PCBA Conformal Coating: Material Selection & IPC Standards

PCBA conformal coating is an indispensable process for safeguarding the reliability and extending the operational life of modern electronic assemblies.

Get Your PCB Quote!

Table of Contents

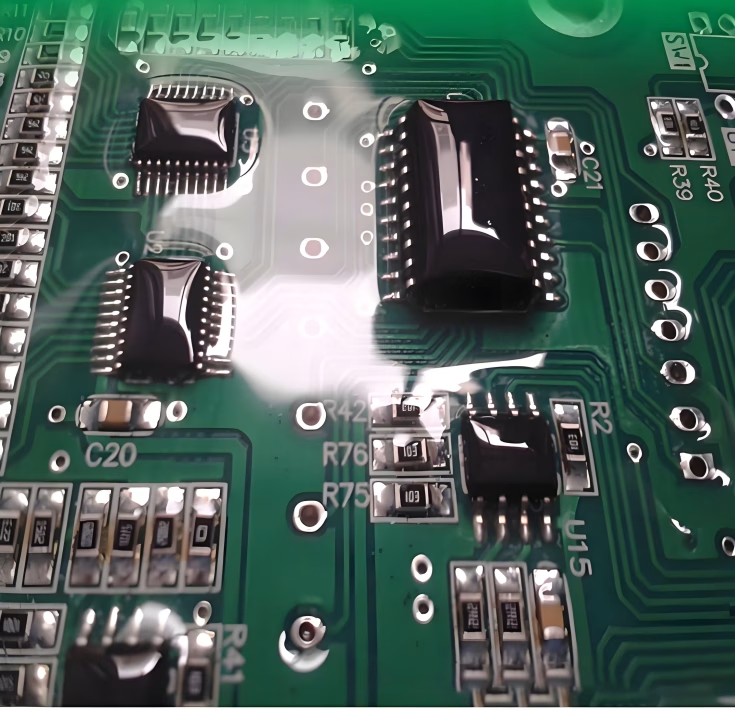

In the rapidly evolving world of electronics, Printed Circuit Board Assembly (PCBA) are the heart of nearly every device, from consumer gadgets to critical aerospace systems. Their performance and reliability are paramount. However, these intricate electronic components are inherently vulnerable to a myriad of environmental stressors, including moisture, dust, chemicals, and temperature fluctuations. This is where PCBA conformal coating steps in as a vital protective measure.

A PCBA protective coating is a thin, polymeric film that “conforms” to the contours of a circuit board, encapsulating components and solder joints. Its primary role is to safeguard the delicate electronics from harsh operating conditions, thereby extending the lifespan and ensuring the consistent performance of the device. This comprehensive guide will delve into the world of PCBA conformal coating, exploring its benefits, various material types, application methods, process steps, and critical considerations for achieving optimal protection for your circuit board.

1. What is PCBA Conformal Coating?

Conformal coating for PCBA is a specialized thin, non-conductive dielectric layer, typically applied to electronic circuit boards. This polymeric film, ranging from 25 to 250 micrometers (0.001 to 0.01 inches) in thickness, acts as a protective barrier against environmental aggressors. Unlike potting or encapsulation, which completely encase the PCBA in a thick, often rigid material, conformal coating preserves the board’s profile and weight, allowing for easier inspection and potential rework.

The main purpose of a PCB board coating is to prevent physical damage and electrical failures caused by factors such as humidity, condensation, corrosive gases, dust, dirt, and vibrations. By conforming to the shape of the components, it forms a protective blanket that isolates circuits and prevents external elements from compromising their integrity.

2. Why PCBA Conformal Coating is Essential?

The application of conforming coating for PCBA is not merely an option but often a necessity for enhancing the reliability and longevity of electronic products, especially those operating in challenging environments such as marine, aerospace, automotive, and industrial settings. Here ‘s why this PCBA protective coating is crucial:

- Moisture and Humidity Protection:One of the most significant threats to electronics is moisture. Conformal coatings create an effective barrier against humidity and condensation, preventing corrosion of traces and components, and mitigating the risk of short circuits or electrochemical migration.

- Contaminant Defense: Dust, dirt, grime, and other airborne particles can accumulate on a PCBA, leading to electrical leakage paths or physical damage. The coating seals the surface, preventing such contaminants from reaching sensitive areas. It also offers protection against more aggressive elements like salt spray and industrial pollutants.

- Temperature Extremes & Thermal Shock: Coatings can help buffer the effects of rapid temperature changes, reducing mechanical stress on solder joints and components that might otherwise expand and contract at different rates, leading to fatigue failures.

- Mechanical Protection: The protective layer adds a degree of mechanical strength, shielding components from vibration, shock, and abrasion. This is particularly vital for devices subjected to dynamic movements or rough handling.

- Electrical Insulation: Conformal coatings significantly increase the dielectric strength between conductors, preventing arcing, reducing signal leakage, and allowing for closer trace spacing, which can lead to more compact designs. This improved insulation helps maintain signal integrity.

- Increased Product Lifespan:By mitigating all the aforementioned environmental and mechanical stressors, circuit board conformal coating directly contributes to a longer, more reliable operating life for the electronic device, reducing warranty claims and improving customer satisfaction .

- Compliance with Industry Standards:Many industries require conformal coating to meet specific performance standards, such as IPC-CC-830, ensuring the highest level of protection and reliability.

3. Types of Conformal Coating Materials

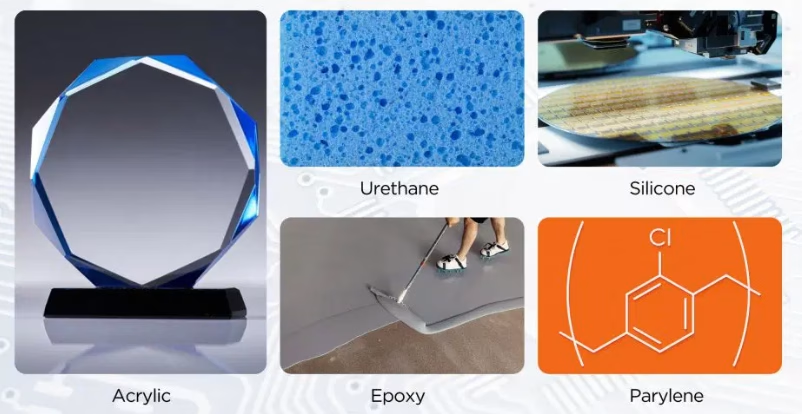

The choice of PCBA coating material is critical and depends heavily on the specific application requirements, environmental conditions, and desired level of protection. Each type offers a unique balance of properties, benefits, and drawbacks. The IPC-CC-830 standard categorizes these materials into distinct types:

3.1 Common Con formal Coating Types

1) Acrylic (AR): Known for their ease of application, fast curing, and excellent moisture resistance. Acrylic coatings are also simple to rework, as they can be easily removed with solvents. However , they offer limited resistance to solvents, chemicals, and abrasion, and their temperature range is typically -55°C to 130°C.

2) Urethane (UR): These coatings provide superior abrasion and chemical resistance once fully cured, making them highly durable. They also offer excellent moisture protection and a good temperature range of -65°C to 130°C. The main drawback is their difficulty in rework due to their hardness and solvent resistance.

3) Silicone (SR): Offering a wide operating temperature range (-65°C to 200°C), silicones are highly flexible and provide excellent moisture resistance. Their elasticity makes them ideal for applications involving thermal cycling or vibration. However, they can be difficult to rework and have high friction characteristics.

4) Epoxy (ER): Epoxy coatings are extremely hard, rigid, and offer outstanding chemical and abrasion resistance . They provide strong adhesion to many substrates. Their rigidity, however, can stress delicate components during temperature changes, and they are notoriously difficult to rework.

5) Parylene (XY): Applied via a unique vapor deposition polymerization process, Parylene coatings offer exceptional barrier protection. They are extremely thin (down to 0.0005-0.002 inches), pinhole-free, and provide superior chemical, moisture, and dielectric properties. Parylene is considered the highest level of protection but is also the most expensive and difficult to rework due to its integral bond with the substrate.

3.2 Comparative Analysis of Conformal Coating Materials

To aid in selection, the following table summarizes key properties and characteristics of the primary PCBA coating material types:

| Coating Type | Acrylic (AR) | Urethane (UR) | Silicone (SR) | Epoxy (ER) | Parylene (XY) |

| Reworkability | Excellent (Solvent Soluble) | Difficult | Difficult | Very Difficult | Extremely Difficult |

| Protection Level (Environmental) | Good | Excellent | Very Good | Excellent | Superior |

| Cost | Low | Medium | High | Medium | Very High |

| Temperature Range (°C) | -55 to 130 | -65 to 130 | -65 to 200 | -55 to 150 | -200 to 200 |

| Dielectric Strength (V/mil) | ~1500 | ~2000-3000 | ~1000-1500 | ~1000- 2500 | ~5000 -7000 |

| Moisture Resistance | Good | Excellent | Very Good | Excellent | Superior |

| Abrasion Resistance | Poor | Excellent | Fair | Excellent | Good |

| Chemical Resistance | Poor | Excellent | Fair | Excellent | Excellent |

| Flexibility | Medium | Medium | Excellent | Poor (Rigid) | Good |

| Adhesion | Good | Excellent | Good | Excellent | Excellent |

| Cure Method | Room Temp (Fast) | Heat/Room Temp | Heat/Room Temp | Heat/Room Temp | Vapor Deposition (No Cure) |

4. PCBA Conformal Coating Application Methods

The method of applying PCB assembly conformal coating significantly impacts the quality, consistency, and cost-effectiveness of the protective layer. Various techniques are available, each with its own advantages and suitable for different production volumes and PCBA complexities.

Primary Application Methods for Conformal Coating

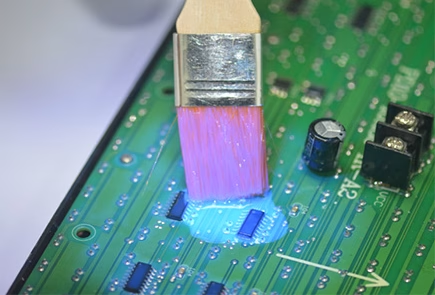

1) Brush Coating: This is the simplest and most manual method, typically used for small batches, rework, or localized repairs. A small amount of coating material is applied directly to the PCBA using a brush. While cost-effective for low volumes, it often results in inconsistent thickness and requires skilled operators.

2) Dip Coating: In this method, the entire PCBA is immersed into a tank of the conformal coating material at a controlled rate, held for a specified dwell time, and then slowly withdrawn. Dip coating is efficient for high-volume production and offers uniform coating on all immersed surfaces. However, it requires significant masking of connectors and non-coated areas, and material waste can be a concern.

3) Spray Coating: Spray application is one of the most common and versatile methods for pcba conformal coating spray.

- Aerosol Spray: Similar to brush coating, aerosol cans are used for small-scale applications, prototypes, or repairs. It’s inexpensive but offers limited control over thickness and uniformity.

- Manual Spray Gun: A step up from aerosol, using a spray gun provides better control but still relies heavily on operator skill.

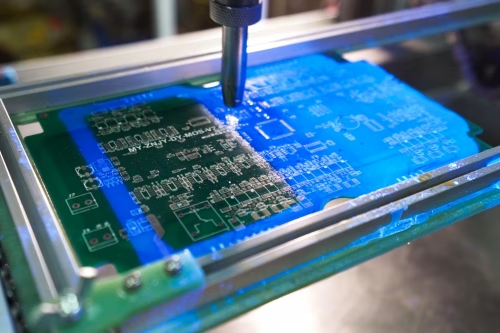

- Automated Selective Robotic Spray:This is the preferred method for medium to high-volume production. Robotic systems precisely spray the coating onto specific areas of the PCBA , minimizing the need for masking and ensuring consistent thickness and coverage. This method is highly efficient, reduces material waste, and is excellent for complex board geometries.

4) Vapor Deposition (for Parylene): Exclusive to Parylene coatings, this method involves placing the PCBAs in a vacuum chamber where solid Parylene dimer is vaporized and then allowed to deposit as a thin, uniform polymeric film. This process creates an exceptionally conformal and pinhole-free coating, even on intricate geometries, without liquid phase. It is a batch process, relatively slow, and involves specialized, expensive equipment.

5. The PCBA Conformal Coating Process

A successful PCBA conformal coating process involves several critical stages, each requiring meticulous attention to detail to ensure optimal adhesion, coverage, and protection .

Key Steps in Conformal Coating Application

1) Cleaning and Surface Preparation: This is perhaps the most crucial step. Any contaminants on the PCBA surface—such as flux residues, oils, dust, or fingerprints—can severely compromise the adhesion of the coating, leading to de-wetting, bubbles, and ultimately, coating failure. Boards must be thoroughly cleaned using appropriate methods (e.g., aqueous wash , solvent cleaning, or plasma treatment) and then completely dried.

2) Masking: Areas that must not be coated (e.g., connectors, test points, optical components, switches, heat sinks, ground points) need to be protected. This is typically achieved using specialized masking tapes, liquid maskants (peelable latex or UV curable), or reusable masking boots/plugs. Precise masking prevents coating material from interfering with component functionality or future connections.

3) Application: Once cleaned and masked, the PCB assembly conformal coating is applied using one of the methods described above (brush, dip, or spray). For multi-coat applications, adequate flash-off time between coats is essential to allow solvents to evaporate and prevent trapping.

4) Curing: After application, the coating needs to cure (dry or polymerize) to achieve its final protective properties. Curing methods vary by material type:

Room Temperature Curing: Many acrylics and some urethanes cure by solvent evaporation or moisture reaction over several hours or days.

Heat Curing: Accelerates the curing process for many materials, including urethanes, silicones, and epoxies.

UV Curing: Utilizes ultraviolet light to rapidly cure specific UV-curable coatings, offering very fast processing times.

5) Inspection: Post-curing, a thorough inspection is performed to verify the quality of the coating. This typically involves:

Visual Inspection: Checking for uniformity, coverage gaps, bubbles, de-wetting, or other defects.

UV Inspection: Most conformal coatings contain a UV tracer, allowing for easy inspection under a black light to ensure complete coverage.

Thickness Measurement: Non-destructive methods (e.g., eddy current or ultrasonic gauges) are used to confirm the coating meets specified thickness requirements.

6) Rework and Repair: Despite best practices, rework may sometimes be necessary. This involves carefully removing the coating from specific areas using solvents, mechanical abrasion, or micro -blasting, performing the repair, and then re-applying the coating to the repaired area. The ease of rework varies greatly with the coating material.

6. Key Considerations for Selection

Choosing the right conformal coating PCBA solution is a multifaceted decision that impacts both performance and cost. Here are critical factors to consider:

- Operating Environment: The most important factor. Will the PCBA face high humidity, extreme temperatures, corrosive chemicals, salt spray, or vibrations? This dictates the required level and type of protection.

- Required Protection Level:What degree of defense is needed against moisture, chemical exposure, abrasion, and electrical insulation? Some applications demand superior barrier properties (e.g., Parylene), while others are satisfied with basic moisture resistance (e.g., Acrylic).

- Component Density and Geometry:Highly populated boards with intricate component layouts may necessitate selective spray or vapor deposition methods for precise, uniform coverage without excessive masking.

- Reworkability:How likely is it that components will need to be replaced or repaired after coating? If rework is a frequent necessity, easily strippable coatings like acrylics might be preferred despite their lower overall protection.

- Curing Method and Production Throughput:The available curing equipment (ovens, UV lamps) and desired production speed will influence material selection. UV-curable coatings offer very fast cycle times, while room-temperature cure materials require longer dwell times.

- Cost:This includes material cost, equipment investment (for automated systems or vapor deposition), labor, and process control expenses. Higher-performance coatings generally come with higher costs.

- Regulatory Compliance: Ensure the chosen coating materials and processes comply with relevant industry standards (e.g., IPC-CC-830), environmental regulations (RoHS, REACH), and safety certifications (UL).

7. Challenges and Best Practices

While invaluable, the PCB assembly conformal coating process can present several challenges. Addressing these with best practices ensures high-quality, reliable protection.

Common Challenges:

- Adhesion Loss:The coating peeling or delaminating from the PCBA, usually due to inadequate cleaning or surface contamination.

- Bubbles and Voids : Trapped air or solvent during application or curing, creating weak spots in the coating.

- De-wetting: The coating pulling away from certain areas, often due to low surface energy on the PCBA or contamination.

- Cracking: The coating developing cracks due to excessive thickness, improper curing, or mechanical stress from component thermal expansion.

- Inconsistent Thickness: Leads to uneven protection and potential electrical issues.

- Masking Errors:Incomplete masking can lead to coating on prohibited areas, affecting functionality or reworkability.

Best Practices for Optimal Results:

- Thorough Cleaning: Always start with a meticulously clean and dry PCBA. Invest in effective cleaning solutions and processes appropriate for the flux types used.

- Precise Masking: Use high-quality masking materials and ensure all non-coating areas are perfectly covered. Automated masking solutions can significantly reduce errors.

- Controlled Application Environment:Maintain stable temperature and humidity in the coating area. Dust-free environments are crucial to prevent contamination.

- Optimized Application Parameters: Calibrate equipment (spray pressures, dip speeds, nozzle types) and maintain consistent coating viscosity to achieve uniform thickness.

- Proper Curing: Follow the manufacturer’s recommendations for curing times and temperatures. Ensure adequate ventilation for solvent-based coatings.

- Rigorous Inspection:Implement systematic inspection processes using UV light and visual checks to identify defects early. Use thickness measurement tools for quality control.

- Operator Training:Ensure all personnel involved in the coating process are thoroughly trained on materials, equipment, and quality standards.

- Material Compatibility:Always verify the compatibility between the coating material and all components on the PCBA, especially sensitive parts or those with unique surface finishes.

8. PCBA Conformal Coating FAQs

Its main purpose is to protect electronic circuit boards from environmental aggressors like moisture, dust, chemicals, and temperature extremes, thereby preventing corrosion, short circuits, and mechanical damage, and extending the product’s lifespan.

Most PCBAs can be coated, but critical areas like connectors, test points, optical components, switches, and heat sinks must be carefully masked to prevent coating, as it could interfere with their functionality or future connections.

Selection depends on the operating environment, required protection level, reworkability needs, component density, curing method availability, and cost. Refer to the comparative table in this guide for material properties.

Yes, rework is generally possible, but its ease varies significantly by coating type. Acrylics are the easiest to remove (often with solvents), while urethanes, silicones , epoxies, and especially Parylene are much more challenging and may require mechanical or specialized chemical removal methods.

The typical thickness ranges from 25 to 250 micrometers (0.001 to 0.01 inches), depending on the coating material and application requirements. Parylene coatings can be even thinner, often less than 25 micrometers.

9. Summary

PCBA conformal coating is an indispensable process for safeguarding the reliability and extending the operational life of modern electronic assemblies. By applying a thin, protective polymer film, circuit boards are shielded from a multitude of environmental hazards, including moisture, contaminants, temperature fluctuations, and mechanical stress. The selection of the appropriate PCBA coating material—whether acrylic, urethane, silicone, epoxy, or Parylene—hinges on a careful evaluation of the operating environment, required protection level, and reworkability considerations.

Furthermore, the chosen PCBA conformal coating process, from meticulous cleaning and precise masking to controlled application and thorough inspection, is paramount to achieving a high-quality, defect-free protective layer. Adhering to best practices and understanding the nuances of each material and application method ensures that the pcb assembly conformal coating performs its vital role in enhancing product durability and performance in demanding applications.

Key Takeaways

- PCBA conformal coating is a thin, polymeric layer crucial for protecting electronic circuits from environmental damage and extending their lifespan.

- It provides vital defense against moisture, dust, chemicals, temperature extremes, mechanical shock, and improves electrical insulation.

- Different coating materials (Acrylic, Urethane, Silicone, Epoxy, Parylene) offer varied properties in terms of protection, flexibility, temperature resistance, and reworkability.

- Application methods range from manual brushing and dipping to automated selective spray and specialized vapor deposition, chosen based on volume and complexity.

- A robust PCBAconformal coating process includes thorough cleaning, precise masking, controlled application, proper curing, and diligent inspection to ensure effectiveness.

- Careful consideration of the operating environment, cost, and rework needs is essential for selecting the optimal conformal coating for PCBA.

Table of Contents

Get Your PCB Quote!