Top Trends in PCB Manufacturing and What to Expect from Printed Circuit Board Manufacturers

PCB trends: miniaturization, advanced materials, sustainability, embedded components, 3D printing, automation, flexible PCBs & thermal management.

Get Your PCB Quote!

Table of Contents

- 1. Miniaturisatie en PCB's met hogere dichtheid

- 2. Gebruik van geavanceerde materialen

- 3. Nadruk op duurzaamheid en groene productie

- 4. Integratie van ingebedde componenten

- 5. Vooruitgang in additieve productie en 3D-printen

- 6. Automatisering en Industrie 4.0

- 7. Flexibele en rigide-flexibele PCB's

- 8. Verbeterde oplossingen voor thermisch beheer

- Conclusie

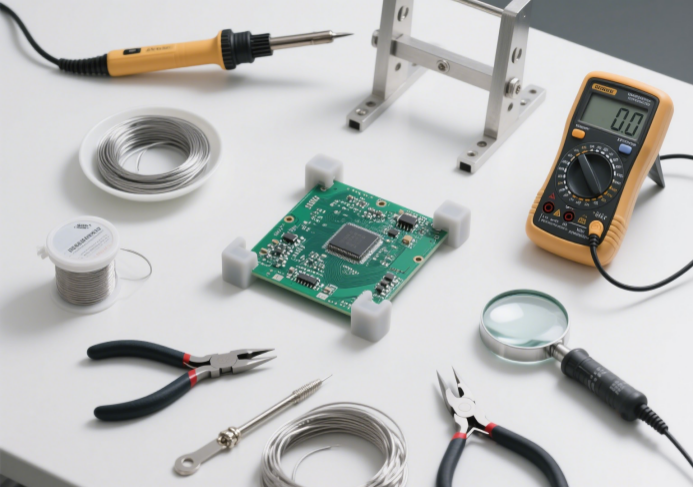

Electronic technology develops at a fast pace with the printed circuit board (PCB) serving as the essential element within every electronic device. The PCB manufacturing industry progresses alongside technological development which drives innovations that determine how circuit boards are created and assembled. Staying competitive and delivering modern solutions requires both businesses and engineers to understand the current trends in circuit board manufacturing.

This blog discusses leading trends affecting manufacturing and future developments expected from printed circuit board makers.

1.Miniaturization and Higher Density PCBs

PCB manufacturing today is experiencing a strong movement toward creating smaller electronic components. As electronic devices become smaller yet more powerful with additional features they require PCBs that fit more components into reduced space. The industry has seen an increase in high-density interconnect (HDI) PCBs that enable complex circuit patterns to fit onto compact boards.

Advanced technologies including microvias (small holes on the board) and narrower trace widths help manufacturers reach higher component density. Through this evolution PCBs become more compact and achieve better electrical performance with enhanced signal integrity which benefits high-speed technologies like 5G and IoT devices.

2.Use of Advanced Materials

The majority of traditional printed circuit boards utilized FR-4 which consists of glass-reinforced epoxy laminate for their composition. Manufacturers are transitioning to advanced materials with superior thermal management, mechanical strength, and electrical performance as performance requirements grow.

Manufacturers are showing increased interest in Rogers, Teflon-based laminates and polyimide substrates for PCB production. The advanced materials deliver unmatched signal integrity for high-frequency circuits along with improved heat dissipation for power electronics which makes them perfect for aerospace, automotive, and telecommunications applications.

3.Emphasis on Sustainability and Green Manufacturing

The manufacturing is one of many industries impacted by environmental concerns. Manufacturers of printed circuit boards are progressively implementing environmentally sustainable methods to minimize waste and environmental effects.

Manufacturers now implement lead-free solder while recycling copper and other materials. They also use energy-efficient machines for production. Various manufacturers are transitioning to biodegradable PCB substrates while minimizing hazardous chemical use during production.

The push from both consumers and regulatory bodies for greener products makes sustainability essential when picking a PCB supplier.

4.Integration of Embedded Components

Manufacturers are increasingly embedding both passive and active components straight into PCB substrates as part of a rising trend in electronics design. Embedded elements such as resistors, capacitors and sensors enable the creation of smaller designs and boost electrical performance.

By minimizing external parts and assembly procedures this technique lowers manufacturing expenses and enhances product reliability. The practice of embedding components into PCB substrates stands out especially in industries such as medical devices, military electronics and small consumer electronics.

5.Advances in Additive Manufacturing and 3D Printing

The field of 3D printing technology continues to transform multiple manufacturing areas with PCB production also experiencing revolutionary changes. Additive manufacturing enables swift prototyping while producing complex shapes that are beyond the capability of traditional subtractive methods.

3D printed PCBs remain in the early phase of mass production yet they provide advantages including quicker production cycles while enabling customization and minimizing material waste. The development of this technology will reach maturity while expanding its reach thus creating new opportunities for designers and circuit board manufacturers.

6.Automation and Industry 4.0

Automation is transforming PCB fabrication lines worldwide. Robotics combined with AI and IoT sensors to drive perfection in smart factory automation while reducing mistakes and boosting production speed.

Manufacturing companies use data analytics to optimize their workflows and predict maintenance needs, which helps them drop time-out. Industry 4.0 transforms manufacturing processes to produce lesser effectiveness as well as bettered quality control and product traceability.

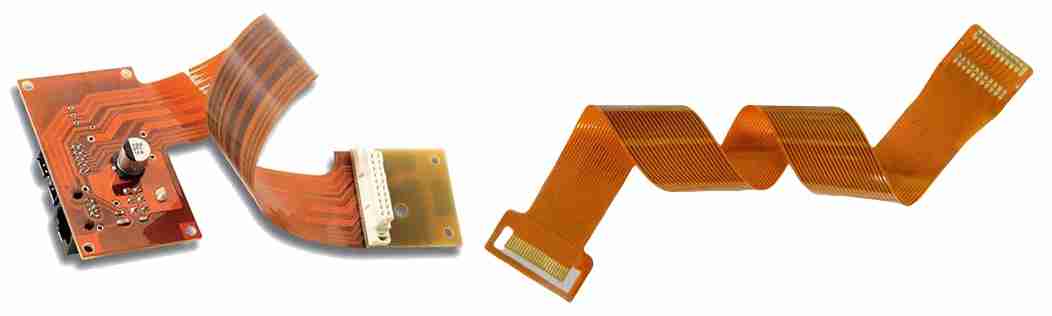

7.Flexible and Rigid-Flex PCBs

Flexible PCBs vs. Rigid-Flex Circuit Boards

The demand for flexible and rigid- flex PCBs grows because these boards combine strength with design versatility. These PCBs maintain their performance while bending and folding which makes them ideal for usage in compact electronic devices as well as medical implants and wearable technology.

Manufacturers are developing advanced production techniques for multilayer flexible circuits that merge rigid boards’ stability with flexible boards’ adaptability. As products evolve towards greater complexity they will need more adaptable PCB solutions which will speed up this trend.

8.Enhanced Thermal Management Solutions

Today’s electronics generate higher power densities which makes controlling PCB heat dissipation crucial. Poor thermal management systems reduce device reliability while shortening their operational lifespan.

To address thermal management problems manufacturers deploy advanced materials such as metal-core PCBs together with heat pipes and thermal vias. Recent PCB layout design advancements aim to enhance airflow and heat distribution. This development allows high-power devices such as LED lighting systems and electric vehicles to function both safely and effectively.

Industry trends show that printed circuit board manufacturers will adapt to the evolving demands of electronics production in the future.

Printed circuit board manufacturers adapt their production methods to keep pace with the technological progress in electronics design and production. These are the expectations you should set when working with modern printed circuit board suppliers:

- Customization and Flexibility:Manufacturers plan to deliver more custom solutions through rapid prototyping and small production runs designed to meet precise industry requirements.

- Quality and Reliability: The combination of automation and improved materials will lead to ongoing enhancements in PCB quality that ensure reliability critical for essential applications.

- Sustainability Initiatives: Manufacturers will implement greener manufacturing approaches while making their environmental policies more transparent.

- Collaborative Design Support: PCB manufacturers are extending their design services to provide engineers with better design tools and improved consultation and testing support.

Conclusion

Advancements in miniaturization and advanced materials together with automation and sustainability practices drive swift and significant changes in the manufacturing sector. Designers, engineers and businesses need updated knowledge about these trends to implement top technology solutions in their product development.

For both startup wearable tech companies and large aerospace corporations’ knowledge of current printed circuit board manufacturing capabilities and future developments will assist in making efficient decisions to cut costs and speed market entry.

Collaborating with innovative manufacturers who prioritize quality enables your electronic products to have a reliable future-proof base.

Table of Contents

- 1. Miniaturisatie en PCB's met hogere dichtheid

- 2. Gebruik van geavanceerde materialen

- 3. Nadruk op duurzaamheid en groene productie

- 4. Integratie van ingebedde componenten

- 5. Vooruitgang in additieve productie en 3D-printen

- 6. Automatisering en Industrie 4.0

- 7. Flexibele en rigide-flexibele PCB's

- 8. Verbeterde oplossingen voor thermisch beheer

- Conclusie

Get Your PCB Quote!