and improve aesthetics. Conformal coating may be applied for environmental protection, and the boards are packaged for shipment.

3. Types of PCB Assembly Services

Manufacturers offer different service models to cater to varying client needs and supply chain structures.

| Feature | Full Turnkey | Consigned | Prototype |

| Who Supplies Parts? | Assembler 13 | Client 14 | Mixed 15 |

| Typical Volume | High 16 | Any | 1-10 Units 17 |

| Lead Time | Faster 18 | Longer | Very Fast 19 |

| Best For | Startups 20 | Inventory Owners 21 | R&D/Testing 22 |

3.1 Full Turnkey PCB Assembly

In a Full Turnkey PCB assembly service, the assembler handles every aspect of the project. This includes not only the assembly itself but also component procurement, bare PCB fabrication, testing, and even final box-build. This option is ideal for clients who prefer a single point of contact, streamlined logistics, and reduced management overhead. It’s particularly beneficial for startups or companies without established supply chains.

3.2 Consigned PCB Assembly

Also known as “kitted” assembly, Consigned PCB assembly means the client provides all necessary components to the assembler, along with the bare PCB boards and design files. The assembler’s role is then to simply assemble the provided materials. This is suitable for clients who have existing relationships with component suppliers, prefer to manage their own inventory , or have unique components that are difficult for external parties to source.

3.3 Partial Turnkey PCB Assembly

Partial turnkey assembly offers a hybrid approach. The client might provide some critical or specialized components, while the assembler procures the rest. This provides flexibility, allowing clients to leverage their own sourcing strengths while still offloading a significant portion of component management to the assembler. It balances cost control with convenience.

4. Assembly Volume Considerations

The volume of boards to be produced significantly impacts the choice of manufacturing processes, cost , and lead time.

4.1 Prototype PCB Assembly

Prototype PCB assembly involves producing a small batch of boards (often 1-10 units) for testing and validation. The focus here is on speed, flexibility, and accuracy, allowing designers to quickly iterate and verify their designs. Costs per board are higher due to setup charges and less optimized processes, but the overall cost for the small batch is manageable. Turnaround times are typically very fast.

4.2 Low Volume PCB Assembly

Low Volume & Prototype PCB Assembly (Kleinserie) typically refers to production runs ranging from tens to a few thousand units. This volume is common for specialized industrial equipment, niche consumer electronics, or initial market launches. While still allowing for some flexibility, it starts to benefit from automated processes, striking a balance between cost -effectiveness and adaptability. This is often an attractive option for startups seeking to scale up from prototyping without committing to mass production.

4.3 High Volume PCB Assembly

High Volume PCB Assembly involves producing tens of thousands to millions of units. This requires highly automated production lines, optimized processes, and stringent quality control to achieve the lowest possible cost per unit and maximize efficiency. The emphasis is on consistency, throughput, and minimizing defects at scale. Lead times are typically longer for initial setup but then very fast for subsequent runs.

5. Specialized PCB Assembly Types

Beyond standard rigid boards, certain applications demand unique assembly considerations.

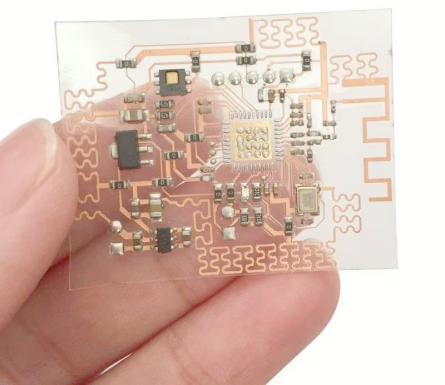

5.1 Flexible PCB Assembly

Flexible PCB Assembly deals with boards made from flexible substrate materials, allowing them to bend, twist, and conform to various shapes. This is crucial for compact devices, dynamic applications, and those requiring integration into irregular enclosures. Challenges include delicate handling to prevent damage, specialized soldering processes (often at lower temperatures), and unique tooling for pick-and-place machines. Applications range from medical devices and automotive electronics to wearables and aerospace.

5.2 Wearable PCB Assembly

Wearable PCB Assembly shares many characteristics with flexible PCB assembly due to the inherent need for miniaturization and conformity to body shapes. However, it adds further complexities:

- Miniaturization:Components are often ultra-small (01005 or even smaller) requiring extremely precise placement.

- Power Efficiency:Design and assembly must support low-power consumption.

- Robustness:Boards must withstand bending, twisting, sweat, and occasional impacts.

- Material Selection:Use of flexible or rigid-flex PCBs, specialized encapsulation materials.

- Connectivity:Integration of wireless modules, sensors, and sometimes flexible interconnects.

This segment demands the highest levels of precision and reliability for devices like smartwatches, fitness trackers, and health monitors.

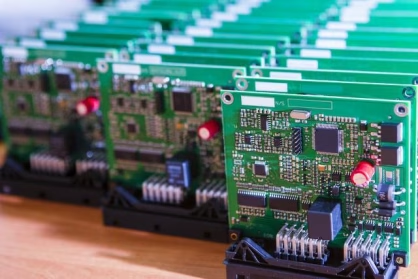

5.3 Standard PCB Assembly

Standard PCB Assembly typically refers to the assembly of rigid PCBs, which are the most common type used in a vast majority of electronic devices. While often less complex in terms of board flexibility compared to their flexible counterparts, standard PCB assembly still requires high precision, adherence to industry standards, and robust processes for SMT and THT components.

6. PCB Panel Requirement of Assembly

For efficient manufacturing, multiple individual PCBs are often fabricated and assembled together on a larger “panel.” This process, known as panelization, is crucial for optimizing production throughput and reducing costs, especially in High Volume PCB Assembly. Key requirements for PCB panels include:

- Panel Layout:Individual boards are arranged on a larger substrate with sufficient spacing between them for routing and breaking.

- Fiducial Marks:These are small copper pads or crosses used by automated equipment (solder paste printers, pick-and-place machines, AOI) for precise alignment and registration of the board. Both global (panel-level) and local (individual board-level) fiducials are often required.

- Tooling Holes:Non-plated holes on the panel edges used to precisely align the panel in manufacturing equipment.

- Breakaway Tabs or V-Grooves:Methods for separating the individual PCBs from the panel after assembly. Breakaway tabs typically have small holes (mouse bites ) to facilitate clean separation. V-grooves are scored lines that allow the panel to be snapped apart.

- Component Clearance:Ensuring sufficient clearance around the edges of each individual board and between boards on the panel to prevent interference during placement and soldering, especially for overhanging components.

- Test Points:Often incorporated into the panel design to facilitate various testing procedures.

Proper panel design is critical for DFM (Design for Manufacturability) and directly impacts assembly yield and cost efficiency.

7. PCB Assembly FAQs

SMT (Surface Mount Technology) involves components mounted directly onto the surface of the PCB, typically smaller and placed by machines. THT (Through Hole Technology) uses components with leads inserted through holes in the PCB and soldered on the opposite side.

Full Turnkey is ideal for companies seeking a single point of contact for their entire PCB manufacturing and assembly process, reducing complexity, logistics management, and potentially lead times by leveraging the assembler’s supply chain expertise.

Challenges include delicate handling to avoid damage to the flexible substrate, specialized tooling for component placement and reflow, managing heat dissipation on thin substrates, and ensuring robust connections that can withstand bending.

Prototype assembly prioritizes speed and flexibility for design validation with small batches, often incurring higher per-unit costs. High volume assembly focuses on efficiency, automation, and cost reduction for large-scale production, optimizing for throughput and consistency.

8. Summary

PCB Assembly is an indispensable stage in electronics manufacturing, transforming bare circuit boards into functional electronic modules. From the precise application of solder paste and automated component placement to rigorous inspection and testing, each step is critical for producing reliable devices. The choice of assembly service—Full Turnkey, Consigned, or Partial Turnkey—depends on a company’s internal capabilities and supply chain preferences. Furthermore, production volume dictates the manufacturing approach, ranging from agile prototype runs to highly efficient high -volume production lines.

Specialized applications, such as flexible and wearable electronics, introduce additional complexities requiring unique handling, materials, and miniaturization techniques. Understanding PCB panel requirements, including fiducial marks and breakaway methods, is also vital for optimizing manufacturing efficiency and cost. By grasping these multifaceted aspects of PCB assembly, stakeholders can make informed decisions that ensure the quality, performance, and successful market entry of their electronic products.

Our company has focused as a professional one-stop service supplier from PCB manufacturing to Electronic Components Sourcing to PCB Assembly in China for more than 14 years! Our state-of-the-art PCB assembly line are very nice, including 6 SMT lines, 2 AI automated DIP lines, and 2 manual DIP lines. If you have any PCB assembly project requirements, please feel free to send us files for a quote! Our team will do our best to support your project with the most cost-effective price and the fastest delivery time!

Key Takeaways

- PCB Assembly is the process of populating a bare PCB with components, crucial for creating functional electronic devices.

- The process involves solder paste application, SMT component placement, reflow soldering, THT insertion, wave soldering, and comprehensive inspection/testing.

- Assembly services include Full Turnkey (complete solution), Consigned (client supplies components), and Partial Turnkey (hybrid approach).

- Production volumes (Prototype, Low, High) dictate manufacturing strategies, impacting cost, speed, and automation levels.

- Flexible and Wearable PCB Assembly demand specialized techniques due to unique material properties, miniaturization, and environmental factors.

- Proper PCB panelization, including fiducials and breakaway methods, is essential for efficient and cost-effective mass production.

Get Your PCB Quote!