Top 5 Benefits of Partnering with a PCB Assembly and Manufacturing Company

Partnering with the established PCB assembly and manufacturing company means that solutions are always at hand. This enhances the quality of finished products.

Get Your PCB Quote!

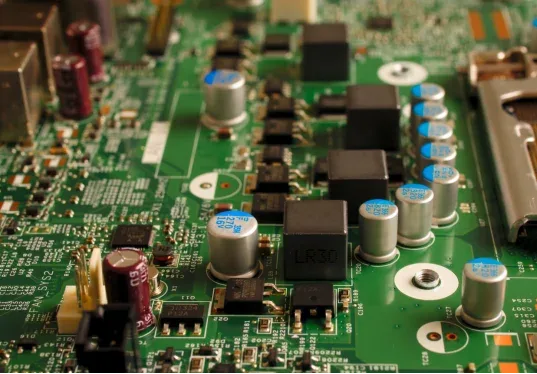

In a world increasingly powered by electronics, the quality and reliability of printed circuit boards can make or break your final product. The quicker the world of innovation and time-to-market opens up to squeeze the partners, a strategic rather than a mere logistical decision becomes of paramount importance. And that is where a professional PCB assembly and manufacturing company can level the playing field for you.

Through the very latest technologies and scalable production capacities, the advantages offered go far beyond mere convenience. If you are a startup trying to develop your very first prototype or are an established brand moving into new markets, expert involvement makes for risk reduction and ensures quality.

Let us run through the top five reasons why this partnership is beneficial and how it can affect your business in the long run.

1. Accelerate Product Development

Another immediate advantage is in speed and efficiency. Working with a full-service provider gets your products to market quicker. This implies that you do not need to handle multiple vendors or complicated supply chains that may lead to delays and errors at a very high cost.

Integrated services entail a fast exchange of ideas among designers, engineers, and production experts. The faster these teams collaborate and work together, the quicker the concept is turned into the finished product. Any design change or component alteration is incorporated smoothly, thereby reducing lost time.

When a timely introduction into the market means success for a product, fast prototyping and revisions must be turned around. This would make them responsive to changing customer requirements, which in turn is their competitive advantage.

2. Improved Quality Control

In electronics, quality is everything. A small fault in a circuit could cause a complete system failure, potentially bringing about loss of reputation and money. A specialized partner implements stringent quality measures for every step of the production cycle, from design verification to production testing.

Professional teams, with solid training in the specific industry’s requirements, ensure that every single surface mount PCB conforms to set standards. They usually maintain infrastructure that incorporates in-house testing facilities simulating actual operating conditions. This lets us catch problems early, way before your product gets to the end user.

More than just fixing flaws, quality assurance is about building things right from day one. Right from sourcing materials up until the final inspection, a quality manufacturing partner will consider durability, reliability, and performance as their primary concerns for each and every board that they put together.

3. Access to Advanced Technologies

In the present economic scenario, obsolete technologies could only keep your business yards behind the competition. Working with a dedicated team would mean that you would be able to make use of innovative tools and processes, which may be far too expensive or unrealistic to maintain within the company.

State-of-the-art machinery goes a long way for high-density multipliers and multiple-layer contents. Companies that offer SMT PCB board manufacturing usually have the latest placement and soldering machines, which means higher precision and fewer defects.

They also tend to have principles for components and materials, enabling the board designer with a large canvas of designs. This freedom allows for faster iterations and more experimentation without the compromise on quality.

Apart from the hardware advantages, the management teams remain up to pull with worldwide industry trends, including compliance requirements and environmental standards. So, this keeps your products in line with what is expected internationally.

4. Cost Efficiency at Scale

Initially, a barter economy can only be alleged to be an additional cost. At the same time, it starts keeping a record of the superior in due course. With an experienced team, there is effective resource utilization, eliminating wastage which may arise in the in-house trial-and-error way.

Lower manufacturing costs arise through volume discounts on materials, good acquisition methods of procurement, and less rework. Fixing errors or replacing defective parts takes less time and less money, owing to efficient handling of components and fewer defects.

Labour and equipment costs, however, are minimised. That means you don’t have to hire a new team or train one; neither will you have to buy or maintain specialised equipment. That frees up more of your budget for things like promotion and product development.

This is a really important factor for small and medium businesses. Demand-based production scaling can happen through the partner whilst keeping costs locked down: From a small PCB assembly and manufacturing run upward to full production.

5. Finding the Right Manufacturing Partner

Picking the perfect team brings the implementation of these benefits. The main area for assessment is their past work background. A recognizable provider should be able to furnish good references, acquired certifications, and experience that pertains to your industry.

Also, consider how they communicate and their project management style. The best partners make sure you’re always in the loop. Timing, costs, and quality checks must be completely transparent: the hallmark of a trustworthy firm.

The next checkpoint on your list should be the abilities, technically speaking. Do they provide support for the development of prototypes for circuit boards? Are they able to work on simple or complicated designs on boards? Can they grow along with your business?

That type of partner won’t simply produce your boards. They will also share insights, bringing improvements to your product and fortifying your business.

6. Summary

Above all, the speed, precision, and reliability of current-day movements matter. Partnering with the established PCB assembly and manufacturing company means that solutions are always at hand. This frees up resources while enhancing the quality of finishes and speeding up the time to market.

More importantly, it allows the team to innovate, where real value lies. Be it cutting-edge devices or makeshift industrial equipment, this collaboration helps you get an extra edge.

Merging your ideas with the know-how and infrastructure of a chosen partner gives your business a global competitive edge. Smart manufacturing is no longer an option–it’s a pathway to advancement.

Consult industrial experts who can get your boards up and running and discover your potential today.

Get Your PCB Quote!